Surface derusting device for processing tubular mechanical parts

A technology of mechanical parts and tubes, which is applied in the field of surface derusting devices for processing tubular mechanical parts, which can solve the problems of surface corrosion of mechanical parts, different lengths of workpieces, poor derusting effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

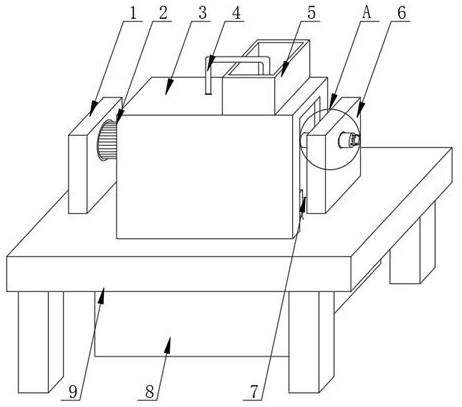

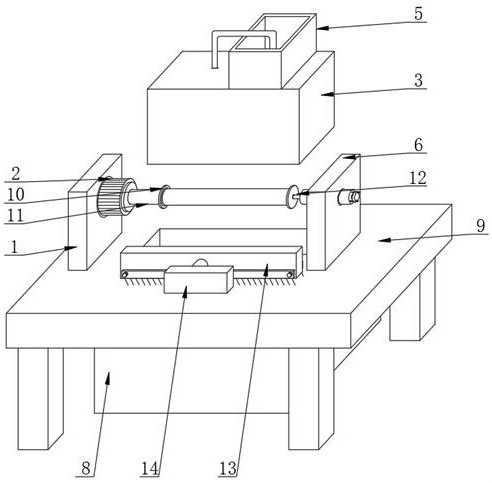

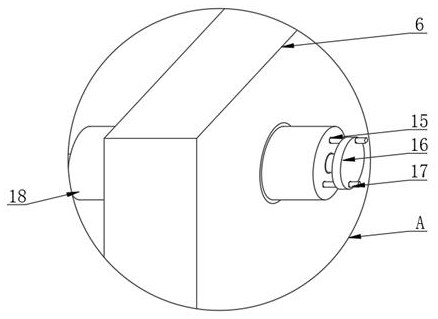

[0027] see Figure 1-7 , in an embodiment of the present invention, a surface derusting device for processing tubular mechanical parts, including a workbench 9, the upper surface of the workbench 9 is respectively equipped with a first fixed plate 1 and a second fixed plate 6 from left to right, The inside of the first fixed plate 1 is equipped with a rotating motor 2, and the driving end of the rotating motor 2 is connected with a rotating shaft 11, and one end of the rotating shaft 11 is fixedly connected with a first limit disc 10, and the inner rotation of the second fixing plate 6 is installed with Rotating column 18, the inside of rotating column 18 is rotated and installed limit rod 16, and the end of limit rod 16 is connected with second limit plate 12, and one side of second limit plate 12 runs through and installs limit column 17, and rotating column One side of 18 is provided with the limit hole 15 that matches mutually with limit post 17, and limit post 17 is cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com