Process for improving freshness of flat breads involving combination of maltogenic alpha amylase variants

A technology of amylase and maltose, applied in biochemical equipment and methods, glycosylation enzymes, baking mixtures, etc., can solve problems such as fast baking time that is not suitable for flat bread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0111] Pita Bread - Evaluated after 2 days storage

[0112] Pita bread is made with a straight dough recipe.

[0113] The flour was wheat flour of medium baking quality.

[0114] Added enzymes:

[0115] First maltose alpha-amylase (SEQ ID NO: 1 with substitutions D261G, T288P, and F188L) in an amount of 1 mg enzyme protein / kg flour.

[0116] A second maltose alpha-amylase (SEQ ID NO: 1 with substitutions D261G, T288P, F194Y and N375S) in an amount of 1.6 mg enzyme protein / kg flour.

[0117]

[0118] Store flat bread at room temperature in an airtight plastic bag.

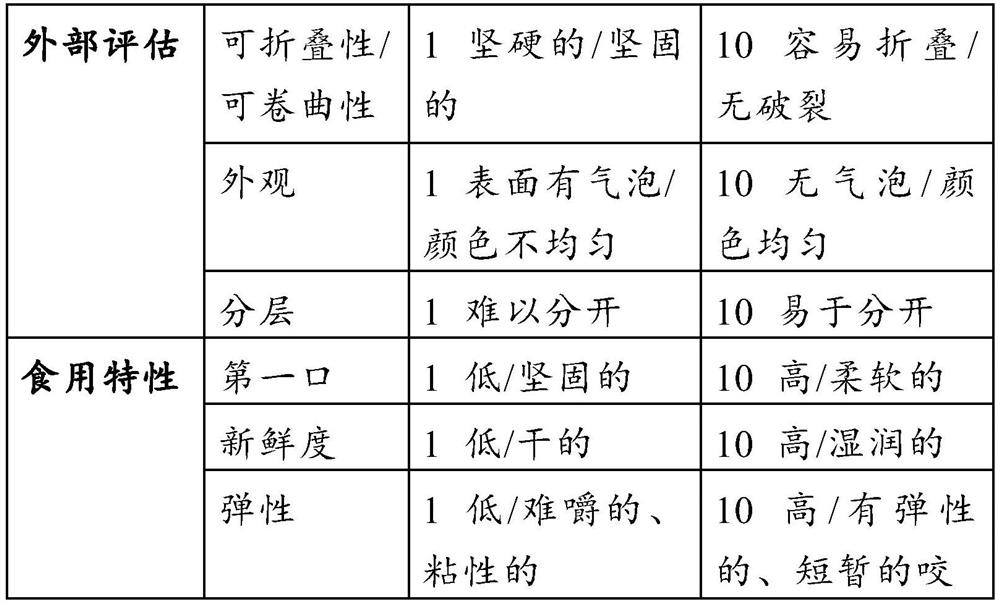

[0119] Evaluate the results as follows:

[0120] Table 1:

[0121]

[0122] Two different pita breads were presented to a trained panel of judges and asked to rate them, with 1 being the lowest performance and 10 being the best performance. The pita bread was evaluated after 2 days of storage.

[0123] result:

[0124] External features:

[0125] Table 2:

[0126] pita bread feature C...

example 2

[0133] Pita Bread - Evaluated after 7 days storage

[0134] Pita bread was made on an industrial scale using a straightforward dough recipe (75 kg wheat flour, 2.3 kg fresh yeast, 0.9 kg salt, 3 kg sugar, 36 kg water, 0.2 kg sorbic acid).

[0135] Wheat flour is untreated flour.

[0136] Added enzymes:

[0137] First maltose alpha-amylase (SEQ ID No: 1 with substitutions D261G, T288P, and F188L) in an amount of 4 mg enzyme protein / kg flour.

[0138] Second maltose alpha-amylase (SEQ ID NO: 1 with substitutions D261G, T288P, F194Y and N375S) in an amount of 0.4 mg enzyme protein / kg flour.

