Notebook hinge flat gasket stringing equipment

A technology of flat gaskets and notebooks, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of waste of labor costs, difficulty in stringing materials, time-consuming and labor-intensive problems, and achieve reduced investment, simple stringing, and efficient stringing high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

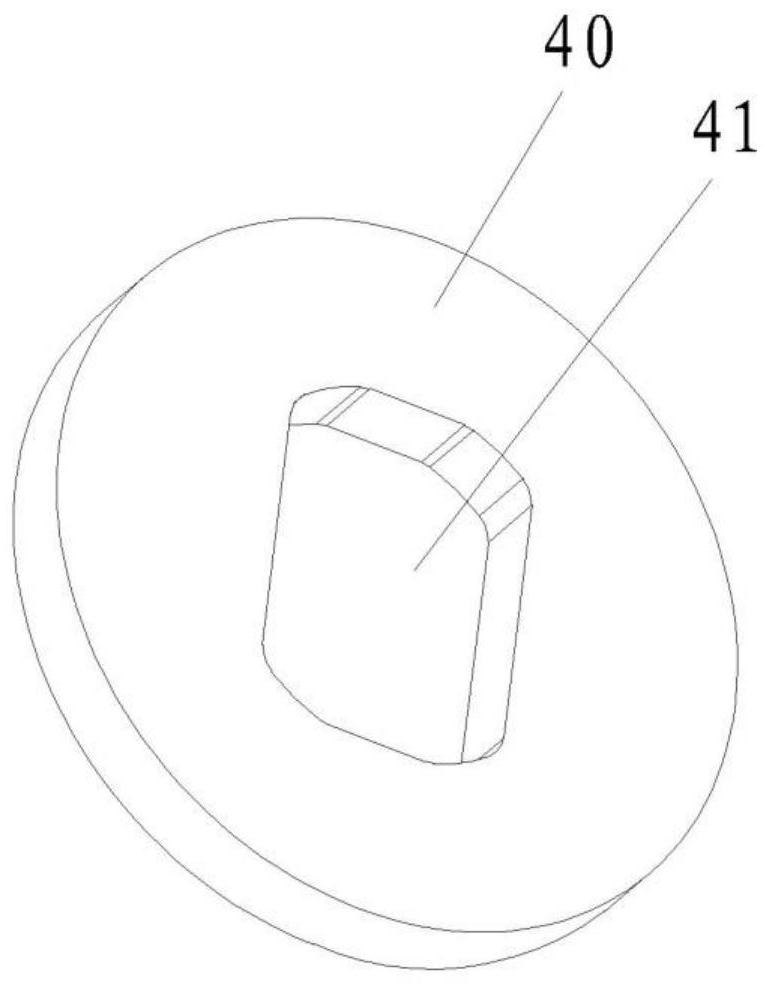

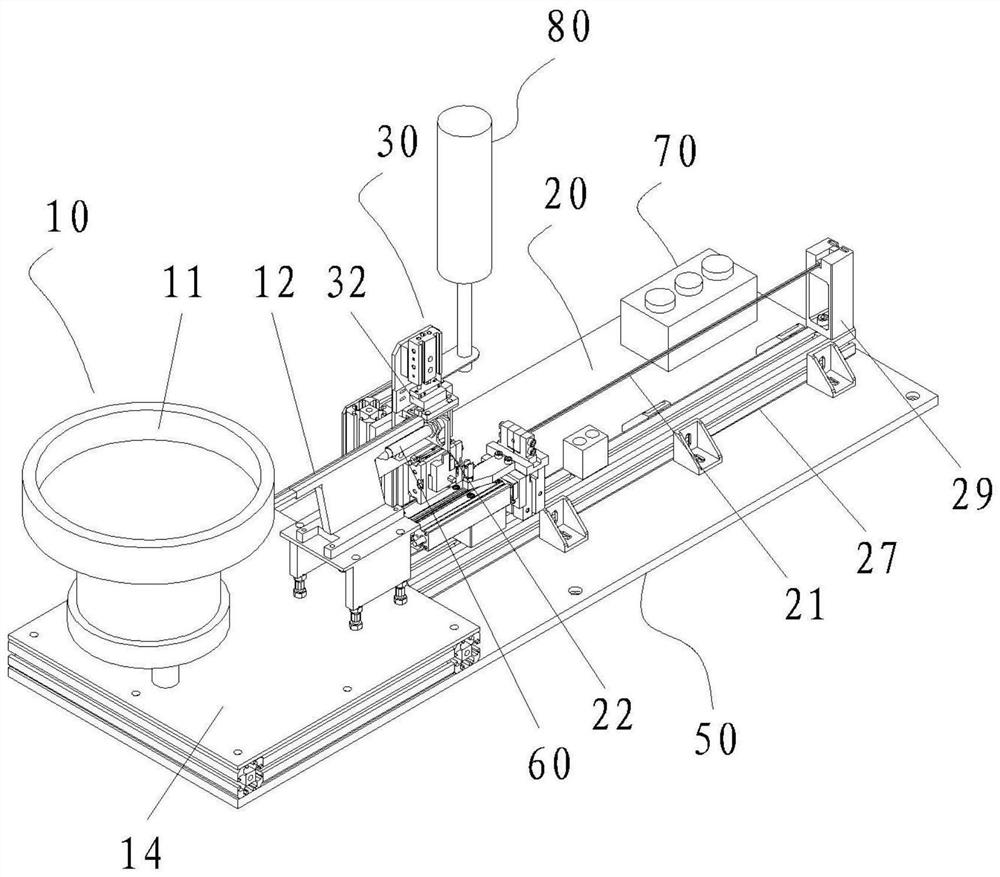

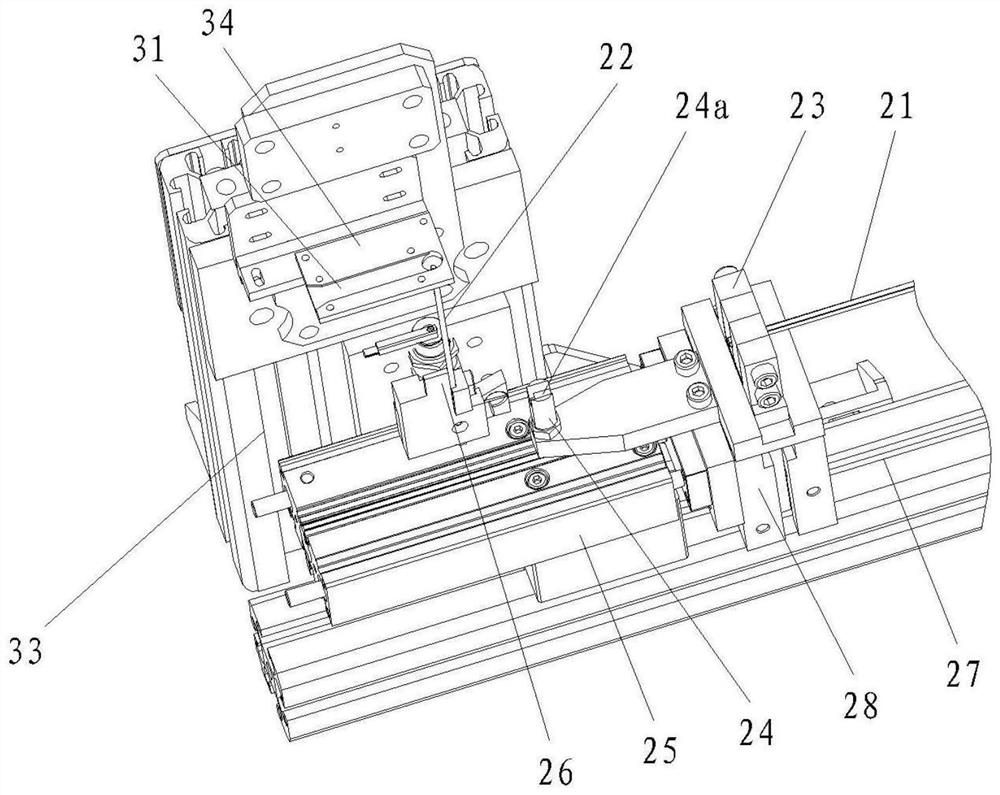

[0022] figure 1 It is a schematic diagram of the flat gasket structure; figure 2 It is a schematic diagram of the overall structure of the present invention; image 3 Schematic representation of the local structure of the present invention figure 1 ; Figure 4 Schematic representation of the local structure of the present invention figure 2 ;

[0023] The notebook hinge flat gasket stringing device of the present embodiment includes a conveying device 10 and a stringing device 20, and the stringing device includes a main stringing rod 21 approximately horizontally arranged, a transition stringing rod 22 approximately vertically disposed and The scraping assembly, the conveying device is used to store the flat gaskets and transport each flat gasket 40 in a single row according to the set posture to the stringing device and string them on the transition stringing rod, and the transition stringing rod can Driven to rotate to a horizontal state to dock with the main materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com