A kind of high-strength al-zn-mg-cu aluminum alloy and preparation method thereof

An aluminum alloy, high-strength technology, applied in the field of aluminum alloy, can solve the problems of low tensile strength and fatigue resistance, achieve the effects of improving mechanical properties, increasing service life and temperature, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

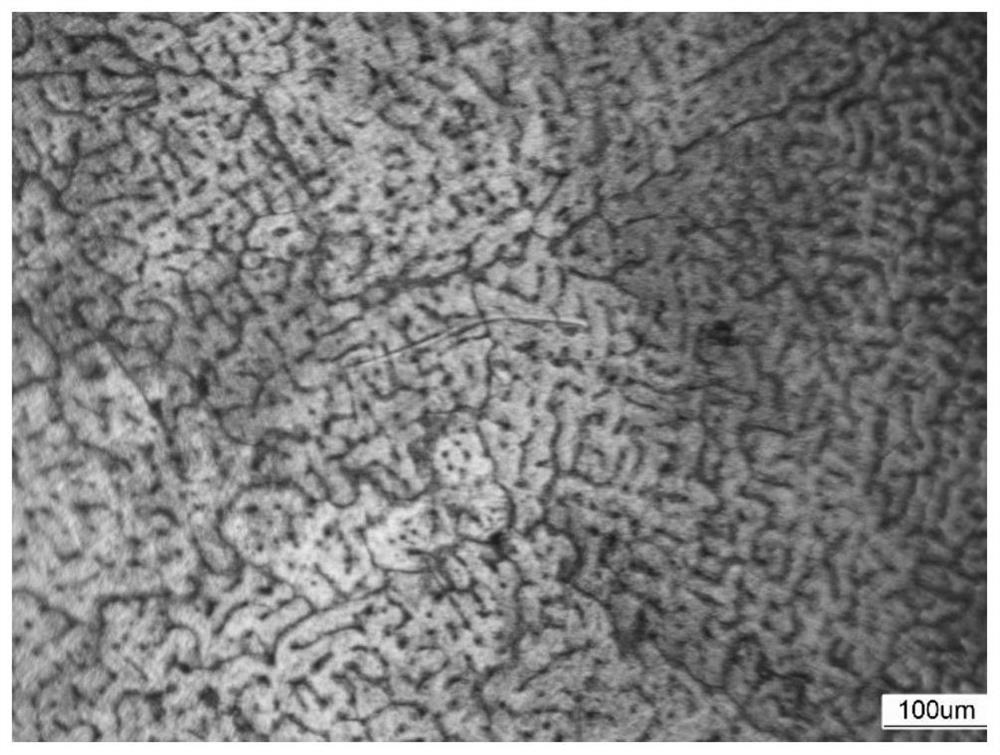

Image

Examples

Embodiment 1

[0038] A high strength Al-Zn-Mg-Cu aluminum alloy, alloy composition is 2.3% by weight of the copper content, 2.4% mg content, zinc content 6.2%, Si: ≤ 0.5%, Fe: ≤ 0.5%, SC The content was 0.26%, the Zr content was 0.13%, SC: Zr = 2: 1, Y: 0.3%, the margin is aluminum.

[0039] The specific preparation method, the steps are:

[0040] A, smelting: high-pure aluminum, high-pure magnesium, aluminum copper, aluminum, intermediate alloy, aluminum zinc intermediate alloy, aluminum zirconia alloy is raw material. Among them, the purity of high pure aluminum is 99.9%, the purity of industrial pure magnesium is 99.9%, and the content of copper in the intermediate alloy in the aluminum copper is 50.0%, and the content of the aluminum mid-alloy is 2.0%, zirconium in aluminum zirconium alloy. The content is 40.0%, and the content of zinc in the intermediate alloy in aluminum zinc is 20.0%, and the content of 钇 in the middle alloy in the aluminum is 10%, and the raw material is weighed accordi...

Embodiment 2

[0049] A high strength Al-Zn-Mg-Cu aluminum alloy, alloy composition is 2.3% by weight of the copper content, 2.4% magnesium content, 6.2% zinc content, 0.3% SC content, and Zr content of 0.1%, SC: Zr = 3: 1, Y: 0.3%, the margin is pure aluminum.

[0050] The specific preparation method, the steps are:

[0051] A, smelting: high-pure aluminum, high-pure magnesium, aluminum copper, aluminum, intermediate alloy, aluminum zinc intermediate alloy, aluminum zirconia alloy is raw material. Among them, the purity of high pure aluminum is 99.9%, the purity of industrial pure magnesium is 99.9%, and the content of copper in the intermediate alloy in the aluminum copper is 50.0%, and the content of the aluminum mid-alloy is 2.0%, zirconium in aluminum zirconium alloy. The content is 40.0%, and the content of zinc in the intermediate alloy in aluminum zinc is 20.0%, and the content of 钇 in the middle alloy in the aluminum is 10%, and the raw material is weighed according to the ratio, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com