Raw material processing, crushing and quantitative mixing reaction device for Chinese patent medicine production

A quantitative mixing and reaction device technology, which is applied in the field of raw material processing, crushing and quantitative mixing reaction devices for the production of Chinese patent medicines, can solve the problems of increasing the difficulty of later-stage pharmaceuticals and affecting the effect of pharmaceuticals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

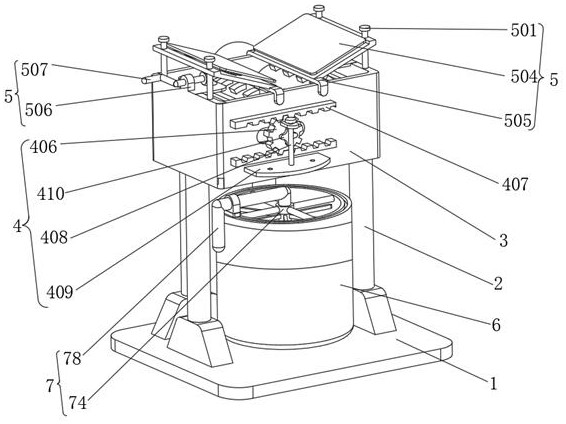

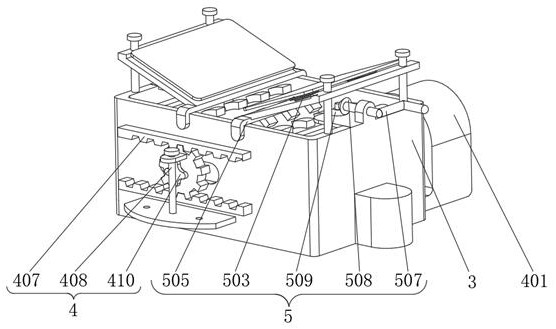

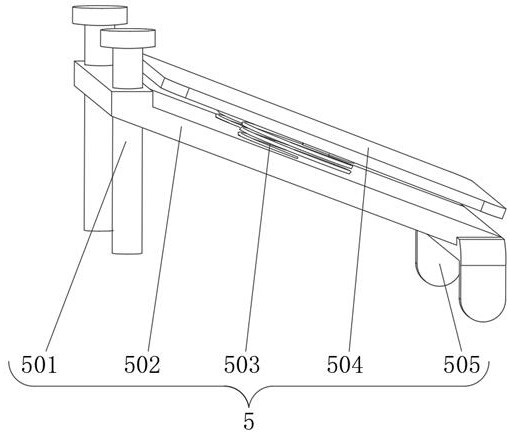

[0031] Example 1, such as Figure 1-9 As shown, the present invention provides a raw material processing crushing quantitative mixing reaction device for the production of Chinese patent medicines, including a backing plate 1 and a crushing device 4, the upper surface of the backing plate 1 is fixedly connected with a support rod 2, and the support rod 2 is far away from the backing plate 1 A baffle 3 is fixedly connected to one end of the baffle 3, a crushing device 4 is provided inside the baffle 3, an adjustment device 5 is provided on the upper end of the baffle 3, and a storage bucket 6 is slidably connected to the upper surface of the backing plate 1, and the storage bucket 6 is round. It is cylindrical, and a stirring device 7 is provided inside the storage bucket 6 .

[0032] Let's talk about its crushing device 4 in detail below, the specific setting and effect of the regulating device 5 and the stirring device 7.

[0033] Such as figure 1 with Figure 5As shown, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com