Three-dimensional laser radar positioning and navigation method for intelligent inspection and inspection robot

A three-dimensional laser and radar positioning technology, applied in the field of inspection robots, can solve the problems of affecting the positioning accuracy, positioning loss, and inability to effectively describe the three-dimensional environmental space, and achieve the effect of strong anti-electromagnetic interference and improved inspection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

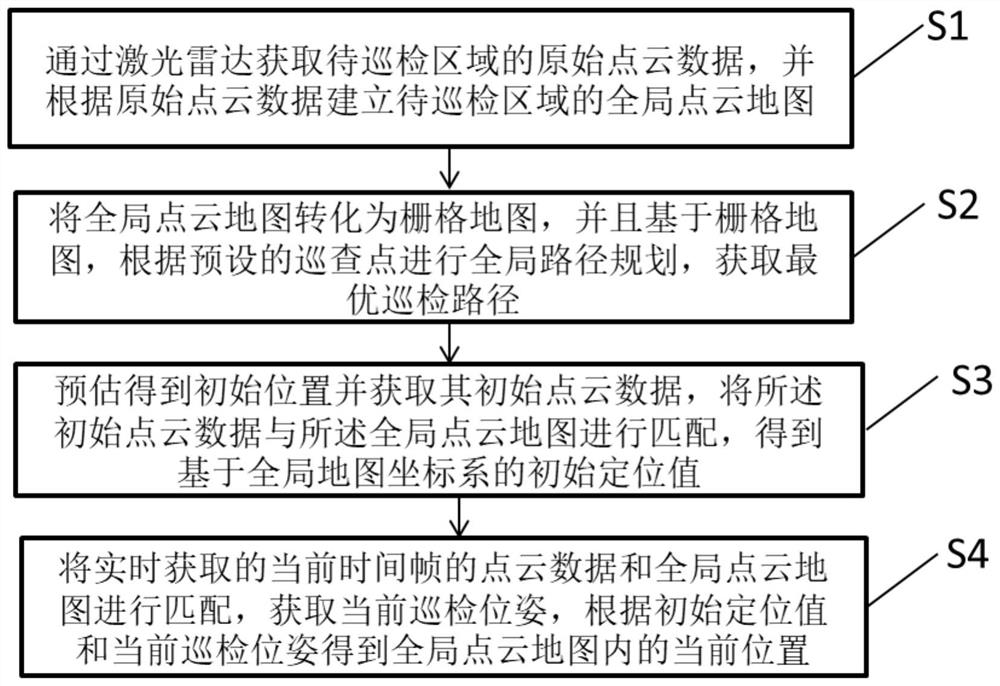

[0063] See figure 1 , The present embodiment provides a three-dimensional laser radar navigation method for intelligent data logging comprises the steps of:

[0064] S1: obtaining raw point cloud data to be inspection area by a laser radar, and the inspection zone to be build the global map based on the original point cloud point cloud data;

[0065] S2: the global point cloud map into a grid map and grid-based map, global path planning conducted according to a preset inspection points, inspection obtain optimal path;

[0066] S3: obtain an initial position estimate and acquires its initial point cloud data, the global data and the initial point cloud point cloud map matching to obtain an initial target value based on the global map coordinate system;

