New energy automobile maintenance platform

A new energy vehicle and maintenance platform technology, applied in the field of new energy vehicle maintenance platform, can solve the problems of insufficient safety guarantee of the device and lack of personal safety, and achieve the effects of improving firmness, reducing labor, and ensuring personal safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

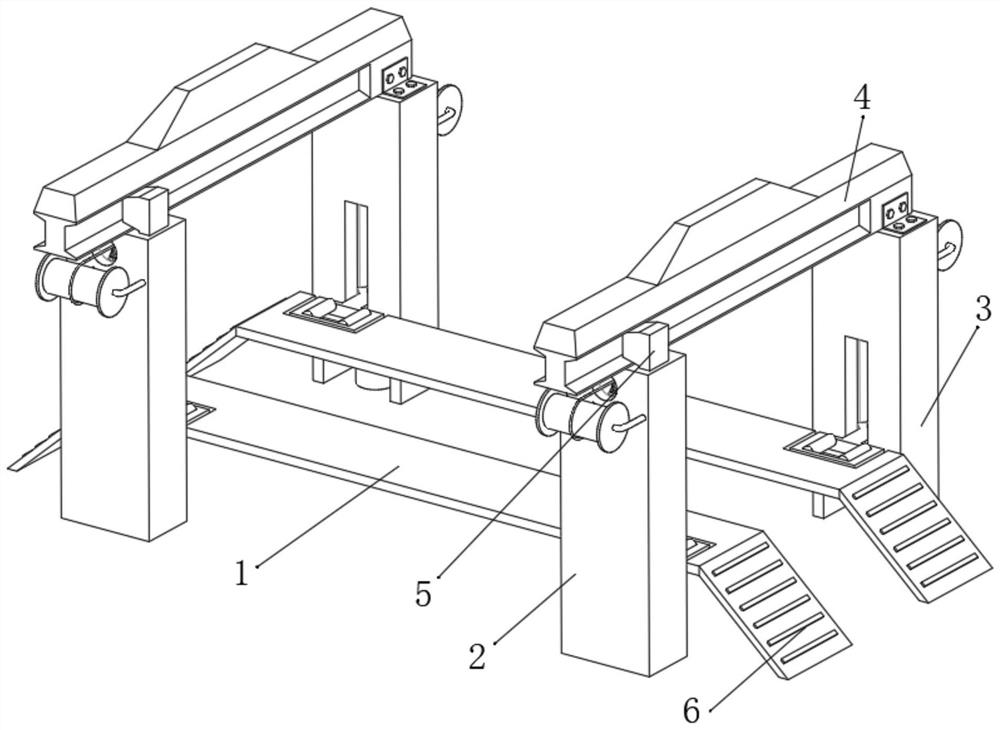

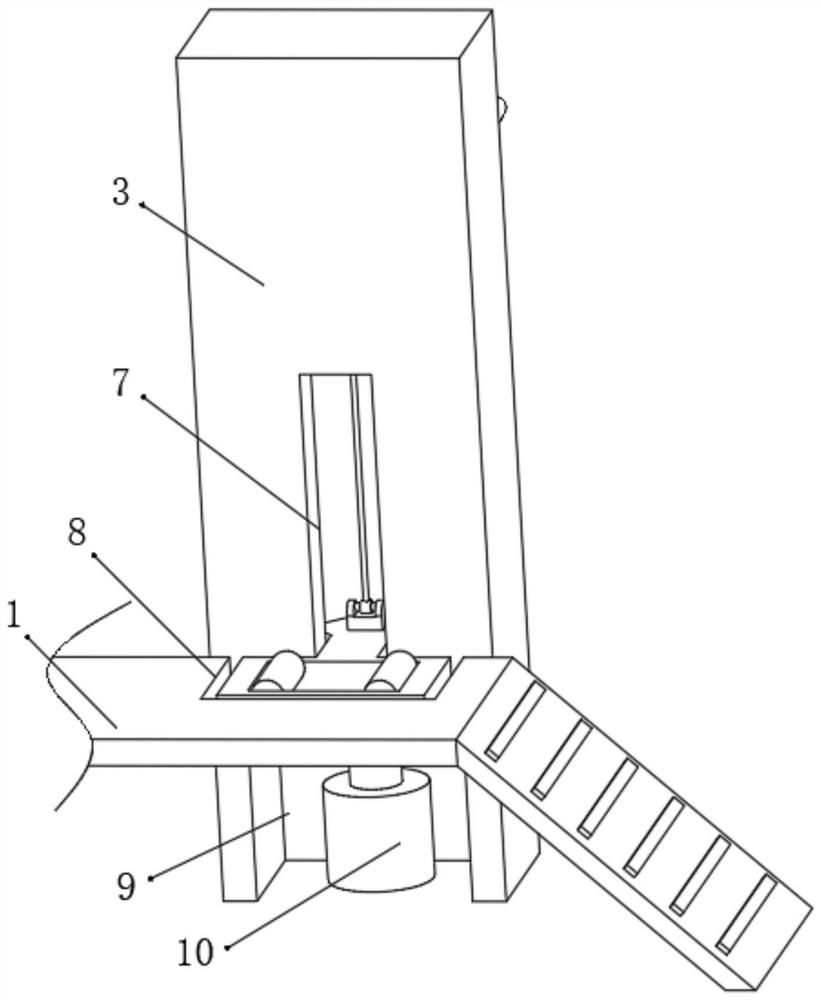

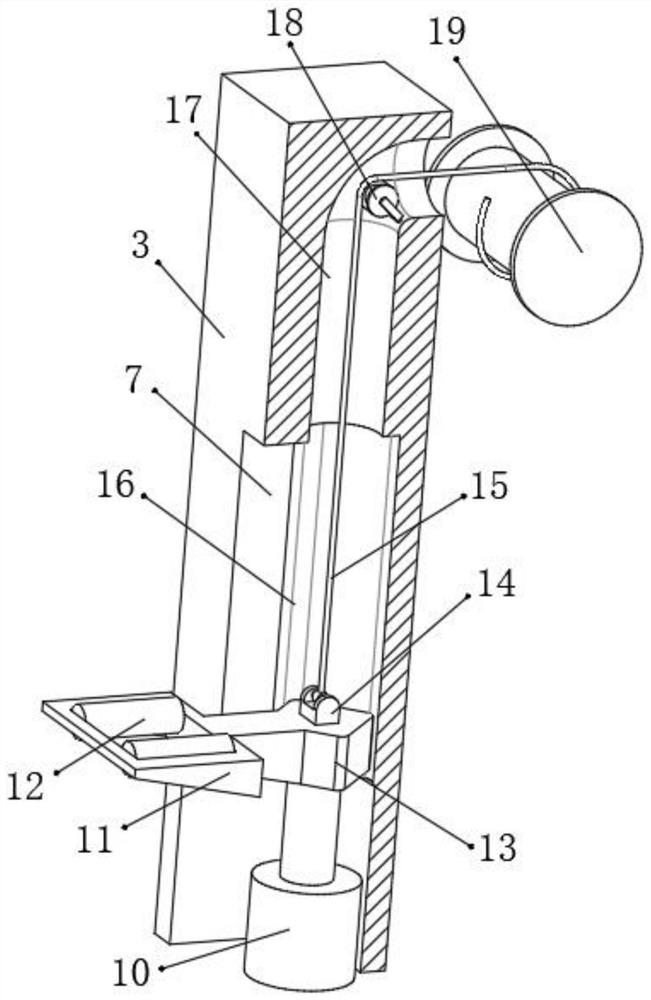

[0031] refer to Figure 1-4 , a new energy vehicle maintenance platform, including a fixed column 3, a beam 4, a sliding column 2 and a support plate 1, the fixed column 3 and the beam 4 are welded, the internal structure of the fixed column 3 and the sliding column 2 is the same as the external structure, The inside of the fixed column 3 is provided with a rope groove 17, an anti-sway groove 16 and a rectangular groove 7, and the rope groove 17 is located at the top of the fixed column 3, and the anti-sway groove 16 is located at the middle of the fixed column 3, and the rectangular groove 7 is located at the anti-sway groove On one side of 16, the inwall of anti-shake groove 16 is slidably connected with load-bearing block 13, and load-bearing block 13 is compatible with anti-shake groove 16, and one side outer wall of load-bearing block 13 is welded with load-bearing plate 11, and the top of load-bearing block 13 is welded There is a connecting block 14, and the inside of t...

Embodiment 2

[0035] refer to Figure 5 , a maintenance platform for new energy vehicles. Compared with Embodiment 1, the position of the outer wall of one side of the fixed column 3 close to the top is connected with an electric telescopic rod 22 by bolts, and one end of the electric telescopic rod 22 is connected to the sliding column 2 connected by bolts.

[0036] Working principle: when in use, move the car to be overhauled to the support plate 1, the inclined plates 6 located on both sides of the support plate 1 facilitate the car to drive to the support plate 1, the front and rear wheels of the car must be located on the load-bearing plate 11, according to For different models, the electric telescopic rod 22 can be used to adjust the distance between the fixed column 3 and the sliding column 2. When the car needs to be opened, the wire winder 19 and the hydraulic rod 10 are opened at the same time, and the load-bearing block 13 is slowly raised. The diamond-shaped design of the anti-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com