Evaluation method for the depth of dissolution impact of high-speed railway coarse-grained saline soil subgrade based on stress ratio method

A technology that affects the depth of high-speed railways. It is applied in the fields of instrumentation, geometric CAD, design optimization/simulation, etc. It can solve the problems of soaring engineering investment and increase the workload of survey and design, so as to achieve easy and fast operation, easy parameter testing and implementation process clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

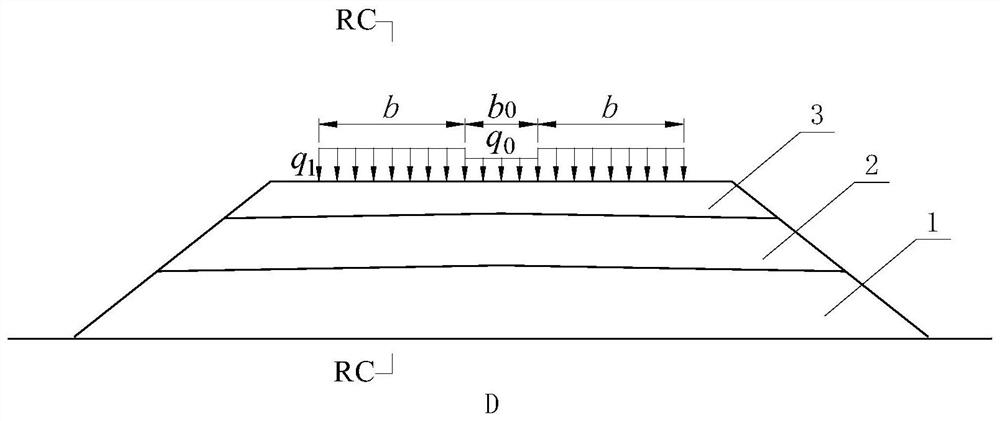

[0044]A high-speed railway embankment is built in a saline soil area, and CRTS I type slab ballastless track is laid on the top surface of the embankment. Most of the borrow areas in this area are saline soil, so it is planned to collect coarse-grained saline soil from a certain site to be used as roadbed filler. Since the depth of dissolution is an important indicator for the calculation of high-speed railway subgrade dissolution, the survey and design It is necessary to reasonably determine the influence depth of subgrade dissolution in coarse-grained saline soil.

[0045] Adopt the method of the present invention below to evaluate this area coarse-grained saline soil embankment dissolution subsidence influence depth, concrete steps are as follows:

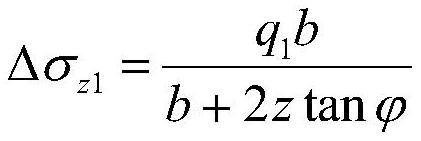

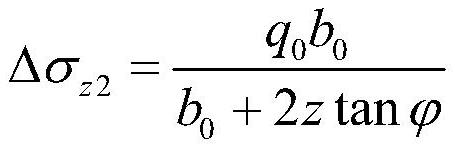

[0046] ① Determine the filling weight of the i-th layer of the roadbed by digging the hole and pouring sand γ i , i=1, 2, 3...; According to the design requirements of CRTS I type slab ballastless track, determine the self-weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com