Power distribution method and device for four-wheel drive electric vehicle

A power distribution and electric vehicle technology, applied in the field of vehicles, can solve the problems of low efficiency of the motor system of four-wheel drive electric vehicles, and achieve the effect of improving the efficiency of the motor system, rational distribution, reducing energy consumption and adverse effects of battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

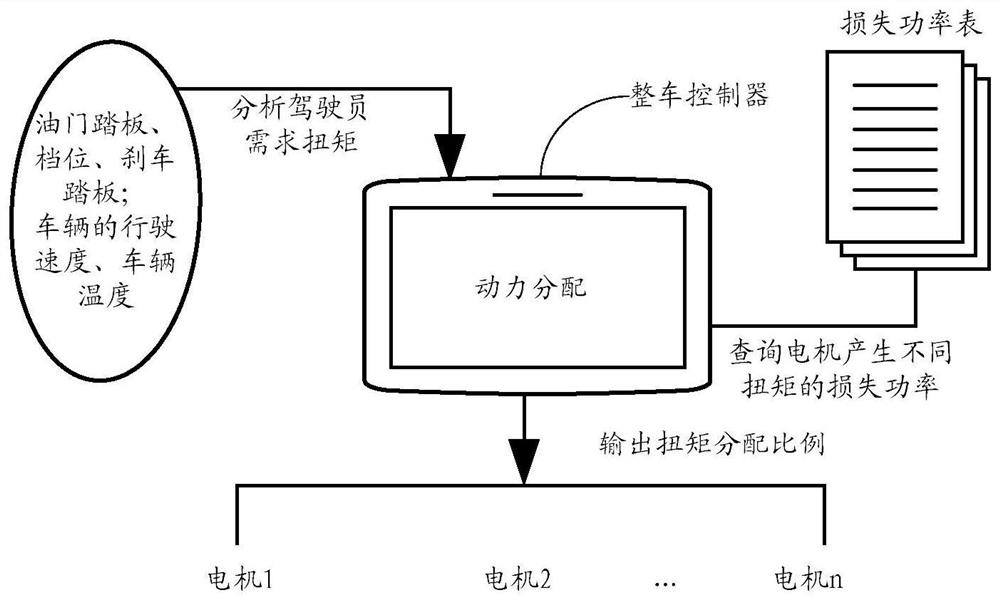

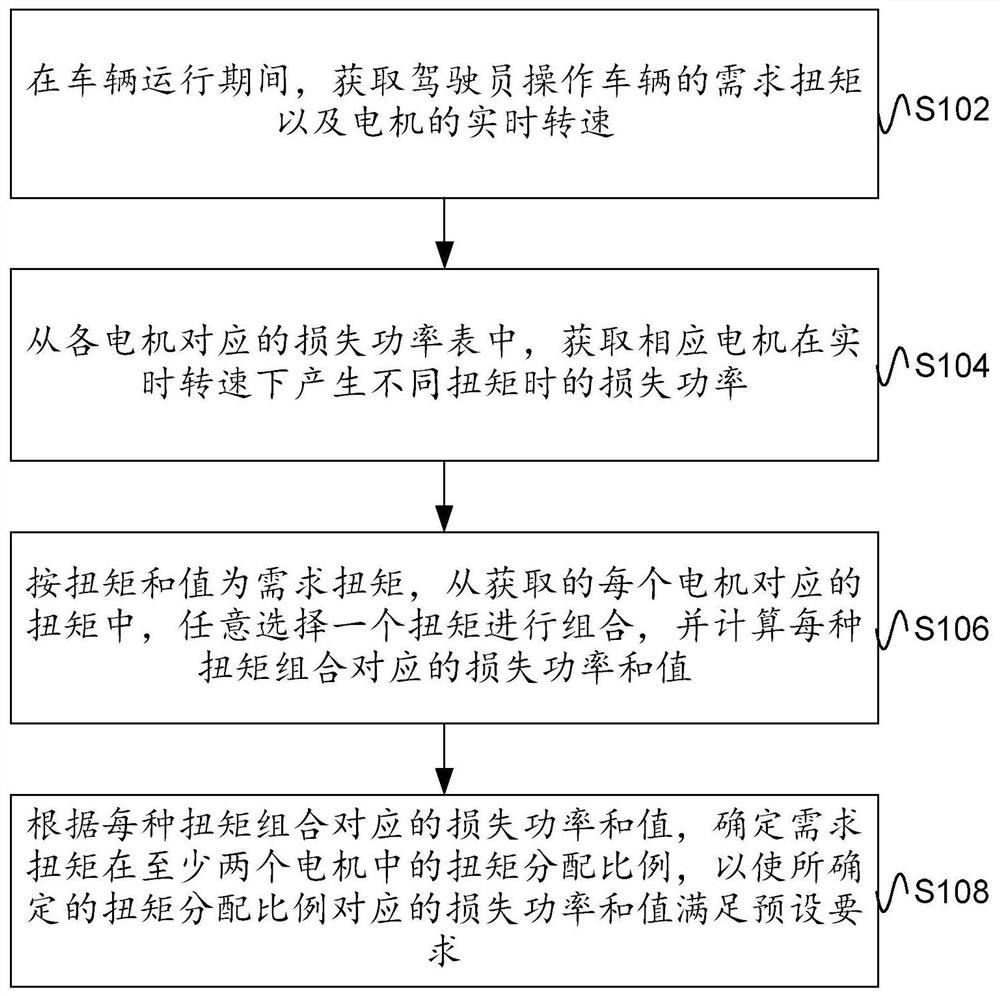

[0037] Based on the above application scenario architecture, figure 2 Schematic flow chart of the power distribution method for four-wheel drive electric vehicles provided in the embodiment of this specification Figure 1 , figure 2 methods in figure 1The vehicle controller in the vehicle is executed, and at least two motors are installed on the four-wheel drive electric vehicle, such as figure 2 As shown, the method includes the following steps:

[0038] S102, during the running of the vehicle, acquire the torque required by the driver to operate the vehicle and the real-time rotational speed of the motor.

