Anti-roll adjustable hydro-pneumatic suspension hydraulic system

A technology of hydraulic system and oil and gas suspension, applied in the field of anti-roll adjustable oil and gas suspension hydraulic system, to achieve the effect of ensuring stability, reasonable structure and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

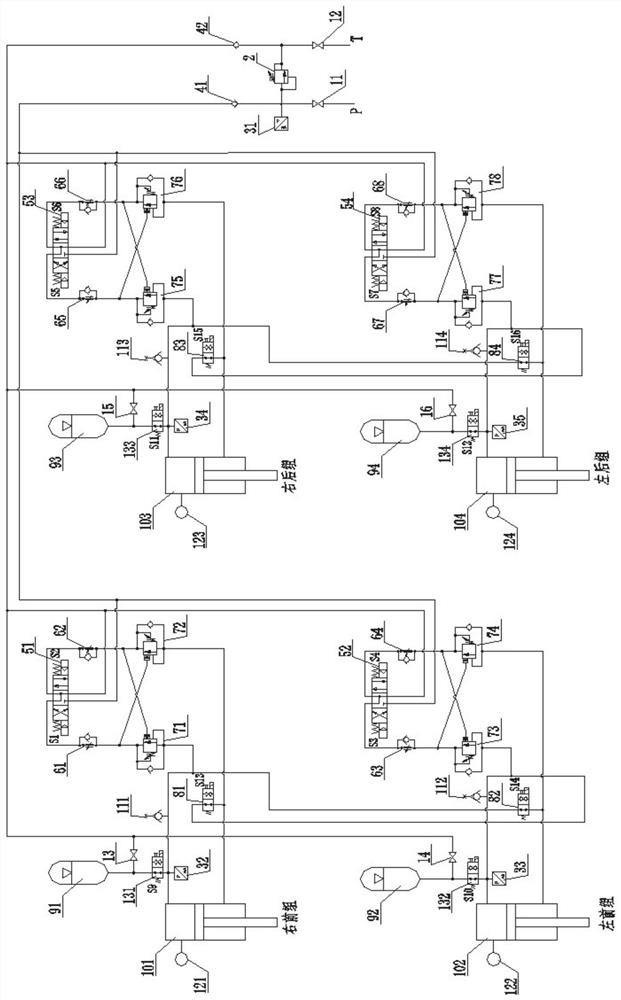

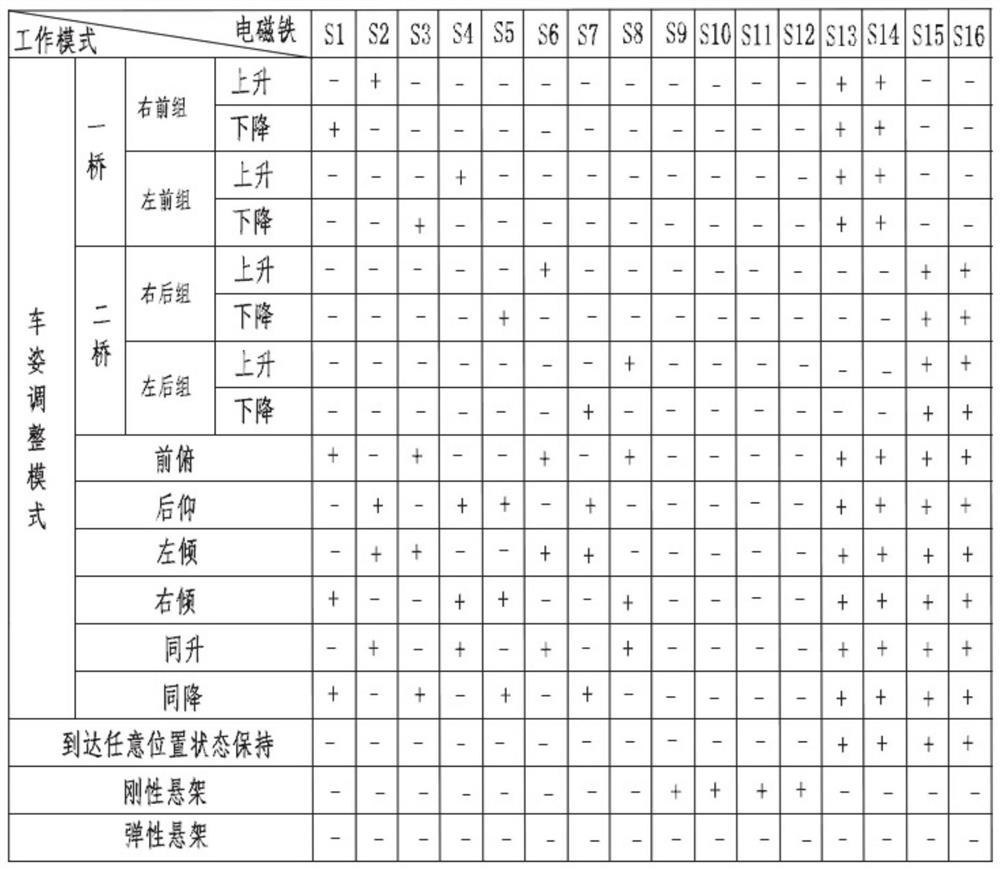

[0032] Example 1: Anti-rolling adjustable oil-pneumatic suspension hydraulic system for a two-axle vehicle

