Feeding and discharging dual-grabbing manipulator

A technology for grabbing manipulators and material clips, which is applied in the direction of conveyor objects, transportation and packaging, etc. It can solve the problems that one person cannot operate multiple machines, and achieves the effect of wide application range, simple structure and accelerated automation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. The described embodiments are only illustrations and explanations of the present invention, and do not constitute the only limitation of the present invention.

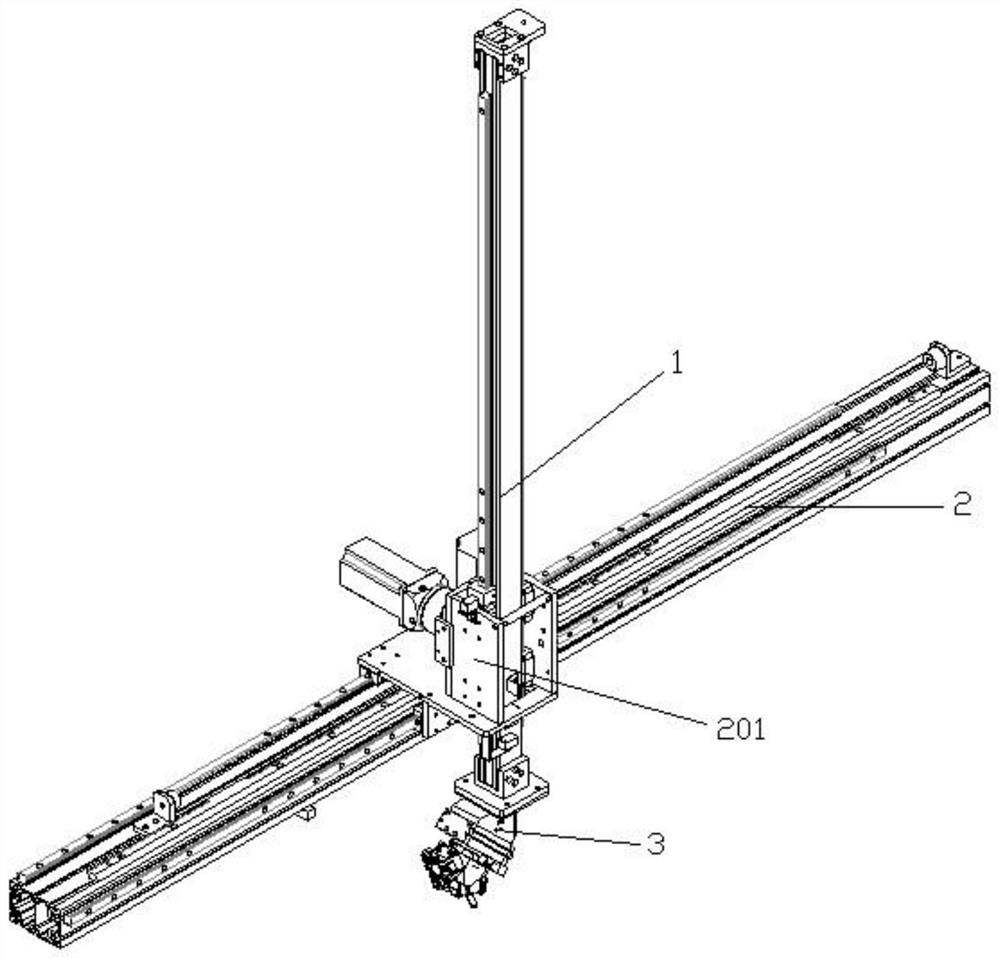

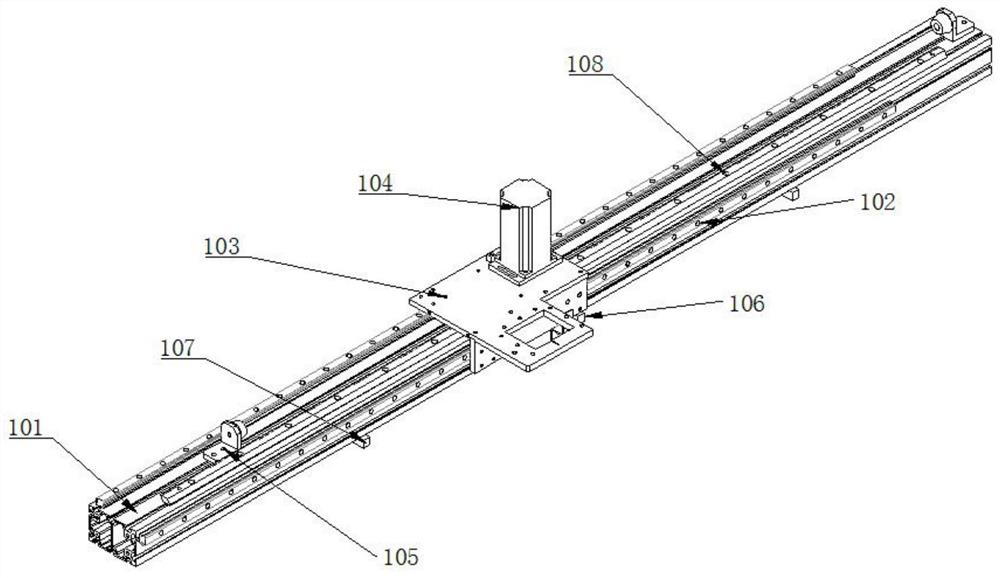

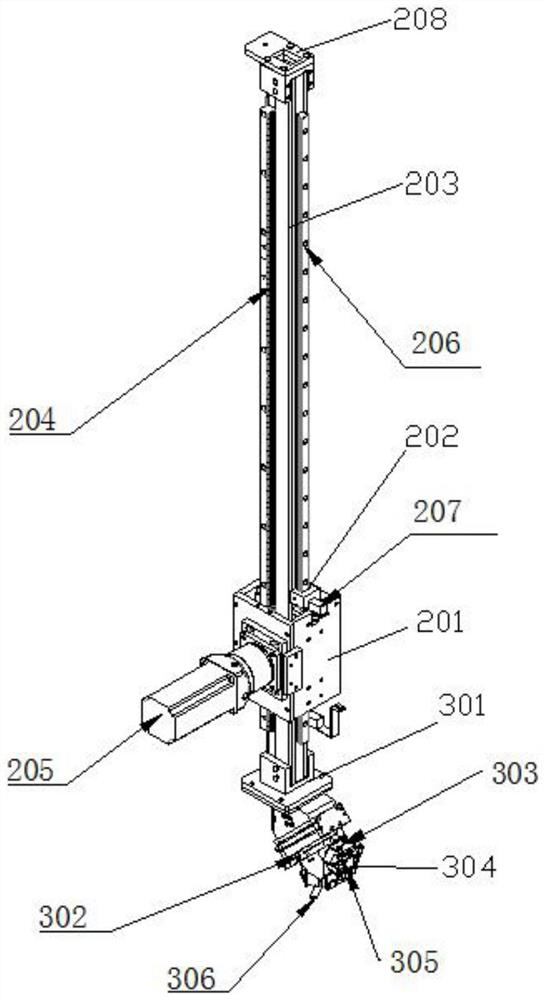

[0016] Such as Figure 1-Figure 5 As shown, this embodiment includes a translation assembly 1, a lifting assembly 2, and a double-claw reversing clamping tooth mechanism 3. The translation assembly includes an aluminum profile base 101, and the aluminum profile base 101 is provided with a pair of linear guide rails arranged in parallel. 102, a straight rack 108 is correspondingly arranged between the two linear guide rails 102, a translation slide 103 is installed on the linear guide rail 102, a servo motor 104 is installed on the translation slide 103, and the servo motor 104 The output end of the aluminum profile base 101 is provided with a drive gear corresponding to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com