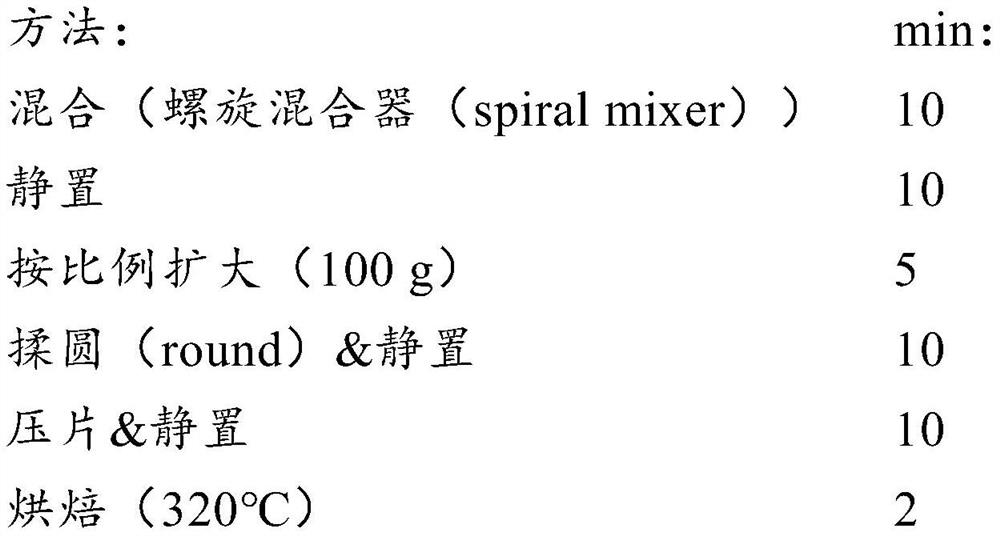

[0139] Table 4 - Methods:

[0140]

[0141] The flatbreads were evaluated by a trained panel of tasters after 7 days and the results were as follows:

[0142] table 5:

[0143] pita bread feature Control (no enzyme) Enzyme blend according to example 2 Exterior 5 9 Foldability / Rollability 5 9 softness 5 8 chewiness 5 8 Overall edible pr...

example 3

[0147] Lebanese Flat Bread - Evaluate after 3 days storage

[0148] Make Lebanese flat bread as follows:

[0149] Table 6 - Recipe for Lebanese Bread

[0150] Element Quantity, %(w / w) 750 type white flour 100 fresh yeast 2 Salt 0.25 sugar 3 water 52

[0151] Added enzymes:

[0152] Mixture A: a first maltose alpha-amylase (SEQ ID No: 1 with substitutions D261G, T288P, and F188L), in an amount of 4 mg enzyme protein / kg flour; and a second maltose alpha-amylase (with substitutions D261G, SEQ ID NO: 1) of T288P, F194Y and N375S, in the amount of 0.4 mg enzyme protein / kg flour

[0153] Mixture B: Maltose alpha-amylase (SEQ ID NO: 1 with substitutions D261G, T288P, and F188L) in an amount of 4.4 mg enzyme protein / kg flour

[0154] Mixture C: Maltose alpha-amylase (SEQ ID NO: 1 with substitutions D261G, T288P, F194Y and N375S) in an amount of 4.4 mg enzyme protein / kg flour

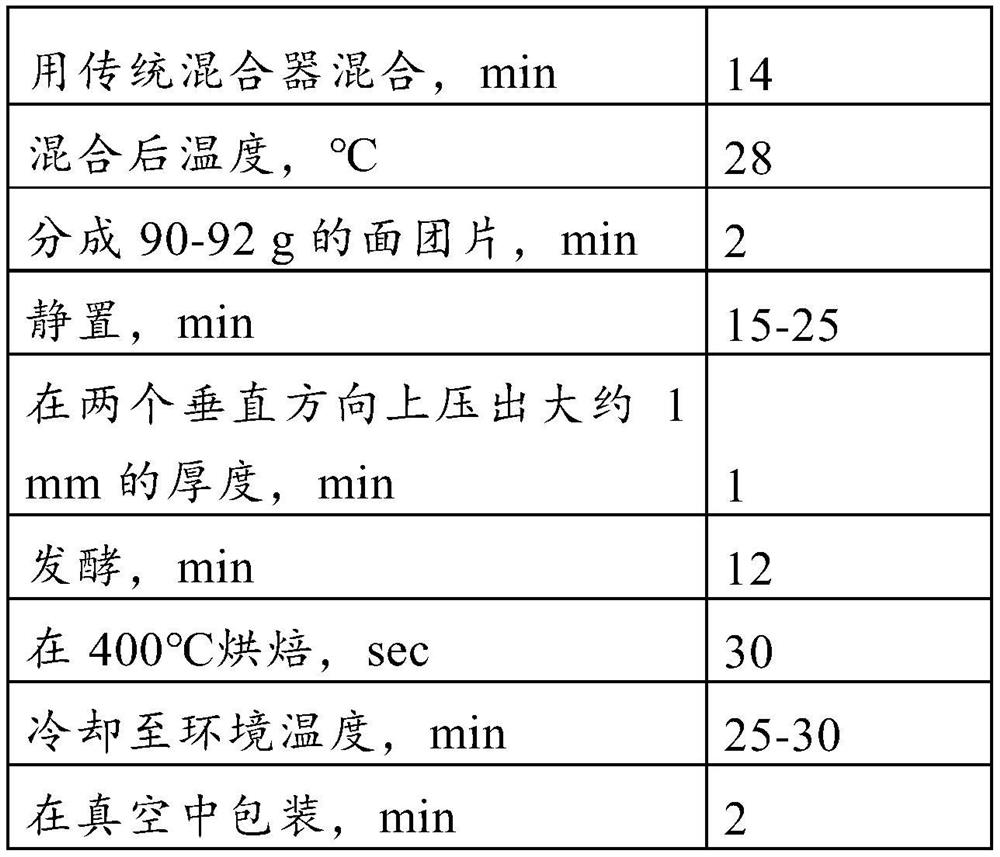

[0155] program:

[0156] Combine all ingredients.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com