Cut stem making system capable of increasing proportion of filamentous cut stems

A technology of cut stem and proportion, applied in the field of cut stem making system, can solve the problems such as the inability to effectively reduce the consumption of tobacco leaves and the low utilization range of cut stems, and achieve the effects of improving the effective utilization rate, reducing the crushing and improving the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

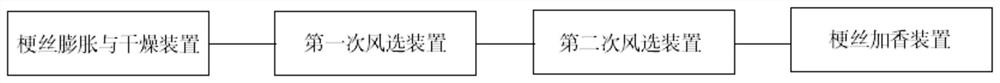

[0021] This technical solution is based on the use of the existing cut stem production line, by adding a second winnowing device behind the winnowing device of the current production line, to realize the separation of normal filamentous cut stems and thin sliced cut stems, and simultaneously The stems that have not been separated in the primary winnowing device are separated again to increase the proportion of filamentous cut stems, thereby improving the effective utilization rate of cut stems and reducing the consumption of tobacco leaves.

[0022] Such as figure 1 As shown, the present application provides a system for making cut s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com