Independent suspension system and crane with the independent suspension system

A technology of independent suspension and frame, which is used in construction cranes, suspensions, elastic suspensions, etc., can solve the problems of poor force characteristics, poor trafficability, and impact on service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

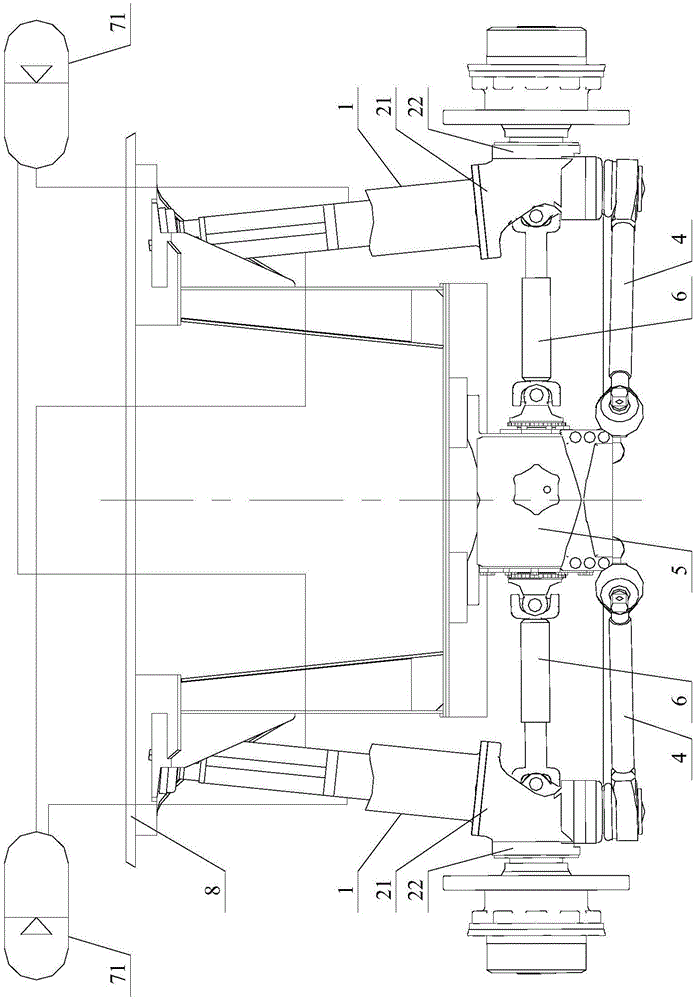

[0039] The core of the present invention is to provide an independent suspension system, which reduces the radial load on the suspension oil cylinder, provides a reliable guarantee for the independent movement of the left and right wheels, improves the control stability of the whole machine, and reduces maintenance costs. The present embodiment will be described in detail below in conjunction with the accompanying drawings.

