Heat dissipation and heat absorption synchronous cross type heat exchanger

A heat exchanger, heat dissipation and heat absorption technology, used in heat exchange equipment, heat exchanger shells, indirect heat exchangers, etc., can solve the problem of uneven temperature of phase change energy storage materials, heat dissipation and heat absorption of phase change energy storage materials Can not be synchronized and other problems, to achieve the effect of low heat damage, high thermal efficiency and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

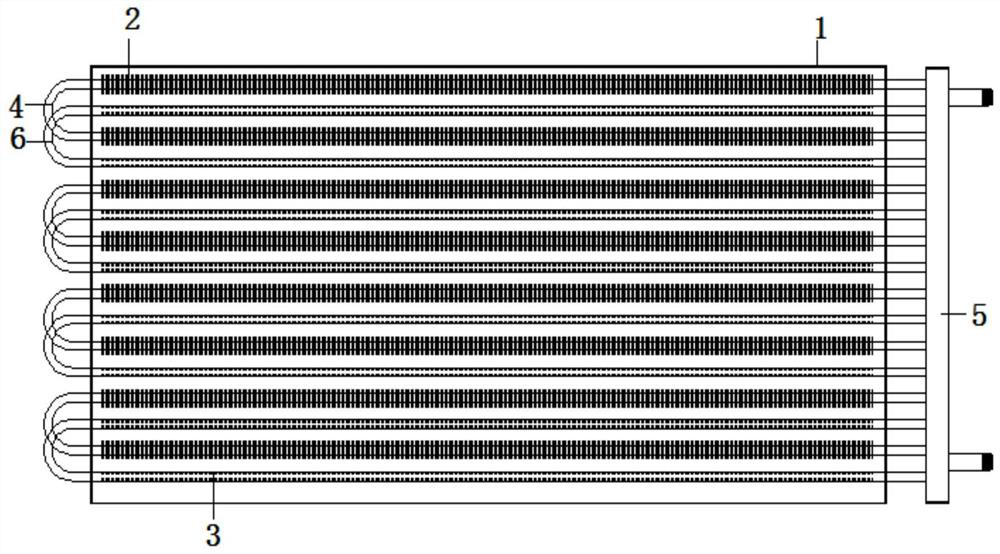

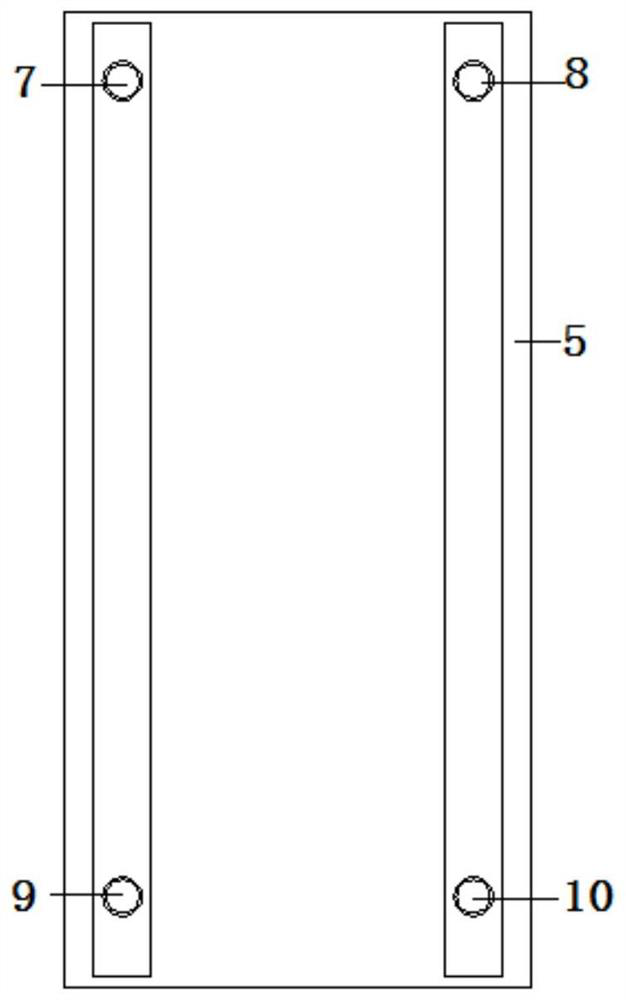

[0015] Such as figure 1 and figure 2 The shown heat dissipation and heat absorption synchronous cross-type heat exchanger includes a shell 1, the shell 1 is a stainless steel shell, and the inside of the shell 1 is fixed with a plurality of radiating tubes 2 and heat absorbing tubes 3, and the radiating tubes 2. One end is connected to the elbow 4 through the heat dissipation pipe, and the other end is connected to the concentration pipe 5. One end of the heat absorption pipe 3 is connected to the elbow 6 through the heat absorption pipe, and the other end is connected to the concentration pipe 5. The upper end of the concentration pipe 5 has a The heat transfer oil inlet 7 and the cold water inlet 8 have a hot water outlet 9 and a heat transfer oil outlet 10 at the lower end. The heat transfer oil inlet 7 and the heat transfer oil outlet 10 communicate with the heat dissipation pipe 2. The heat-absorbing pipe 3 communicates.

Embodiment 2

[0017] Such as figure 1 and figure 2 The shown heat dissipation and heat absorption synchronous cross-type heat exchanger includes a shell 1, and the inside of the shell 1 is fixed with a plurality of heat dissipation pipes 2 and heat absorption pipes 3, and the number of the heat dissipation pipes 2 and heat absorption pipes 3 is They are all even numbers, installed horizontally inside the housing 1 from top to bottom, and the adjacent two of the heat dissipation pipes 2 from top to bottom are set as a group, and one end of each group of heat dissipation pipes 2 is connected through the heat dissipation pipe connecting elbow 4, The other end is connected to the concentrating pipe 5, and the inside of the concentrating pipe 5 is provided with a heat dissipation pipe passage, and the heat dissipation pipe passage is connected to two sets of heat dissipation pipes 2 up and down, and two adjacent heat-absorbing pipes 3 from top to bottom are set as one One end of each group of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com