[0039] Among them, the demanded torque of the driver to operate the vehicle reflects the driver's driving intention to the vehicle, which can be obtained by analyzing the driver's operation behavior on the vehicle and the running state of the vehicle itself.

[0040] For example, during the operation of the vehicle, the operation signal of the driver's operation of...

Embodiment 2

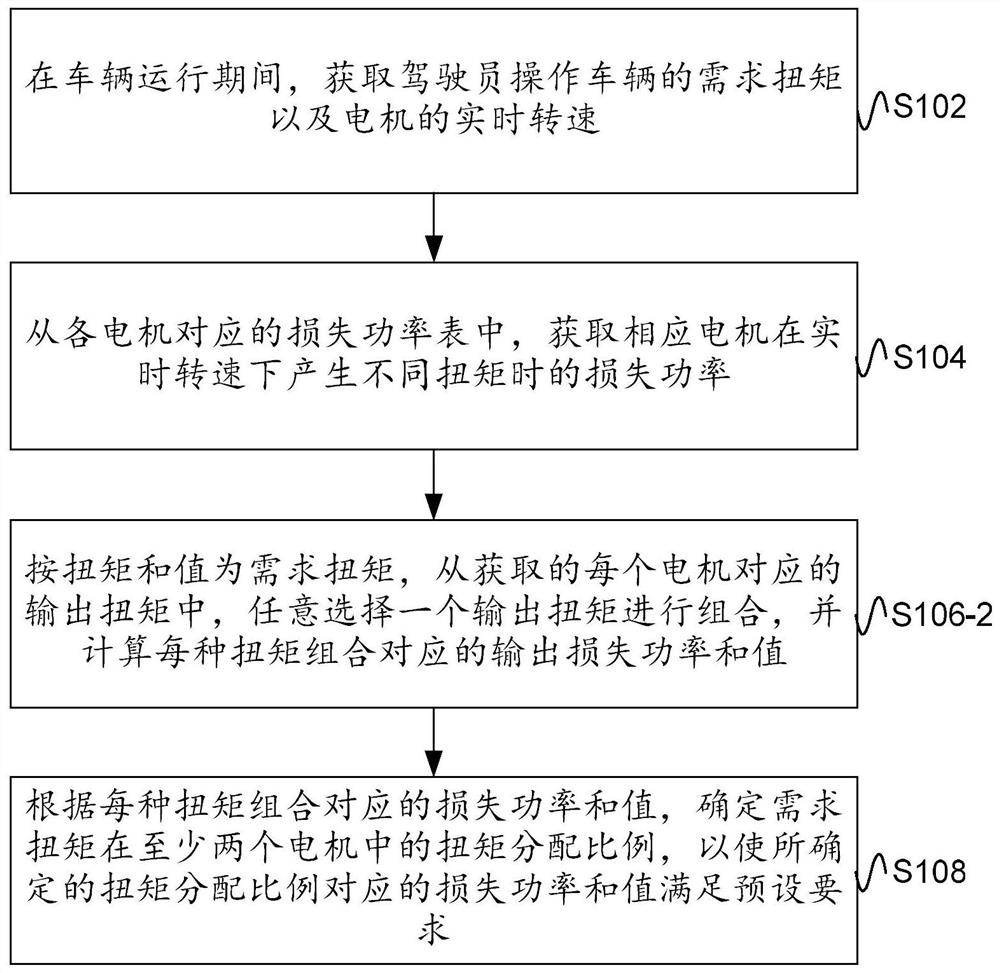

[0056] This embodiment is on the basis of embodiment one, to figure 2 The power distribution method of the four-wheel drive electric vehicle shown is expanded and supplemented.

[0057] In a specific embodiment, the loss power when the above-mentioned motor generates torque may include: the output power loss when the motor is in a working state and generates output torque; correspondingly, as image 3 As shown, step S106 may include:

[0058] S106-2, according to the torque and the value of the demand torque, from the obtained output torque corresponding to each motor, arbitrarily select an output torque for combination, and calculate the output loss power and value corresponding to each torque combination.

[0059] Among them, the output torque is defined as the torque actively output by the motor in the working state. According to the direction of the motor output torque, the output torque can be divided into positive and negative output torques; the process of the motor o...

example 1

[0089] Example 1: T d = 200, when n = 200, the power loss of the front and rear motors under different torque distribution methods is calculated by linear interpolation, and the total power loss table is obtained by summing as follows:

[0090] Table 4 Total Power Loss Table

[0091] T d

[0092] It can be seen from the table that under this working condition, when the rear motor does not work (that is, enters the dragging working condition), the total power loss is the smallest when the front motor outputs 206Nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com