A high temperature and high pressure supercritical carbon dioxide slow strain rate tensile test system

A technology of slow strain rate and carbon dioxide, which is applied in the field of material experimentation, can solve the problems of difficult precise control of key parameters and the decrease of confidence in slow strain rate tensile test results, etc., and achieves the effects of high degree of automation, convenient operation and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

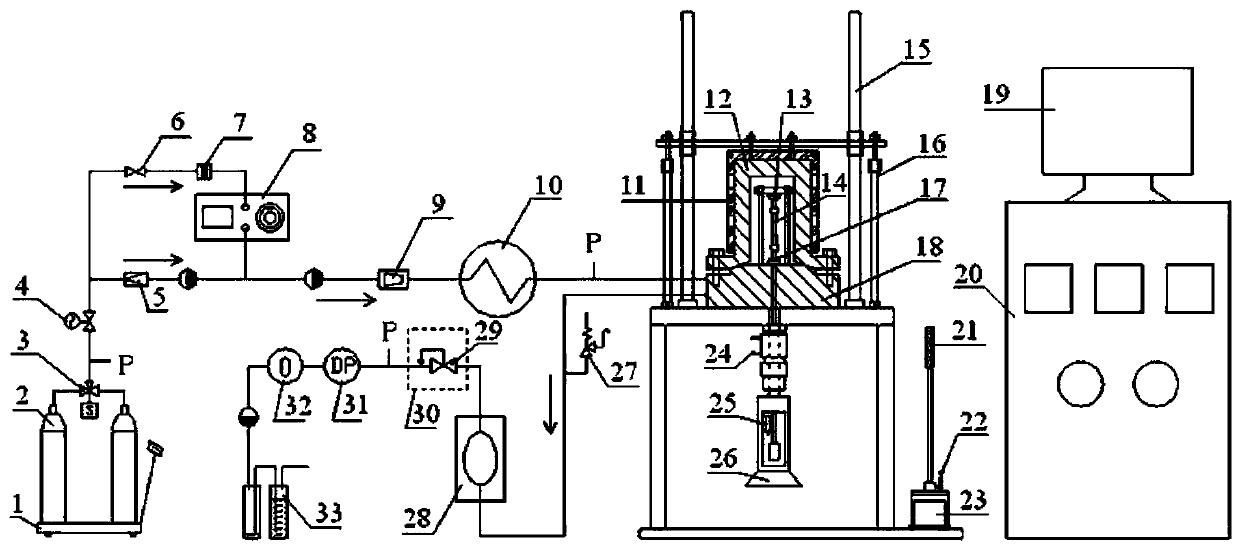

[0027] Such as figure 1 As shown, a high temperature and high pressure supercritical carbon dioxide slow strain rate tensile test system includes a carbon dioxide source, a preheater 10, a reactor, a cooler 28, a regulating device 29, a dew point meter 31, an oxygen analyzer 32 and The exhaust device 33 is composed of two carbon dioxide storage tanks 2 connected in parallel for the carbon dioxide source, and both of them are placed on the electronic scale 1 . The electronic scale 1 transmits the quality signal of the carbon dioxide storage tank 2 to the computer control system to change the opening direction of the electromagnetic reversing valve 3 to ensure the continuous supply of carbon dioxide during the test operation. The outlet of the reversing valve 3 is connected to the pressure gauge and the stop valve 1 4. The above stop valve can be automatically closed when the temperature, pressure and flow rate are abnormal, so as to cut off the carbon dioxide gas source and imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com