A hydraulic interconnected isd suspension

An interconnection and suspension technology, which is applied in the suspension, interconnection system, transportation and packaging, etc., can solve the problems of complex structure of oil and gas springs, easy and slow leakage of gas, and troublesome maintenance, so as to improve anti-rolling performance, Good car passability and good anti-roll effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the patent of the present invention is described further.

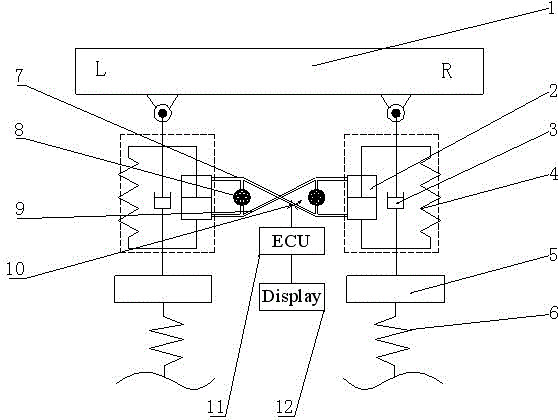

[0015] The patented rear suspension of the present invention includes a double-acting hydraulic cylinder 2 , a shock absorber 3 , a spring 4 , a connecting pipeline 7 , a hydraulic motor 8 , an interconnecting pipeline 9 , a throttle valve 10 , an electronic control unit 11 and a display screen 12 .

[0016] The double-acting hydraulic cylinder 2, the shock absorber 3, and the spring 4 are connected in parallel, the upper end is hinged to the sprung mass 1, and the lower end is hinged to the unsprung mass 5, and the upper and lower chambers of the left and right double-acting hydraulic cylinders 2 pass through two interconnected pipelines 9 Corresponding to the reverse interconnection, at the same time, the upper and lower chambers of the double-acting hydraulic cylinder 2 are connected to the hydraulic motor 8 through the connecting pipeline 7, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com