An intelligent error-proof press-fitting device and method

An intelligent press and error-proof technology, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of high labor intensity, low assembly efficiency, and limited labor skill level of assembly workers, so as to reduce the labor force of workers. Strength, the effect of ensuring the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

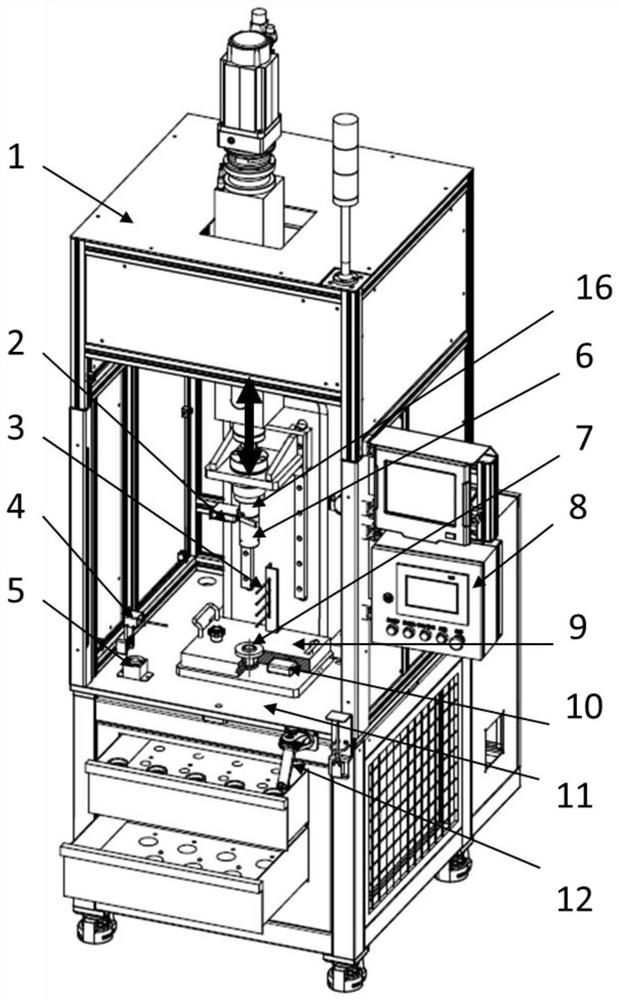

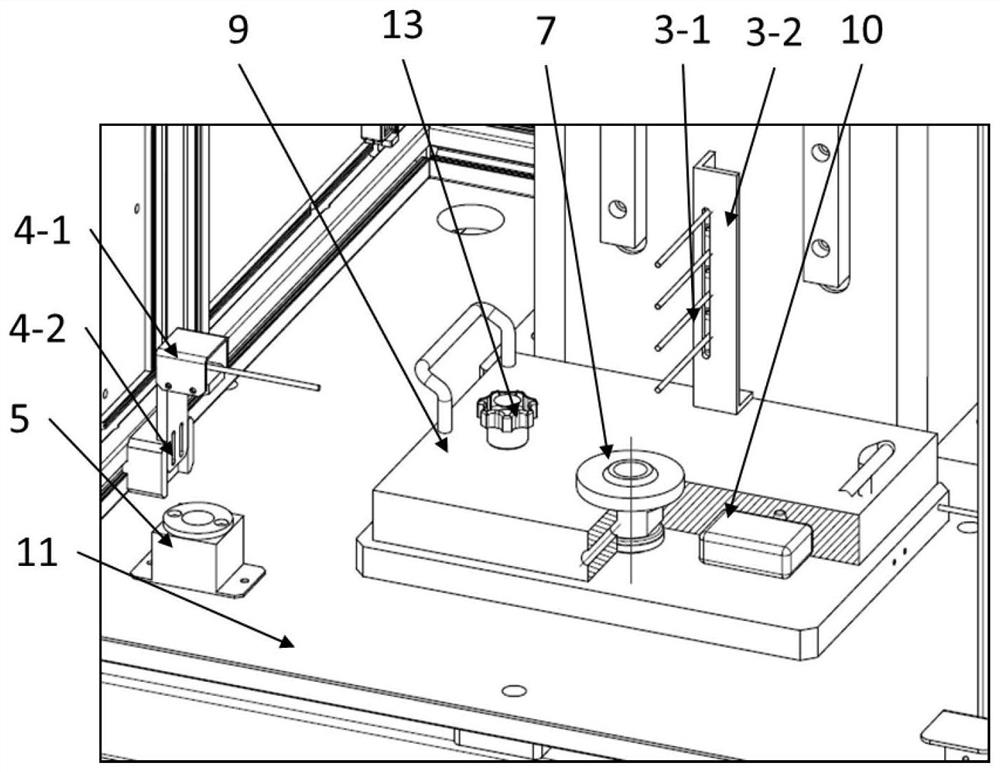

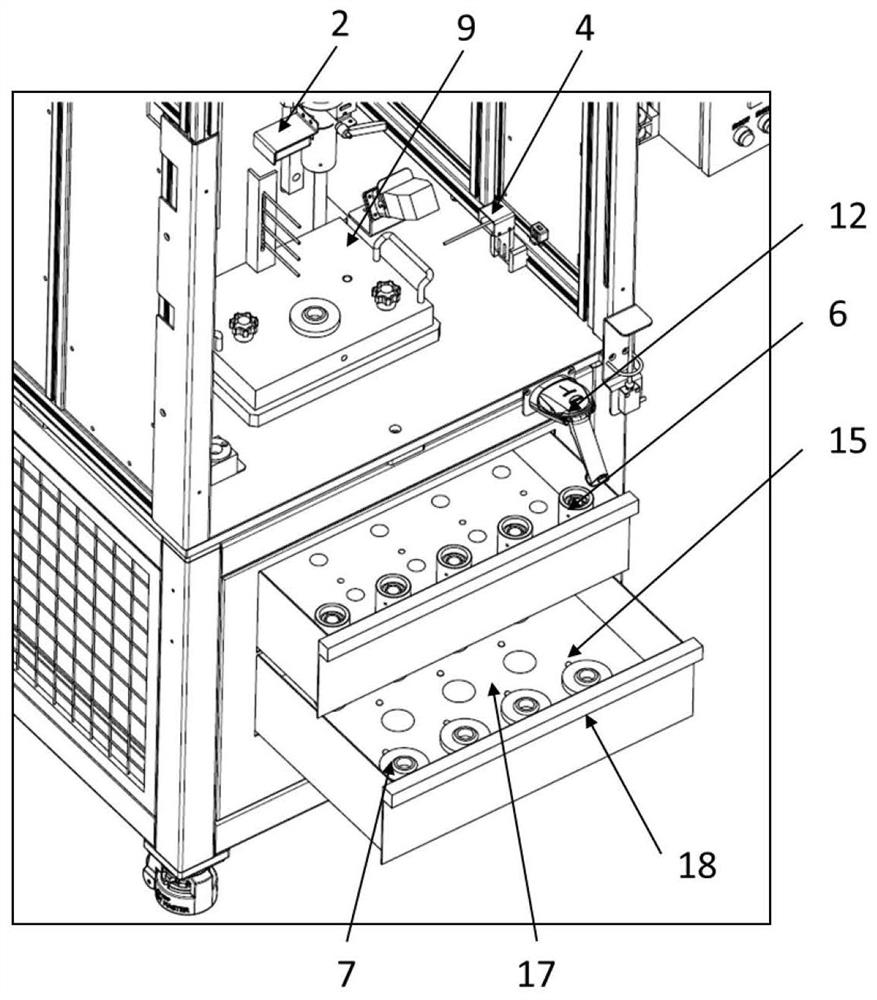

[0060] refer to figure 1 , a preferred embodiment of the present invention provides an intelligent error-proof press-fitting device, including an intelligent press body 1 provided with a controller, an HMI human-machine interface 8 connected to the controller signal, and also includes:

[0061] The upper indenter detection component 2 is installed on the upper indenter quick-change interface 16 of the intelligent press body 1, and is used to detect whether the installed indenter 6 meets the set specifications;

[0062] The guide column in-position detection component 3 is installed on the rear side of the press working platform 11 of the intelligent press body 1 and away from the operator's op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com