Gas mass flow controller and fault self-checking method

A gas mass flow, fault self-checking technology, applied in flow control, flow control using electrical devices, non-electric variable control, etc., can solve problems such as affecting product quality, affecting economic benefits, and difficulty in detection, and reducing equipment downtime. and maintenance time, improve economic efficiency, and reduce the effect of detection difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

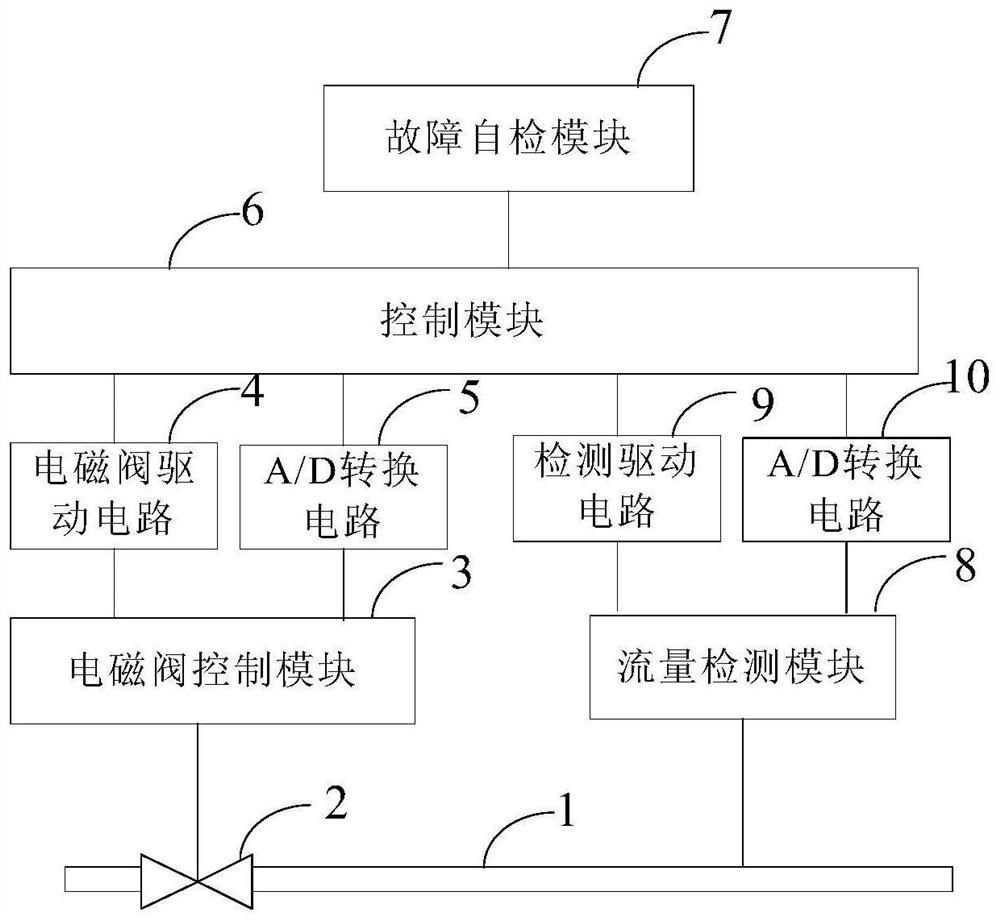

[0041] see figure 1 , the gas mass flow controller (hereinafter referred to as MFC) provided by this embodiment includes a solenoid valve 2, a solenoid valve control module 3, a solenoid valve drive circuit 4, a control module 6, a fault self-check module 7, a flow detection module 8 and Detection drive circuit 9. Wherein, the solenoid valve 2 is arranged on the controlled pipeline 1; the solenoid valve control module 3 is used to adjust the opening degree of the solenoid valve 2, so as to adjust the flow of gas flowing through the solenoid valve 2. The solenoid valve driving circuit 4 is used to provide driving electric energy, that is, a driving voltage to the solenoid valve control module 3 , so as to adjust the opening degree of the solenoid valve 2 .