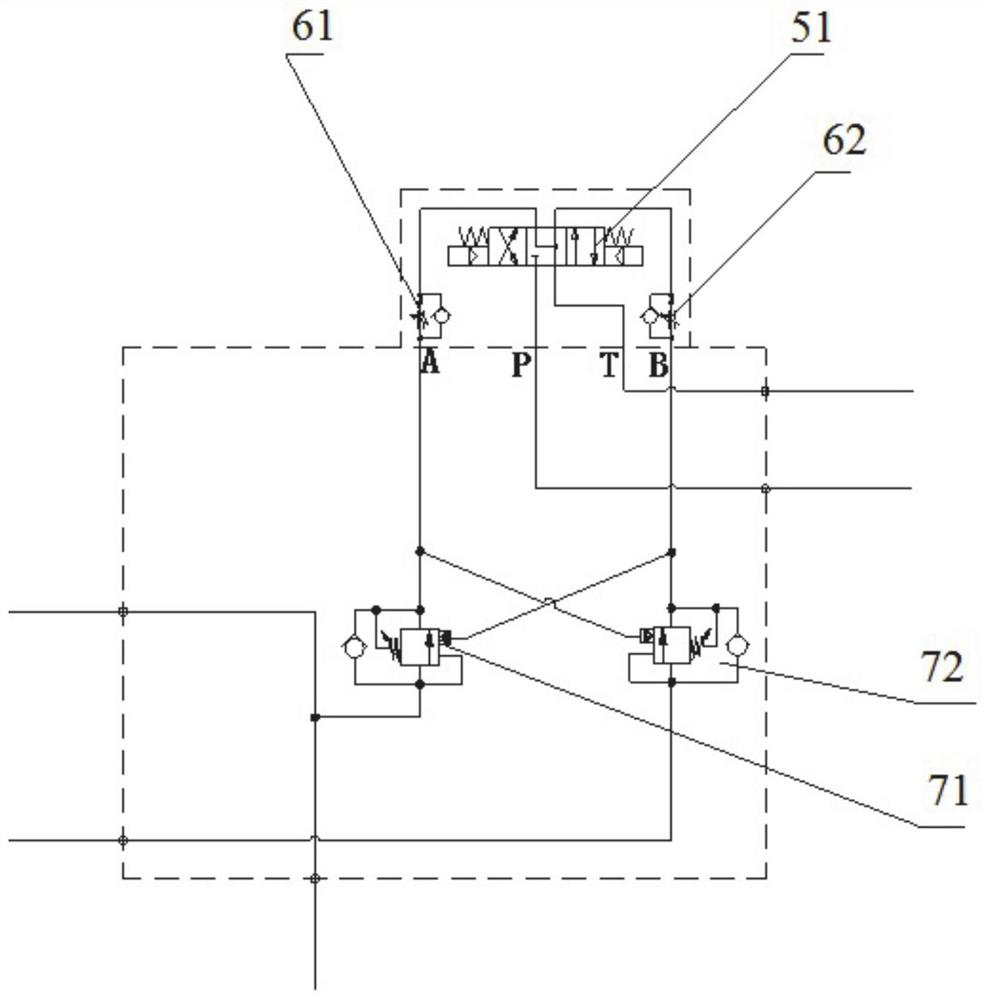

[0033] An anti-rolling adjustable oil-pneumatic suspension hydraulic system, including a front suspension hydraulic control unit, a rear suspension hydraulic control unit and an oil pipeline, and the front suspension hydraulic control unit includes a right front group suspension control mechanism and a left front group suspension The control mechanism, the rear suspension hydraulic control unit includes the right rear group suspension control mechanism and the left rear group suspension control mechanism, the front suspension hydraulic control unit and the rear suspension hydraulic control unit respectively correspond to one axle on the vehicle, through The oil pipeline includes the main oil inlet pipe, the main oil return pipe, and the pipes connecting the inside and between the front suspension hydraulic control unit and the rear suspension hydraulic control unit; a cu...

Embodiment 2

[0065] Example 2: Multi-axle vehicle roll adjustable oil-pneumatic suspension hydraulic system

[0066] The principle described in Embodiment 1 is also applicable to multi-axle vehicles, such as Figure 4 In the oil-pneumatic suspension hydraulic system of the three-axle vehicle, the right front oil cylinder 101 represents the right suspension oil cylinder of the first axle, the left front oil cylinder 102 represents the left suspension oil cylinder of the first axle, and the right rear oil cylinder 105 represents the right suspension oil cylinder of the second axle. The right rear oil cylinder 103 represents the right side suspension oil cylinder of the third axle, the left front oil cylinder 106 represents the left side suspension oil cylinder of the second axle, and the left front oil cylinder 104 represents the left side suspension oil cylinder of the third axle.

[0067] The rod cavity and the rodless chamber of the right rear oil cylinder 105,103 of the second axle right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com