Material and personnel management system based on three-dimensional code

A personnel management and three-dimensional code technology, applied in logistics, resources, data processing applications, etc., can solve the problems of real-time supervision, comprehensive supervision, insufficient awareness of safety hazards, lack of material risk management and other problems in limited space, and achieve increased Effects of online safety training, enhancing safety awareness, and reducing human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

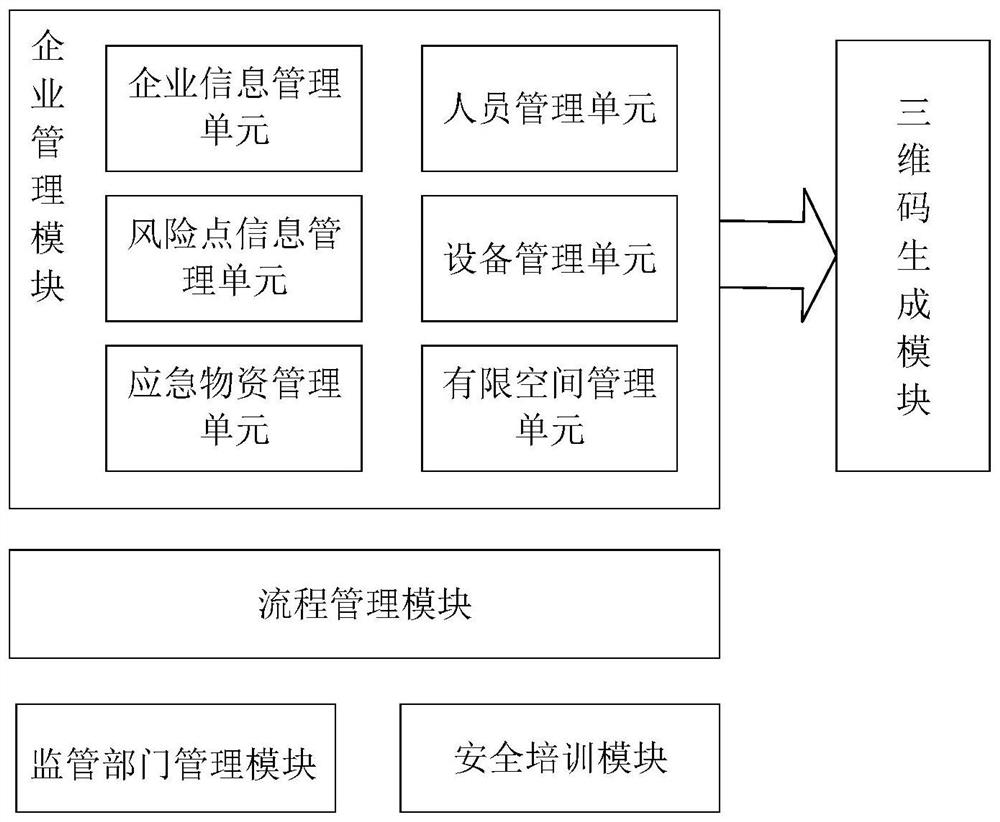

[0028] See figure 1 , A three-dimensional code-based material and personnel management system, including: enterprise management module, process management module and three-dimensional code generation module;

[0029] The enterprise management module includes a personnel management unit, an equipment management unit, and a limited space management unit; the personnel management unit is used to manage personnel information and configure corresponding system resource access permissions. The personnel information includes department, name, photo, gender, and age. , Job title, mobile phone number, status; personnel with different permissions can perform operations such as job permit application and risk point content editing under the corresponding permissions. For foreign workers, they can apply for temporary personnel three-dimensional codes in the back-end management system. After time, the three-dimensional code of the outsider becomes invalid.

[0030] The equipment management unit...

Embodiment 2

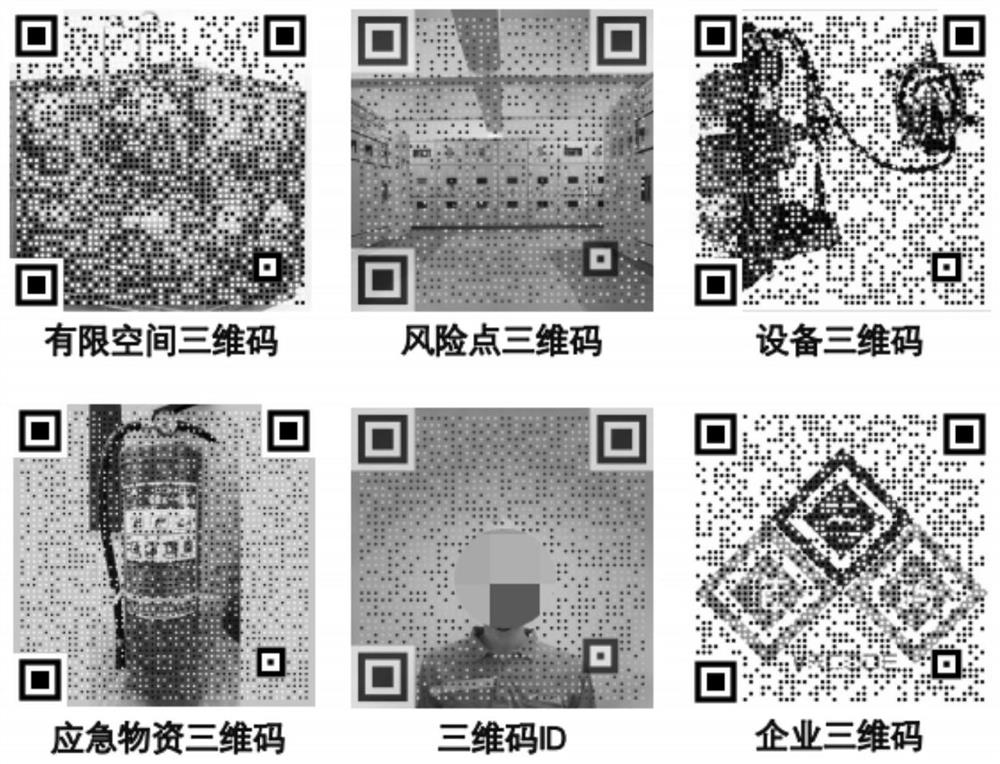

[0036] Further, the enterprise management module further includes a risk point information management unit for managing risk point information and setting up a question bank based on the information of each risk point; the risk point information is input to the three-dimensional code generation module, and the three-dimensional code generation The module generates a risk point 3D code for each risk point, scans the risk point 3D code to get the risk point information or chooses to jump to the online answering training of the risk point. The risk point information is filled in and uploaded by the relevant person in charge of the enterprise, including its own enterprise department, person in charge, name, picture, risk level, location, safety signs, accident type, danger overview, control measures, notice board, and emergency response.

[0037] The management of risk points is the top priority of safety management. The improvement of this embodiment lies in the realization of unifie...

Embodiment 3

[0039] Further, the enterprise management module further includes an emergency material management unit for managing basic information, spot inspection records, maintenance records, and warehouse entry and exit records of emergency materials; the emergency materials are input to the three-dimensional code generation module, and the three-dimensional code The generation module generates a three-dimensional code for each emergency material; when the emergency material is out of the warehouse, warehousing, spot inspection, and maintenance, the operator scans the three-dimensional code of the emergency material and uploads the corresponding record. The emergency information includes fill-in and upload by the relevant person in charge of the company, including the company's department, person in charge, name, picture, specification, production date, manufacturer, storage location, inventory, safety stock, instructions for use, and status.

[0040] The improvement of this embodiment lie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com