Automatic sealing device for shiitake mushroom sticks

A technology for automatic sealing and shiitake mushroom sticks, applied in packaging, transportation packaging, mushroom cultivation and other directions, can solve problems such as affecting processing efficiency, breakage, air leakage, etc., and achieve the effect of ensuring the quality of sealing processing and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

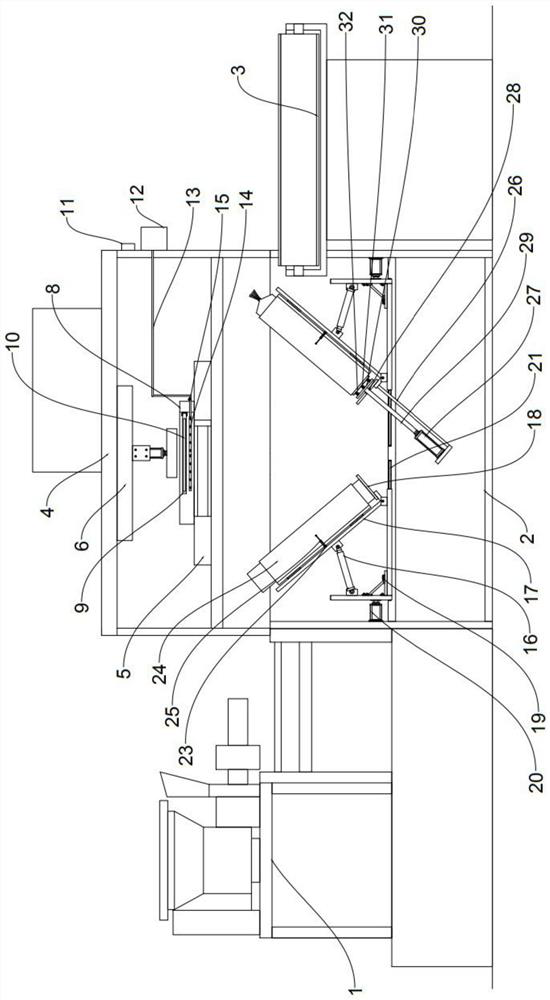

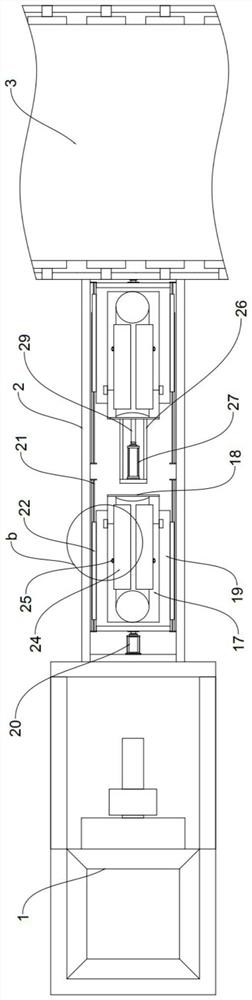

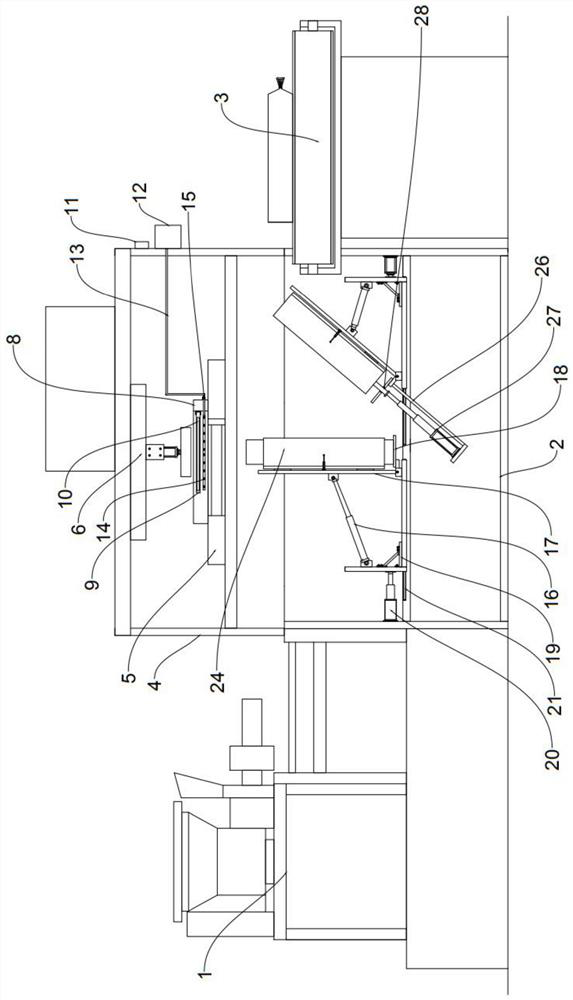

[0031] Embodiment: attached by specification Figure 1-10 It can be seen that this scheme includes a filler machine 1, a fixed frame 2, a conveyor 3 and a bacteria bag sealing machine 4, and its positional relationship and connection relationship are as follows, the fixed frame 2 is arranged on the discharge end of the filler machine 1, and the conveyor 3 is installed On one side of the fixed frame 2, the bacterial bag sealing machine 4 is installed on the fixed frame 2. The bacterial bag sealing machine 4 is composed of an aluminum buckle sealing mechanism 5, a hot-melt sealing mechanism and a positioning grabbing mechanism 6. The hot-melt sealing mechanism is installed On the top of the aluminum buckle sealing mechanism 5, the positioning grabbing mechanism 6 is installed above the hot-melt sealing mechanism, and the grabbing end of the positioning grabbing mechanism 6 can sequentially penetrate the hot-melt sealing mechanism and the aluminum buckle sealing mechanism 5 and ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com