[0042] The flow detection module 8 is used to detect the flow of gas flowing through the above-mentioned electromagnetic valve 2, and send out a flow analog signal, which is converted into a digital signal that can be proc...

no. 2 example

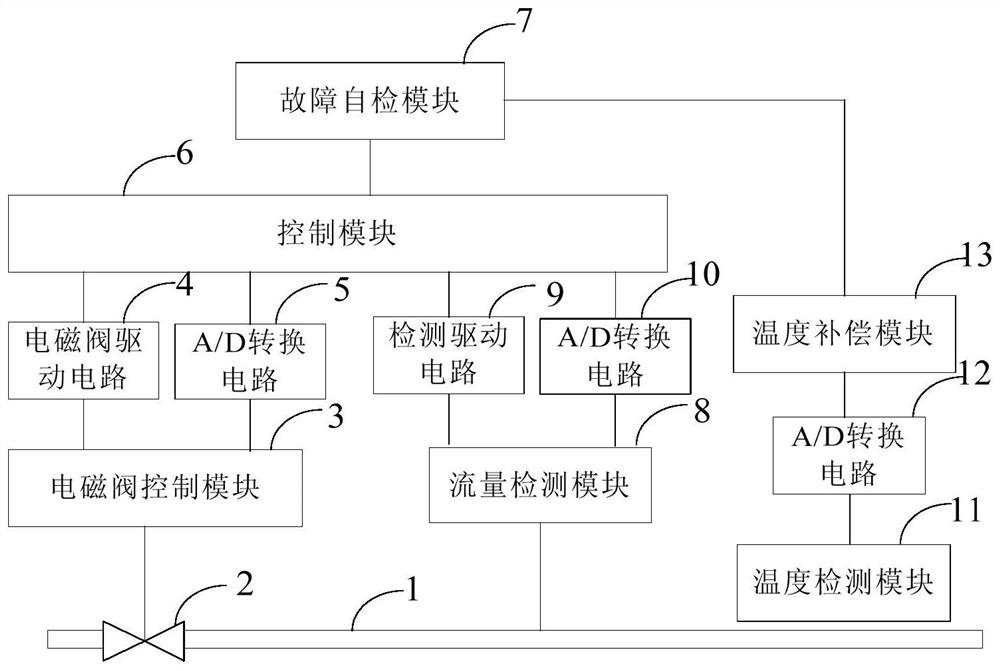

[0049] see image 3 , the gas mass flow controller provided in this embodiment is an improvement made on the basis of the above-mentioned first embodiment. Specifically, since the gas is greatly affected by temperature, under the same gas flow setting value, If the fluid temperature is different, the opening value of the solenoid valve 2 will be slightly different. In order to eliminate the influence of temperature, it is necessary to perform temperature compensation on the driving parameter value (driving voltage value or driving current value). For this reason, on the basis of the above-mentioned first embodiment, the gas mass flow controller also includes a temperature detection module 11 and a temperature compensation module 13, wherein the temperature detection module 11 is used to detect the current opening degree in the controlled pipeline 1 The current fluid temperature value corresponding to the value is sent to the temperature compensation module 13 after the A / D con...

no. 3 example

[0061] see Figure 4 , this embodiment provides a fault self-diagnosis method, which is applied to the gas mass flow controller provided in the first embodiment above, and the gas mass flow controller includes a solenoid valve 2, a solenoid valve control module 3 and a solenoid valve drive circuit 4 . The fault self-diagnosis method includes the following steps:

[0062] S1. According to the preset flow setting value, control the solenoid valve control module to adjust the opening of the solenoid valve to the opening value corresponding to the flow setting value;

[0063] S2. Receive the current driving parameter value of the solenoid valve corresponding to the opening value fed back by the solenoid valve control module;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com