Welding machine output mechanism for special shaped finned tube

A special-shaped finned tube and output mechanism technology, used in applications, household appliances, tubular objects, etc., can solve the problems of poor heat dissipation, low high-frequency power, thin structure, etc., to ensure heat dissipation, reliability, and simple design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to better understand the technical solution of the present invention, the following will be described in detail through specific examples:

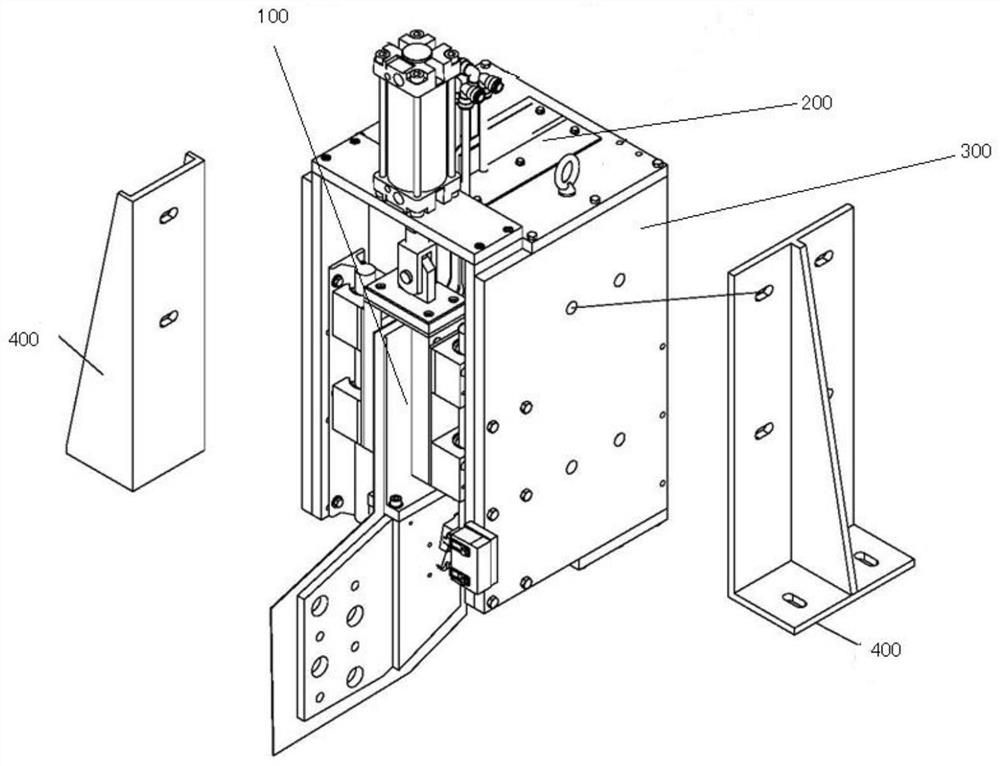

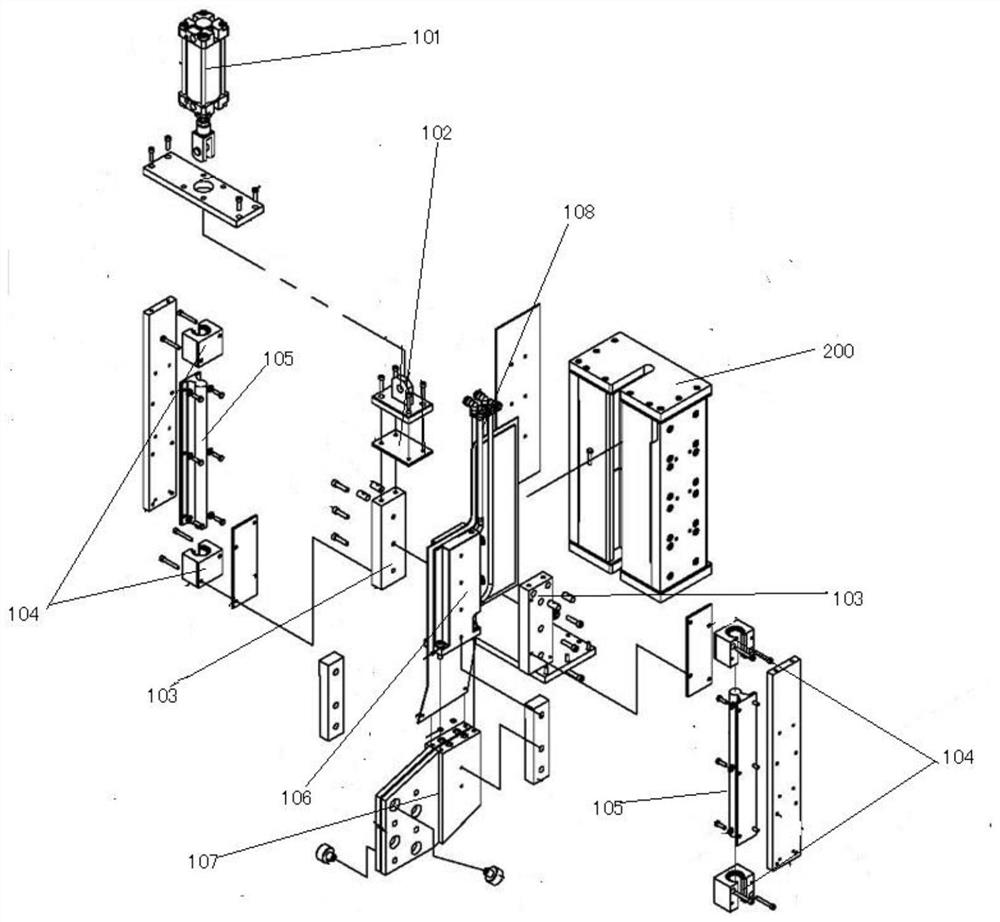

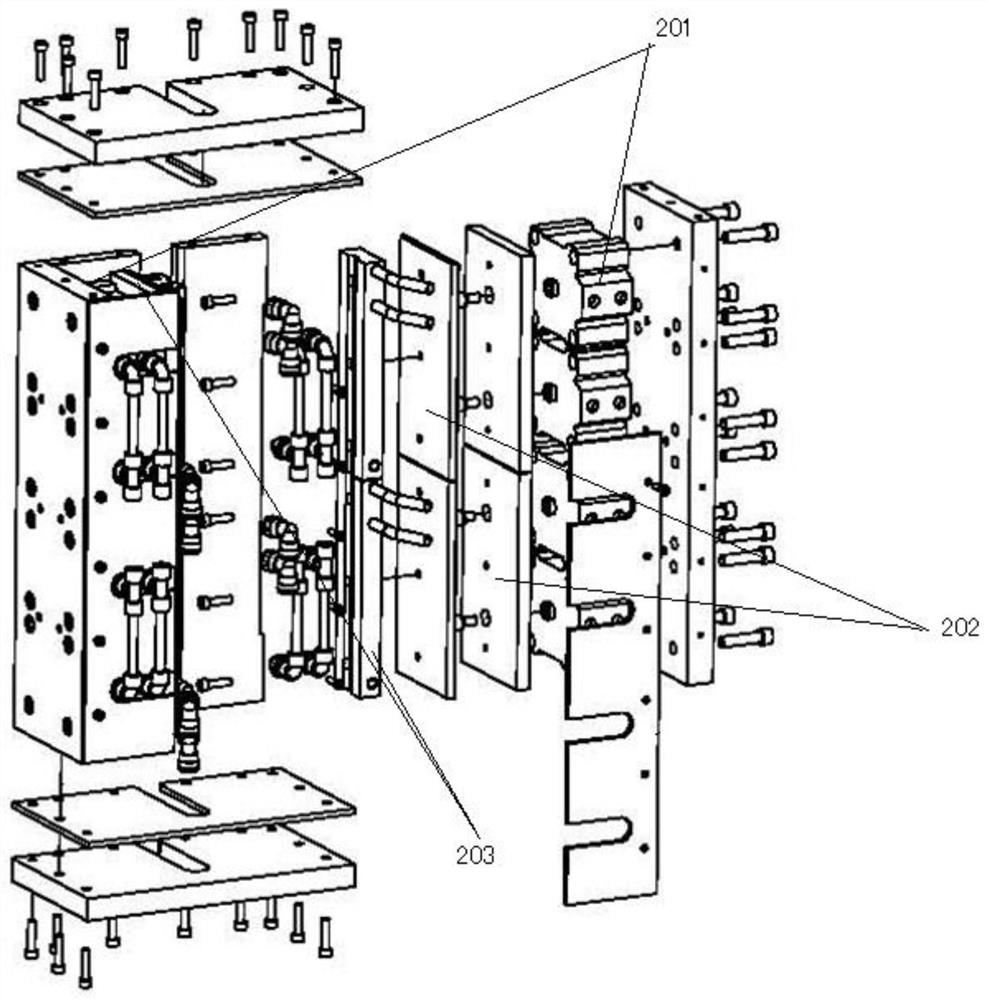

[0033] see Figure 1-Figure 9 , the present invention, a welder output mechanism for special-shaped finned tubes, including a conductive copper block assembly 100, a clamp assembly 200, and a shell insulation assembly 300, the conductive copper block assembly 100 includes a lifting cylinder 101, a first intermediate connection insulation block 102, the second intermediate connection insulating block 103, the third intermediate connection insulating block 104, the cylinder slide rail 105, the conductive copper block 106 and the output row 107; the lifting cylinder 101 passes through the first intermediate connection insulating block 102 and is fixed on the conductive copper The second intermediate connecting insulating block 103 on both sides of the block is fixedly connected; the second intermediate connecting insulating b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com