Ten-ton liquid-phase material filling shell capable of conducting automatic turnover through mass center position adjustment

An automatic flipping and casing technology, which is applied in fire rescue and other directions, can solve problems such as failure of thin-walled casings, insufficient casing strength, and inability to accurately control the speed of the casing flipping process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

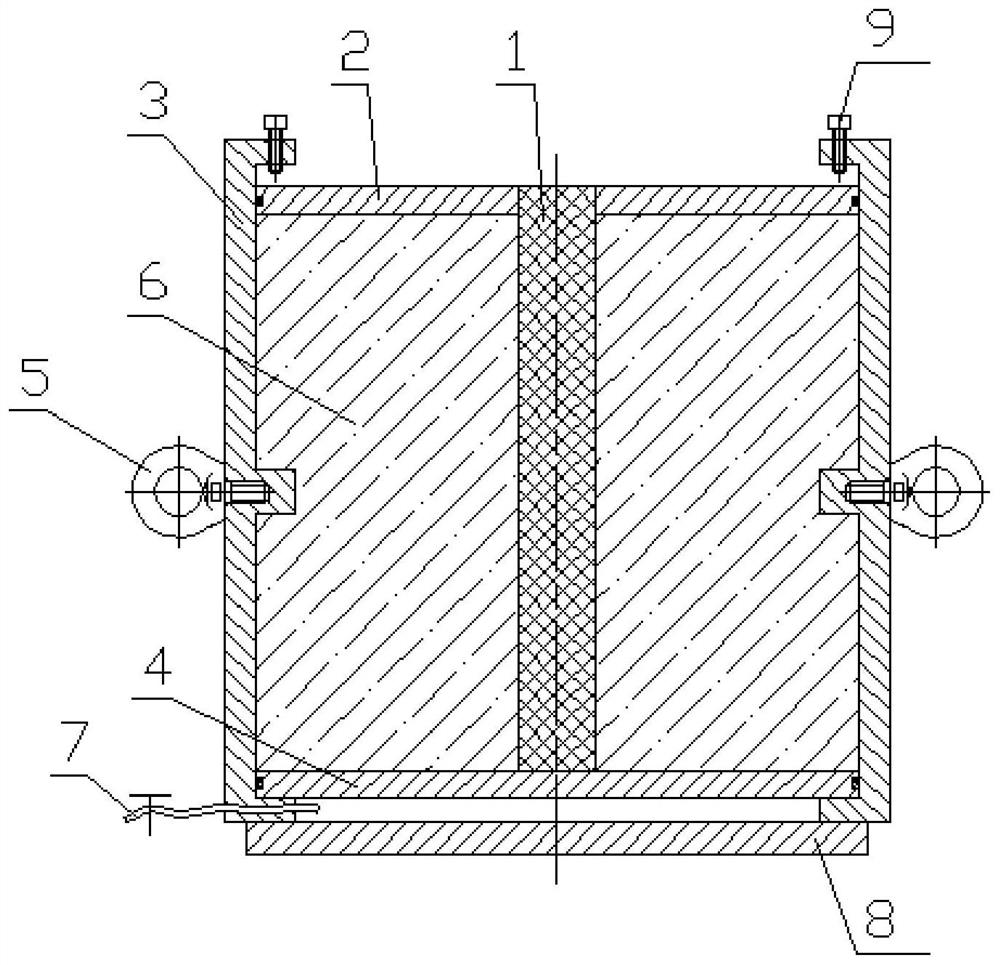

[0066] Such as figure 1 As shown, this embodiment provides a ten-ton liquid-phase material filling shell that is automatically turned over by adjusting the position of the center of mass, including a throwing pipe 1, an upper end cover 2, a lower end cover 4, and a liquid 6, which is characterized in that it also includes a shell Body 3, lifting ring 5, inflation tube 7, temporary baffle 8, set screw 9;

[0067] The throwing pipe 1 is a first cylinder, the first cylinder of the throwing pipe 1 is a body of revolution, the upper end surface of the first cylinder of the throwing pipe 1 is the first upper end circular plane, and the side surface of the first cylinder of the throwing pipe 1 is The first outer cylindrical surface, the lower end surface of the first cylinder of the throwing pipe 1 is the first lower end circular plane;

[0068] The axis of the rotating body of the throwing pipe 1 is perpendicular to the horizontal plane, and the inside of the throwing pipe 1 is equ...

Embodiment 2

[0137] Such as figure 1 As shown, this embodiment provides a ten-ton liquid-phase material filling shell that is automatically turned over by adjusting the position of the center of mass, including a throwing pipe 1, an upper end cover 2, a lower end cover 4, and a liquid 6, which is characterized in that it also includes a shell Body 3, lifting ring 5, inflation tube 7, temporary baffle 8, set screw 9;

[0138] The throwing pipe 1 is a first cylinder, the first cylinder of the throwing pipe 1 is a body of revolution, the upper end surface of the first cylinder of the throwing pipe 1 is the first upper end circular plane, and the side surface of the first cylinder of the throwing pipe 1 is The first outer cylindrical surface, the lower end surface of the first cylinder of the throwing pipe 1 is the first lower end circular plane;

[0139] The axis of the rotating body of the throwing pipe 1 is perpendicular to the horizontal plane, and the inside of the throwing pipe 1 is equ...

Embodiment 3

[0207] Such as figure 1 As shown, this embodiment provides a ten-ton liquid-phase material filling shell that is automatically turned over by adjusting the position of the center of mass, including a throwing pipe 1, an upper end cover 2, a lower end cover 4, and a liquid 6, which is characterized in that it also includes a shell Body 3, lifting ring 5, inflation tube 7, temporary baffle 8, set screw 9;

[0208] The throwing pipe 1 is a first cylinder, the first cylinder of the throwing pipe 1 is a body of revolution, the upper end surface of the first cylinder of the throwing pipe 1 is the first upper end circular plane, and the side surface of the first cylinder of the throwing pipe 1 is The first outer cylindrical surface, the lower end surface of the first cylinder of the throwing pipe 1 is the first lower end circular plane;

[0209] The axis of the rotating body of the throwing pipe 1 is perpendicular to the horizontal plane, and the inside of the throwing pipe 1 is equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com