Bioreactors

A bioreactor and microorganism technology, applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical instruments, etc., can solve the problem of small laboratory area, increased cost and pollution risk And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

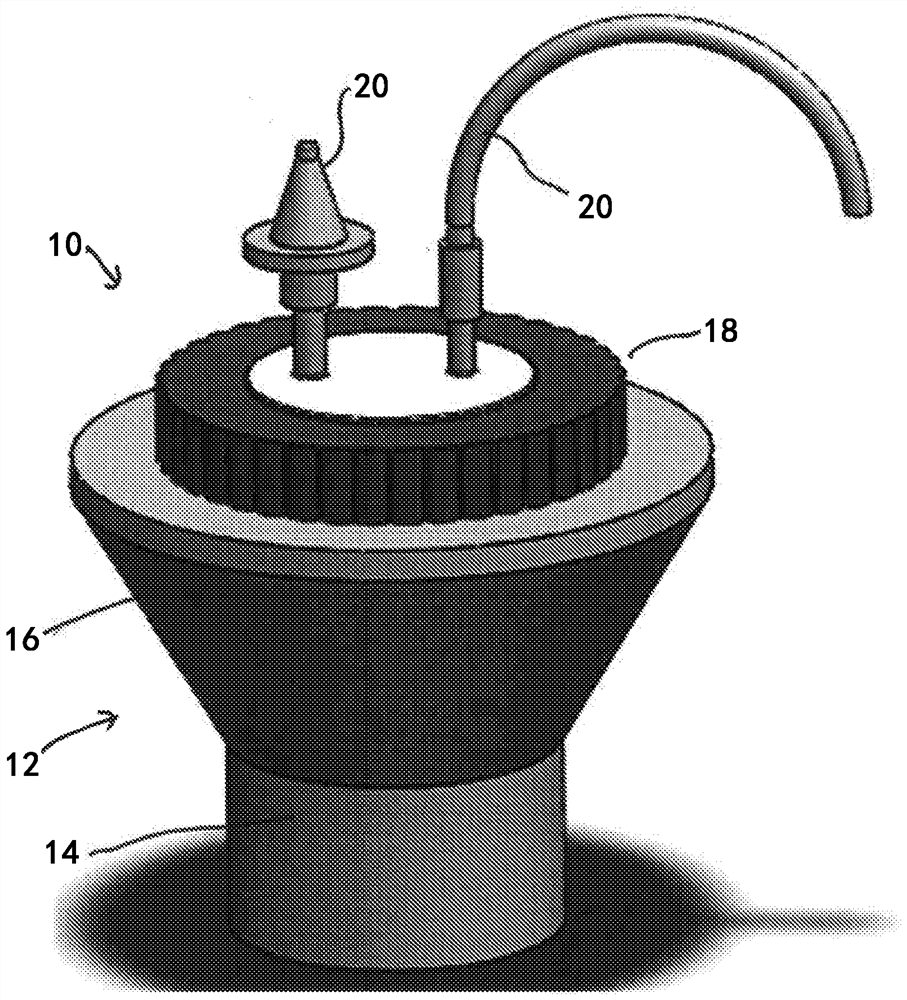

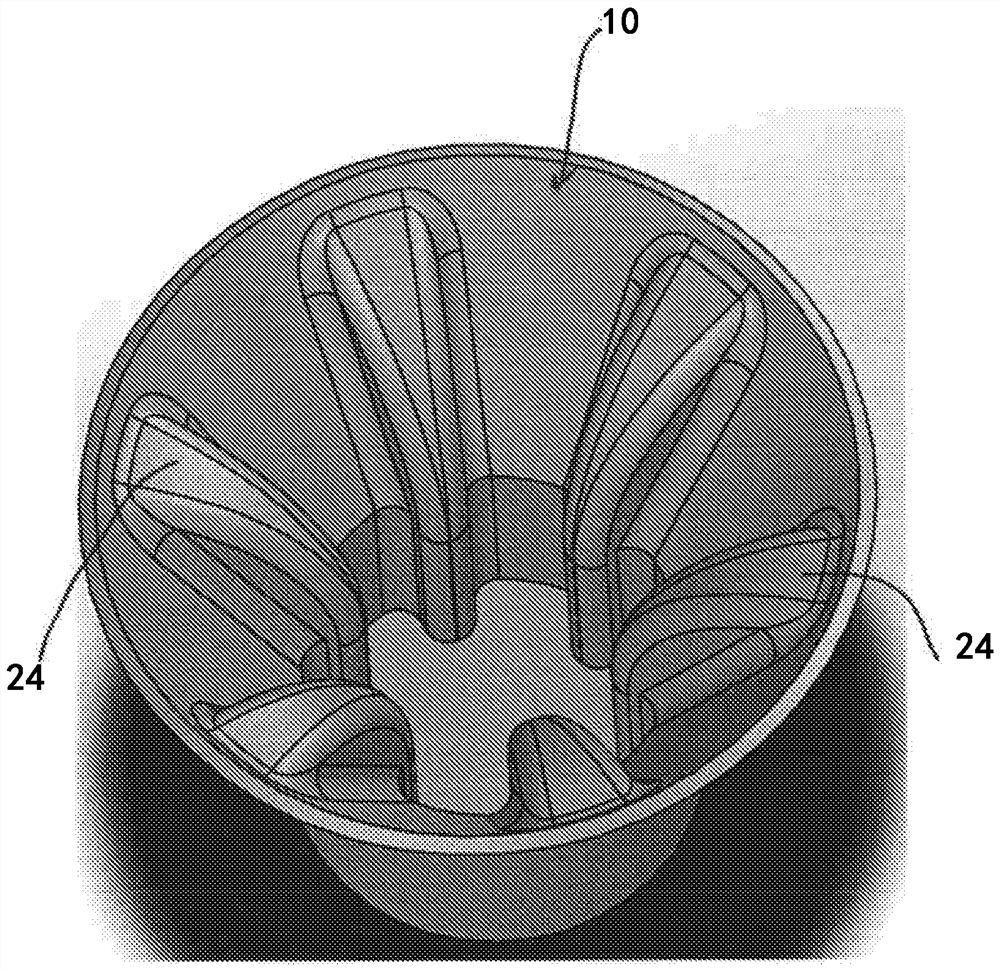

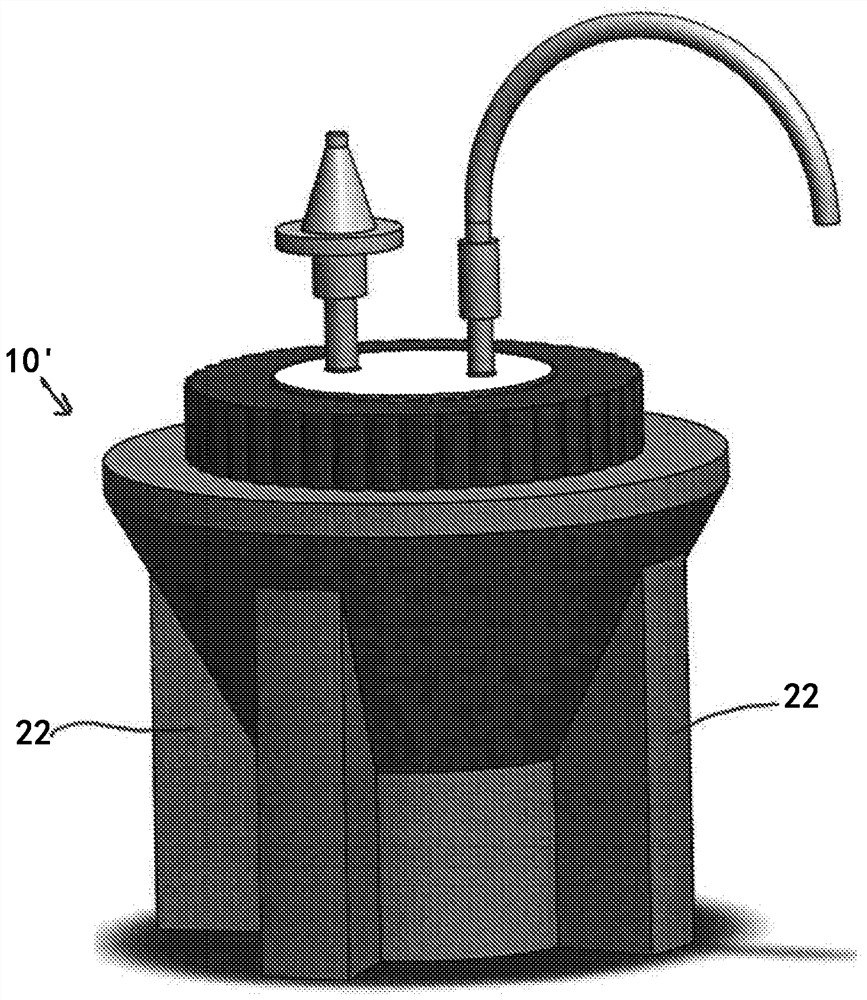

[0017] The present disclosure, together with its objects and advantages thereof, may be better understood by referring to the following description taken in conjunction with the accompanying drawings, in which like reference numerals designate like elements throughout.

[0018] The initial seed cell culture has a relatively low volume, eg, about 10 ml or less. Without being bound by theory, the proximity of cells in culture may be beneficial for growth. Thus, low volume initial seed cultures may benefit from being introduced into containers of relatively small volume during the initial growth phase and subsequently, successively (one or more times) transferred to (one or more) after growth. ) higher volume containers. However, such transfers result in increased cost, increased process complexity, and increased risk of contamination.

[0019] While containers such as bottles can be used instead of bags, conventional bottles also require multiple transfers of the seed volume i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com