Digital twin-driven offshore oil underwater production system fault prediction method and system

A production system and offshore oil technology, applied in the field of fault prediction of offshore oil underwater production systems, can solve problems such as failure to reflect the life information of fault conditions, incomplete maintenance information, etc., to achieve effective prediction and continuous update, and accurate remaining life analysis. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

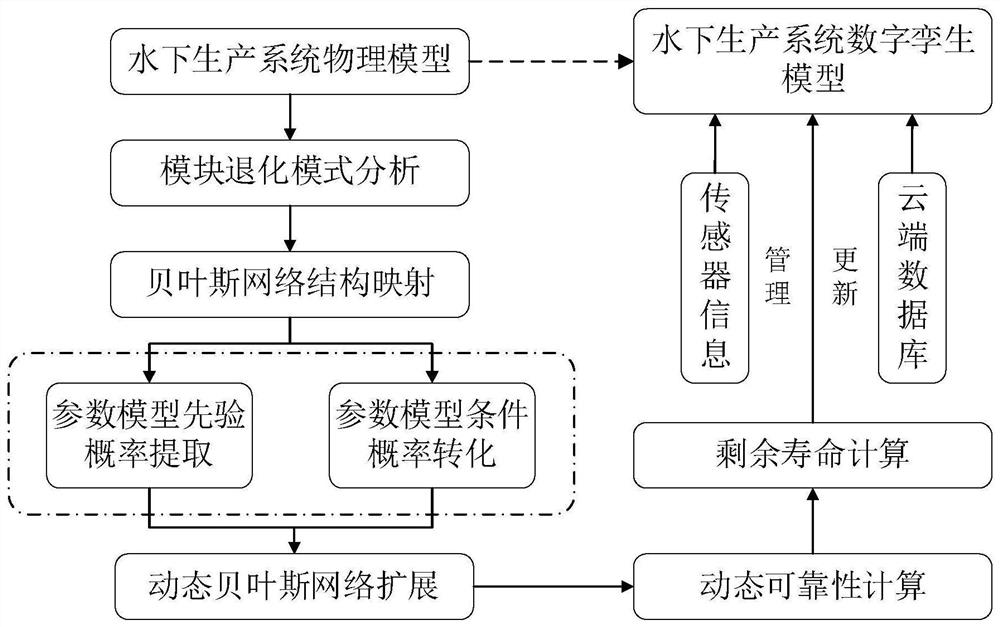

[0030] Such as figure 1 As shown, a digital twin-driven offshore oil production system failure prediction method includes five major steps:

[0031] S1: Determine the degradation mode of each module. The underwater production system is divided into electronic control module, hydraulic module and mechanical part for degradation analysis, and the state monitoring data in the operation of the underwater production system is obtained for parameter estimation, and combined with the experience of field experts, the parameters in each degradation model are different. Determine the analysis and correction of probability distributions.

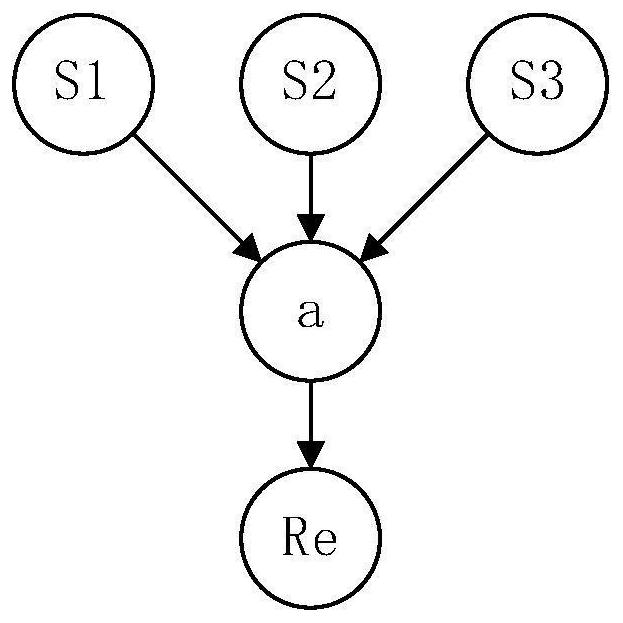

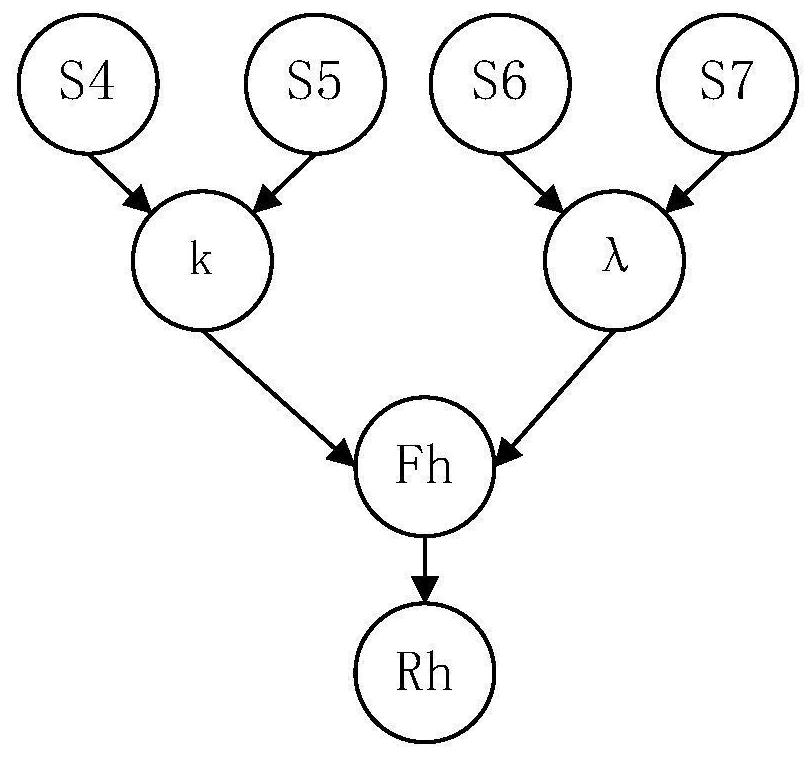

[0032] S101: Determine the degradation models of the electronic control module, the hydraulic module and the mechanical part.

[0033](1) For the electronic control module in the underwater production system, its reliability degradation model is an exponential degradation model:

[0034] Re=e -at (1)

[0035] Among them, Re is the reliability of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com