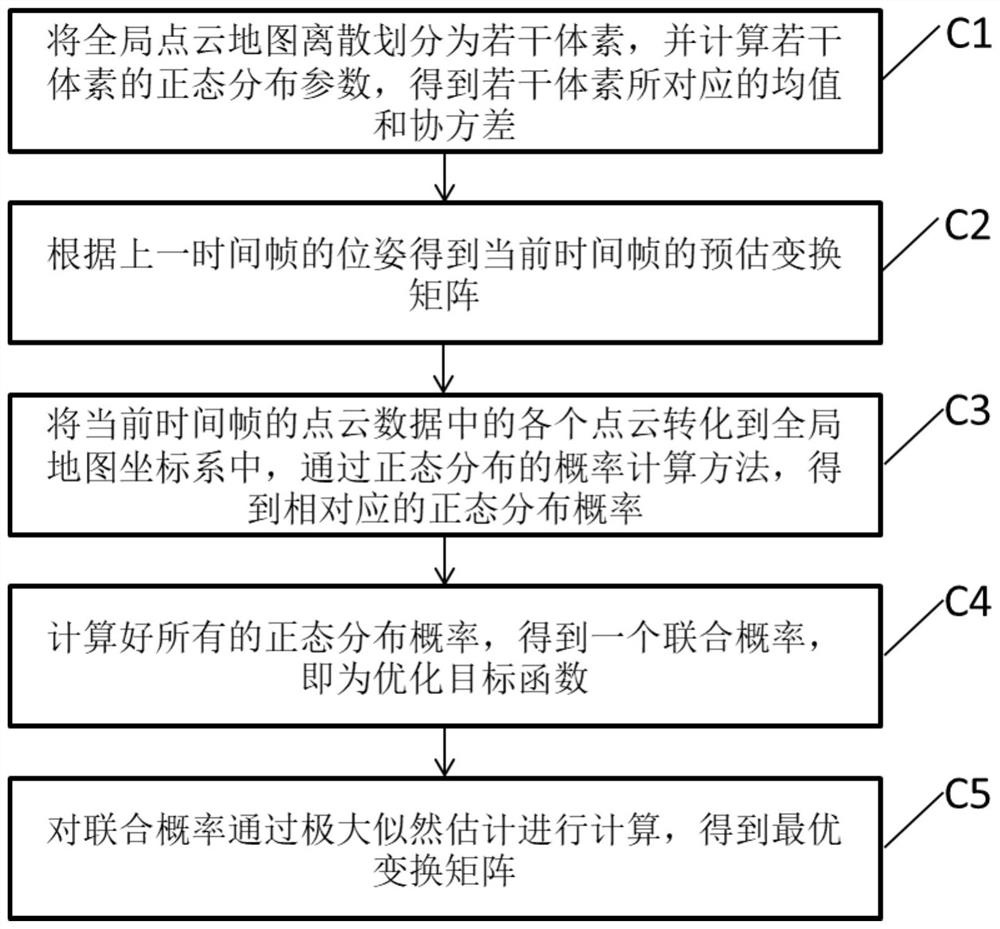

[0067] S4: point cloud point cloud data and a global map of the current time acquired in real time to match the frame, acquires the current pose inspection, to give the current position within the global map based on the point clou...

Embodiment 2

[0091] See Figure 5 An inspection robot includes:

[0092] The scanning device 1: inspection for scanning the area to be different, the raw point cloud data obtained in different regions of the inspection to be real-time data point and the current position of the millimeter-wave cloud radar data. In particular, the scanning laser radar apparatus 1 comprises a three-dimensional millimeter-wave radar 11 and 12; three-dimensional laser radar 11 for acquiring the raw point cloud data and the point cloud data in real time; three-dimensional laser radar millimeter-wave radar 12 for detecting the surrounding obstacle information, with 11 scans. Using a three-dimensional laser radar 11 to implement the present embodiment, it is possible to achieve a good three-dimensional perception of the environment, independent path planning and navigation functionality.

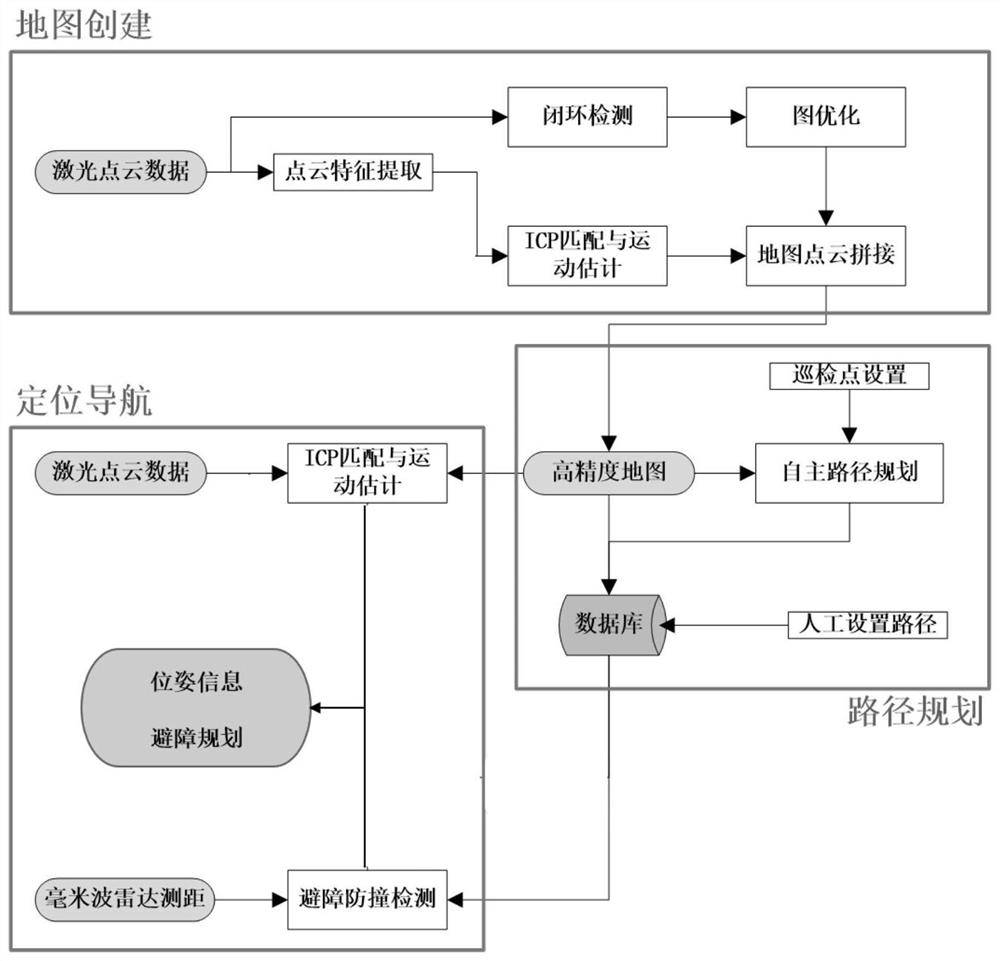

[0093] Map Building Blocks 2: raw point cloud data is used to extract features optimized to obtain point cloud data, the point clou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com