A control system for energy balance of aluminum electrolyzer

An aluminum electrolytic cell and control system technology, applied in the field of electrolytic aluminum, can solve problems such as insufficient accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

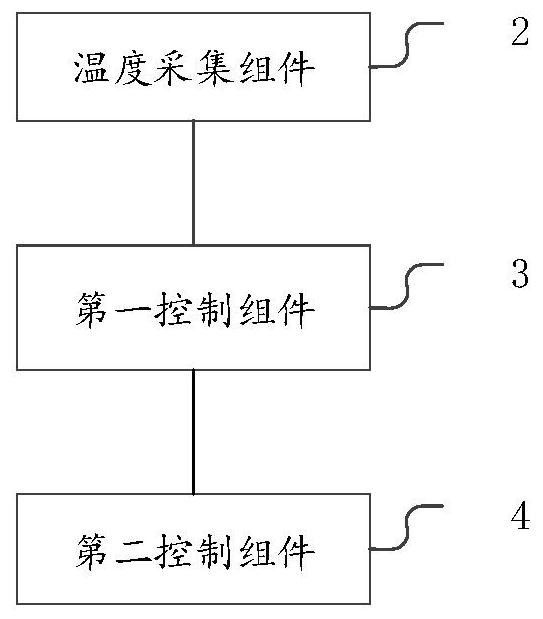

Method used

Image

Examples

Embodiment 1

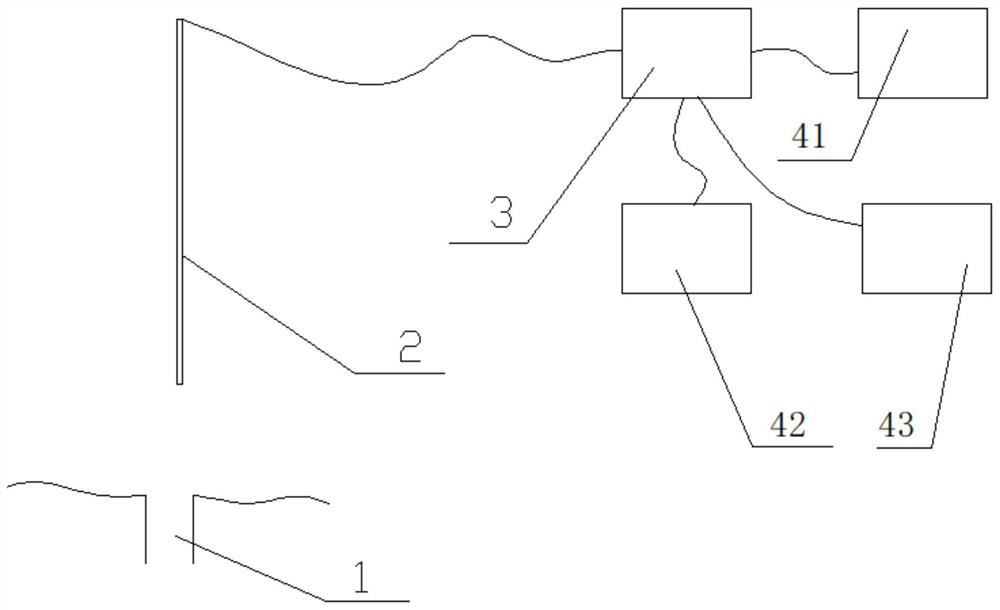

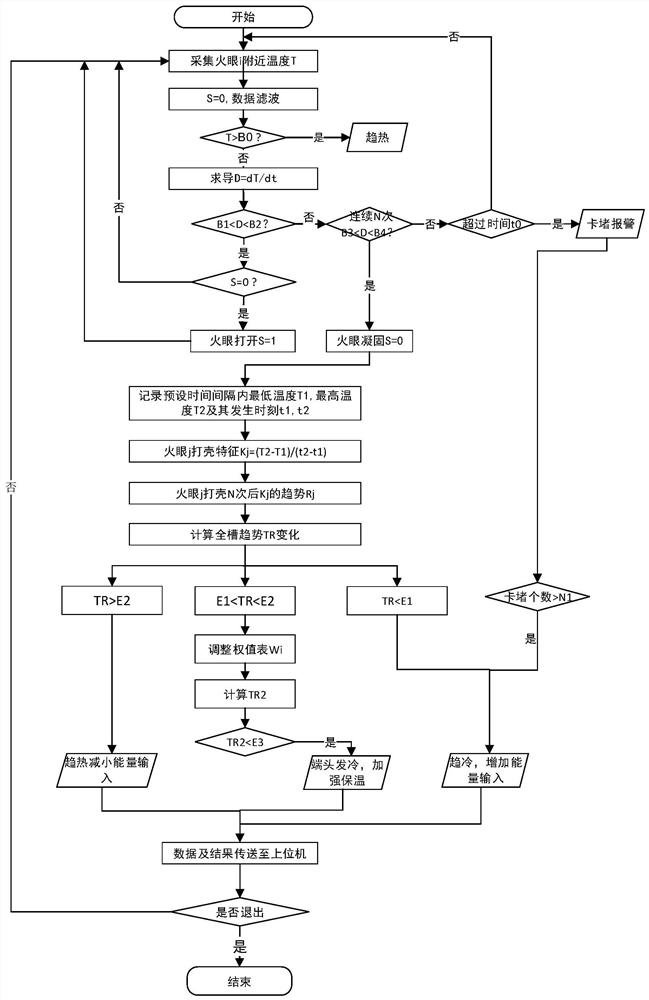

[0096] In this example, a temperature sensor is installed above 6 fire holes on a 300KA electrolytic cell. The temperature sensor is fixed on the outer wall of the shell casing. The line is connected to the controller at the flue end of the tank, and the controller is connected to the upper computer in the work area. The controller starts to collect the temperature of the sensor in real time from Huoyan 1, the sampling period is 1 second, and the shelling flag S=0; the collected temperature fluctuates around 140°C, and after filtering by the moving average, the characteristic value D is between -0.5 and 0.5 fluctuation. When the shelling hammer hits the shell surface of the fire eye and opens the fire eye, the controller collects a sudden change in temperature from 140°C to 150°C, calculates D=10, D is between the set values [8,20], and the shelling mark S = 1; start recording the lowest temperature T1 = 140°C, t 1 = 1s, after 5 seconds it rises to the highest temperature ...

Embodiment 2

[0098] In this example, a temperature sensor is installed on the upper side of 6 fire holes on a 350KA electrolytic cell. The temperature sensor is fixed on the outer wall of the feeding pipe. It is connected to the controller at the flue end of the tank, and the controller is connected with the tank