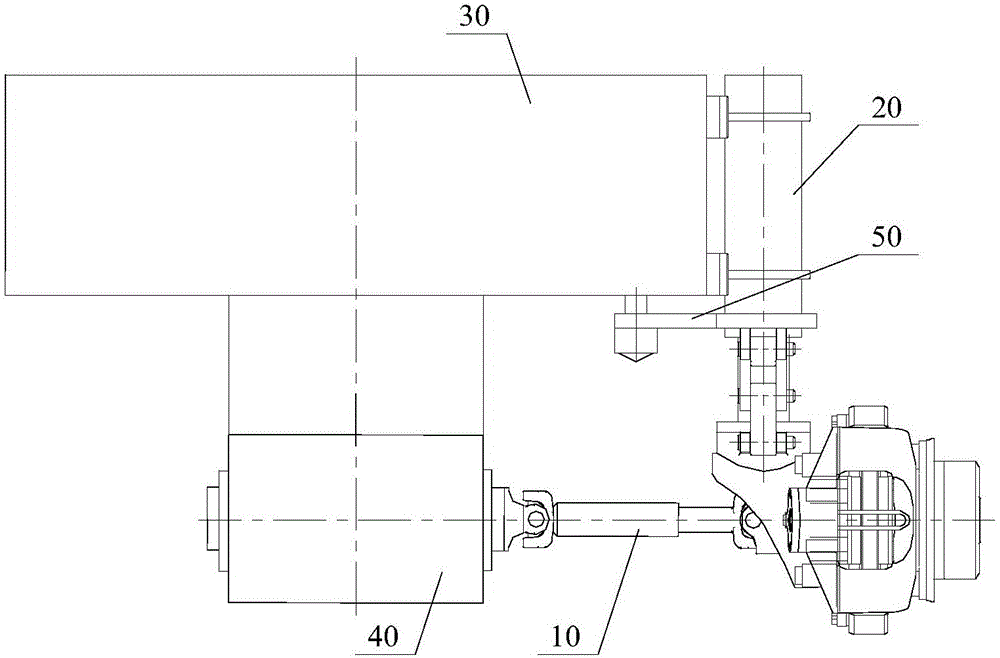

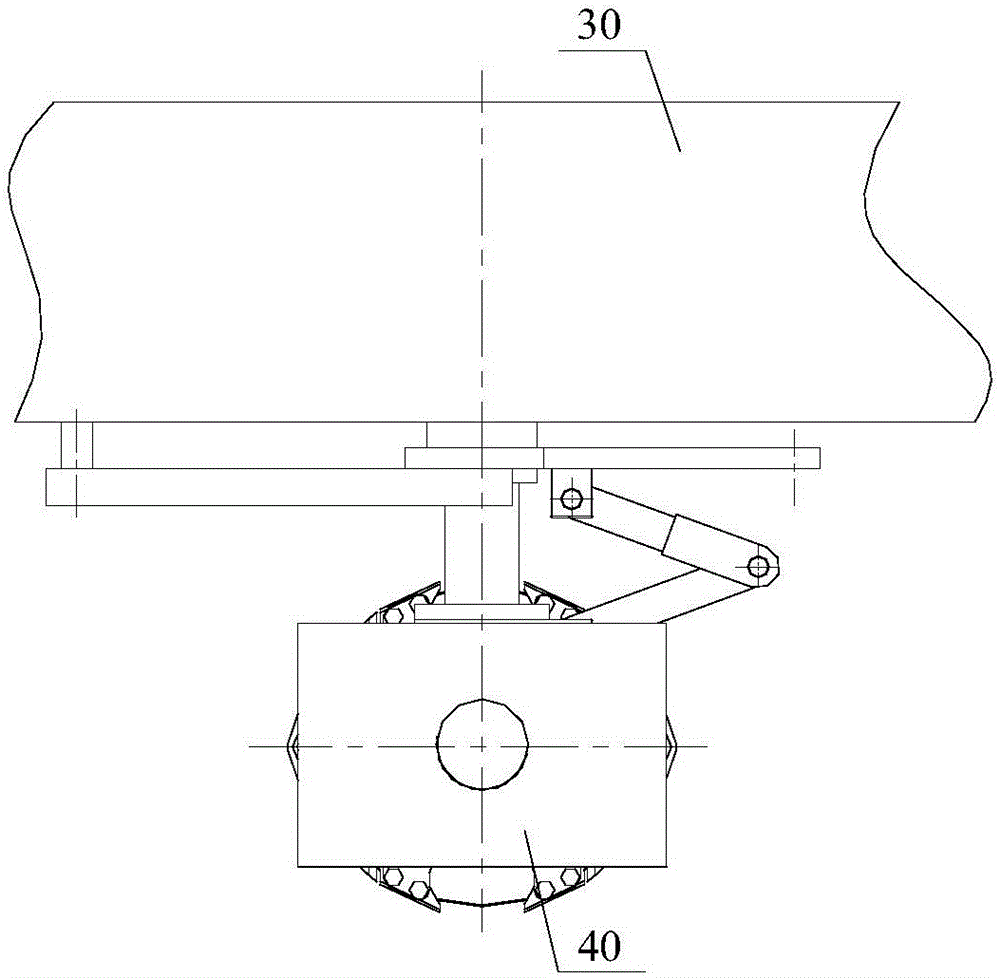

[0040] See image 3 and Figure 4 ,in, image 3 It is a front view of the independent suspension system described in this embodiment, which is a view formed from the front and rear directions, Figure 4 It is a top view of the independent suspension system in this embodiment.

[0041] Without loss of generality, this proposal takes the steering drive shaft as the main body for detailed description. It should be understood that the steering drive function does not constitute a limitation on the independent suspension system.

[0042] The two suspension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com