Device and method for testing ablation resistance of fluid director

A deflector and ablation-resistant technology, which is used in testing wear resistance, measuring devices, instruments, etc., can solve the problems of difficulty in calculating material ablation, high flight test costs, and unrealistic simulations. Conducive to performance verification, easy to improve and optimize, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The implementation of the present invention will be described in detail below in conjunction with the examples of implementation, but they do not constitute a limitation of the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

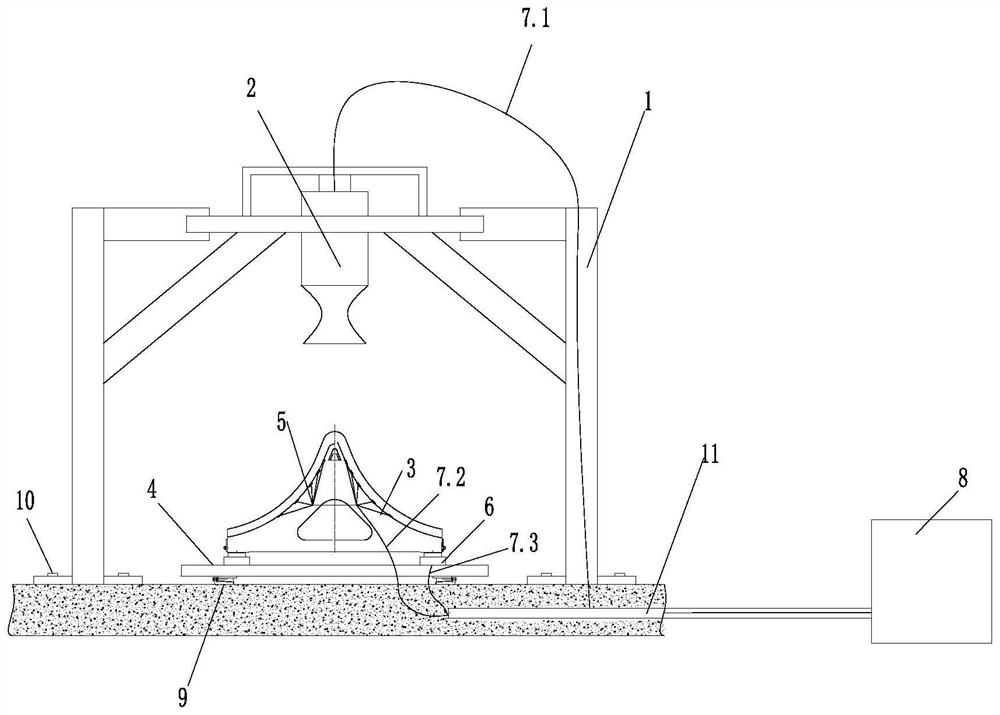

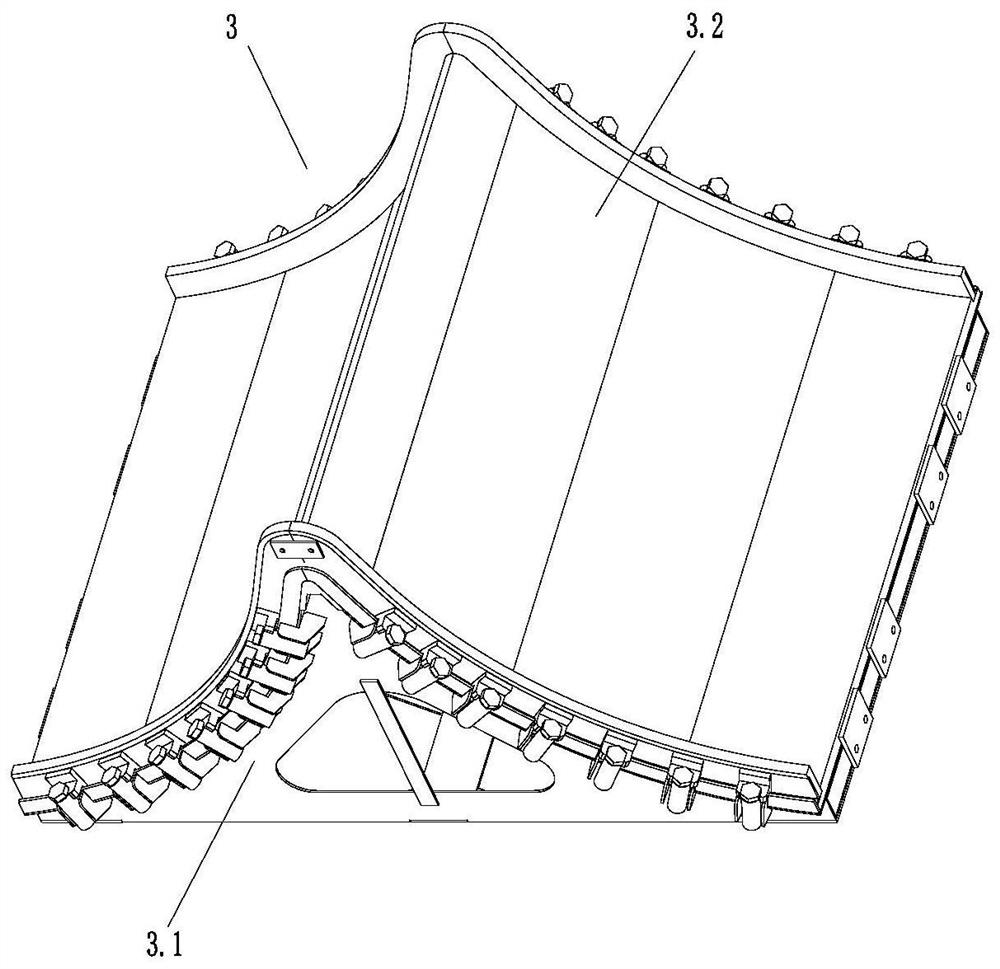

[0031] Such as figure 1 with figure 2 The shown device for testing the ablation resistance of the deflector includes a bench 1, a gas generator 2 is provided in the middle of the bench 1, a deflector 3 is provided directly below the gas generator 2 and a On the test bench 4 supporting the deflector 3, several temperature sensors 5 are arranged on the deflector 3; several pressure sensors 6 are arranged between the bottom of the deflector 3 and the top of the test bench 4, and the temperature sensor 5 The signal output ends of the pressure sensor 6 are respectively connected with the signal input ends of the external control center 8 , and the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com