Slurry bed reactor catalyst distribution method and system

A reactor and slurry bed technology, applied in the field of reactor catalyst distribution, can solve the problems of unstable operation of the device, low product yield, difficult temperature control, etc., and achieves low equipment investment, simple process structure, and avoidance of valve wear and tear. The effect of endoleak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

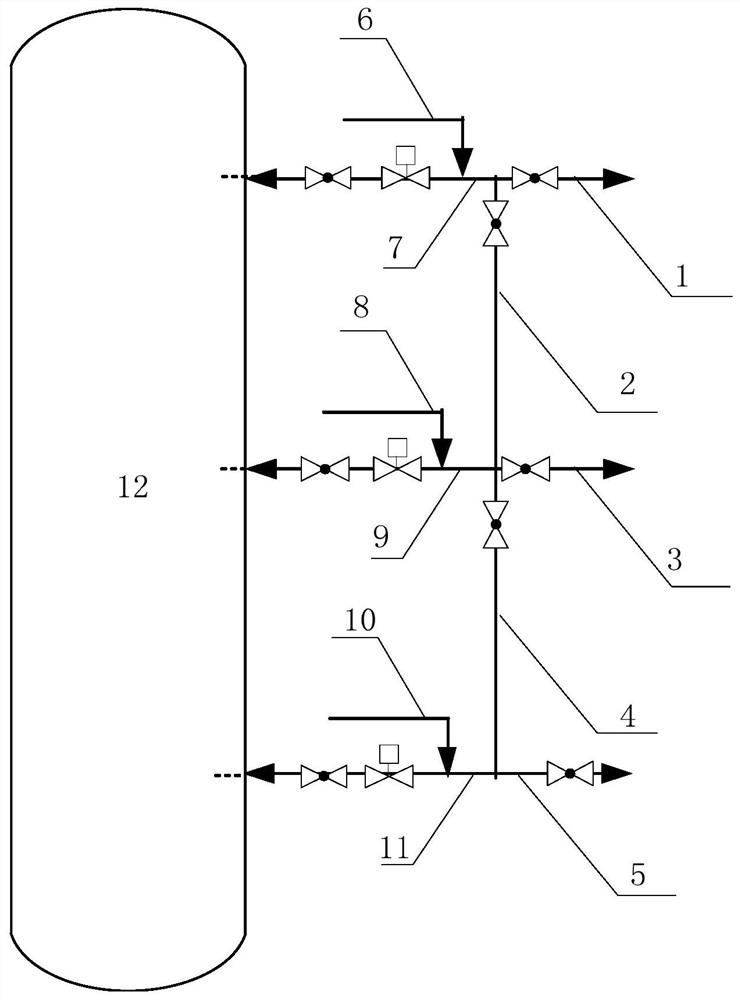

[0041] According to a preferred embodiment of the present invention, the method also includes, when the slurry bed reactor is fed, the catalysts are independently fed from the upper section, the middle section and the lower section of the slurry bed reactor. Catalyst lines are introduced into the slurry bed reactors respectively. In this preferred embodiment, the temperature of the lower stage is avoided from rising too fast when the catalyst is fed, which is beneficial to control the temperature in the reactor to be more stable.

[0042] According to the present invention, preferably, when the slurry bed reactor is discharging the catalyst, the catalysts are independently drawn from the catalyst pipelines arranged in the upper section, the middle section and the lower section of the slurry bed reactor. The slurry bed reactor.

[0043] According to the present invention, preferably, after the feeding or unloading of the slurry bed reactor is completed, the catalyst pipeline i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com