control machine. The controller starts to collect the temperature of the sensor in real time from Huoyan 1, the sampling period is 1 second, and the shelling flag S=0; the collected temperature fluctuates around 150°C, and after filtering by the moving average, the characteristic value D is between -1.0 and 1.0 fluctuation. When the shelling hammer hits the shell surface of the fire eye and opens the fire eye, the controller collects that the temperature changes from 150°C to 165°C, D=15, D is between the set value [10,20], and the shelling flag S=1 ;Start to record the lowest temperature T1=150°C, rise to the highest temperature 185°C after 5 seconds and then start to drop, reco...

Embodiment 3

[0100] In this example, an alarm light is installed on a 400KA electrolytic cell, and temperature sensors are installed above the six fire holes. The controller at the flue end of the electrolytic cell, the controller is connected to the upper computer, the tank control machine, and the alarm light on the tank at the same time. The controller starts to collect the temperature of the sensor in real time from Huoyan 1, the sampling period is 1 second, and the shelling flag S=0; the collected temperature fluctuates around 150°C, and after filtering by the moving average, the characteristic value D is between -1.0 and 1.0 fluctuation. When the shelling hammer hits the shell surface of the fire hole and opens the fire hole, affected by the adjacent fire hole, the temperature collected by the controller changes from 150°C to 153°C, and the characteristic value D=3, which is located at the preset set value [10,20] In addition, the shelling flag S=0; when the shelling flag S is 0 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com