Microbial fermentation device for wastewater treatment

A technology for microbial fermentation and wastewater treatment, applied in biological treatment devices, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of large footprint and difficulty in separating wastewater and sludge, and reduce the The effect of occupying an area, improving efficiency and length, and reducing difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

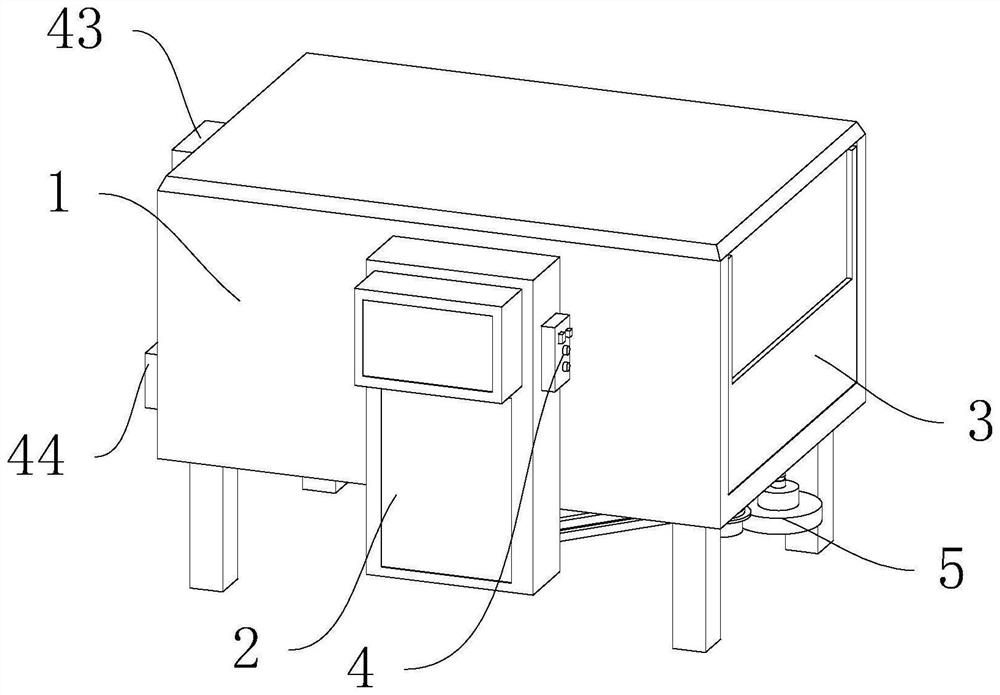

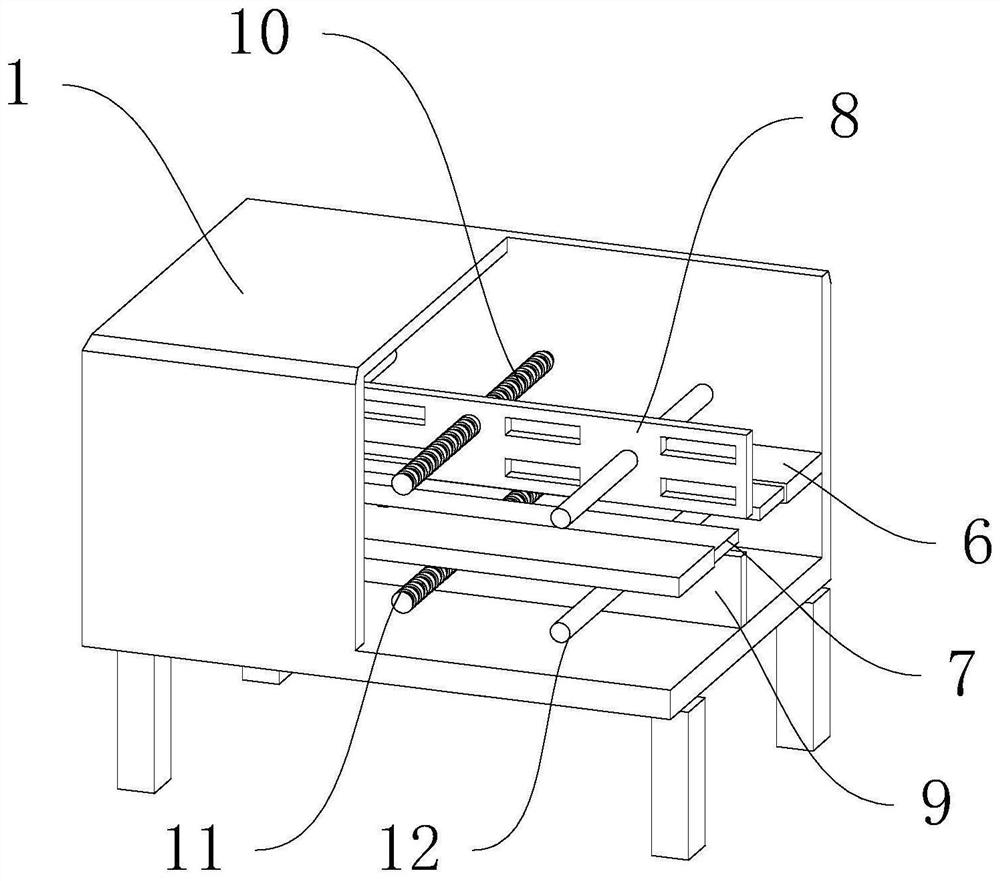

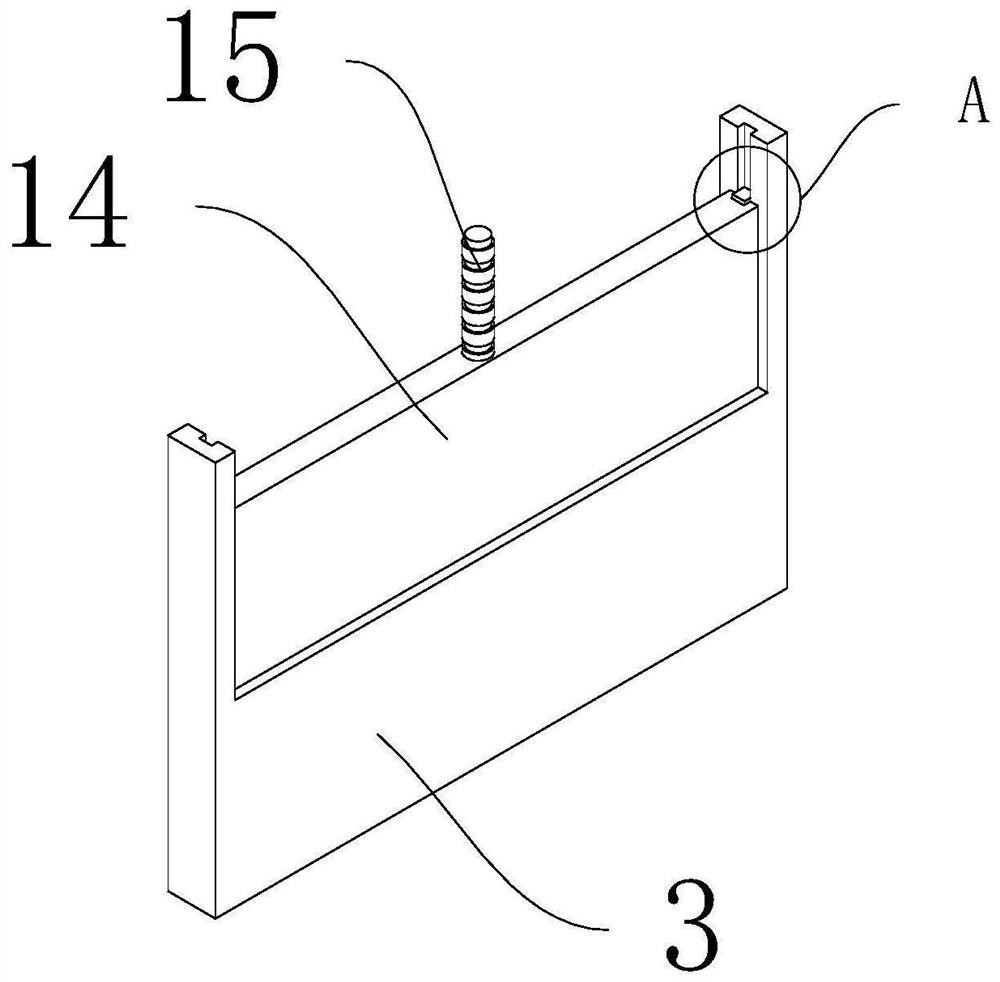

[0033] refer to Figure 1-11 , a microbial fermentation device for waste water treatment, comprising a box body 1, a feed inlet 43 and a discharge port 44 are respectively installed at the upper and lower ends of one side of the box body 1, and a first substrate 3 is installed at the bottom of one side of the box body 1, The top of the first base plate 3 is sleeved with a first telescopic plate 14, and the middle part of the first telescopic plate 14 is installed with an adjusting screw 15. One end of the adjusting screw 15 protrudes from the bottom of the first base plate 3 and a second friction wheel 5 is installed. A mounting base 13 is fixed at the joint between the top of the wheel 5 and the adjusting screw 15, and a second base plate 6 is installed between both sides of the inside of the box body 1, and the top of the second base plate 6 is clamped with a second telescopic plate 7, and the second base plate 6. A first reciprocating screw 10 and a second reciprocating scr...

Embodiment 2

[0039] refer to Figure 3-4 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that both sides of the first telescopic plate 14 are connected to the box body 1 with limiting plates 16, and both sides of the limiting plate 16 are connected to the first telescopic plate. Limiting slots 18 are opened at the joints of the plates 14, and limiting strips 17 are installed at the joints of the first expansion plate 14 both sides with the limiting plate 16, and the limiting strips 17 correspond to the positions of the limiting grooves 18, and the limiting The cross-sectional size of the position bar 17 matches the limit groove 18 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap