Test device and method for eliminating residual stress through pre-rotation of turbine blank disc

A technology of residual stress and test device, which is applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc. performance effect

Pending Publication Date: 2020-12-01

ZHEJIANG HIRO AVIATION TECH CO LTD +2

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The present invention aims at the problem that it is difficult to eliminate the residual stress of the existing aero-engine and gas turbine turbine blank disk, and provides a test device and method for pre-rotating the turbine blank disk to eliminate the residual stress. The present invention uses the pre-rotation method to achieve the purpose of eliminating the residual stress , first install the blank turbine disc

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Login to View More

Abstract

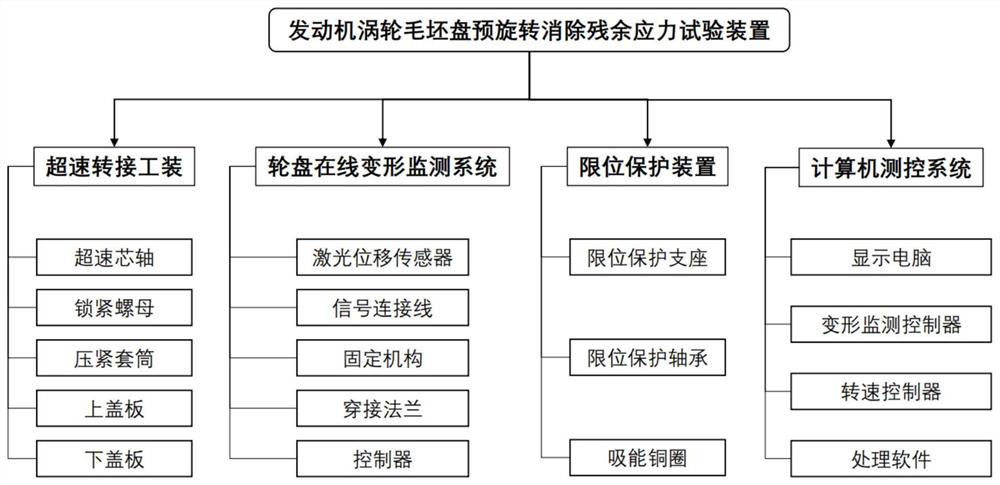

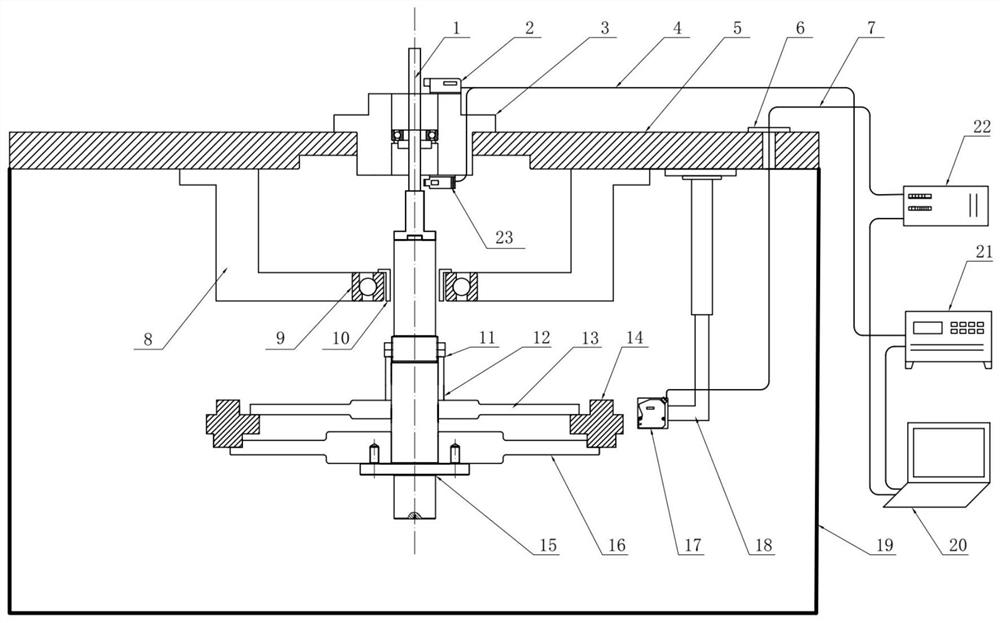

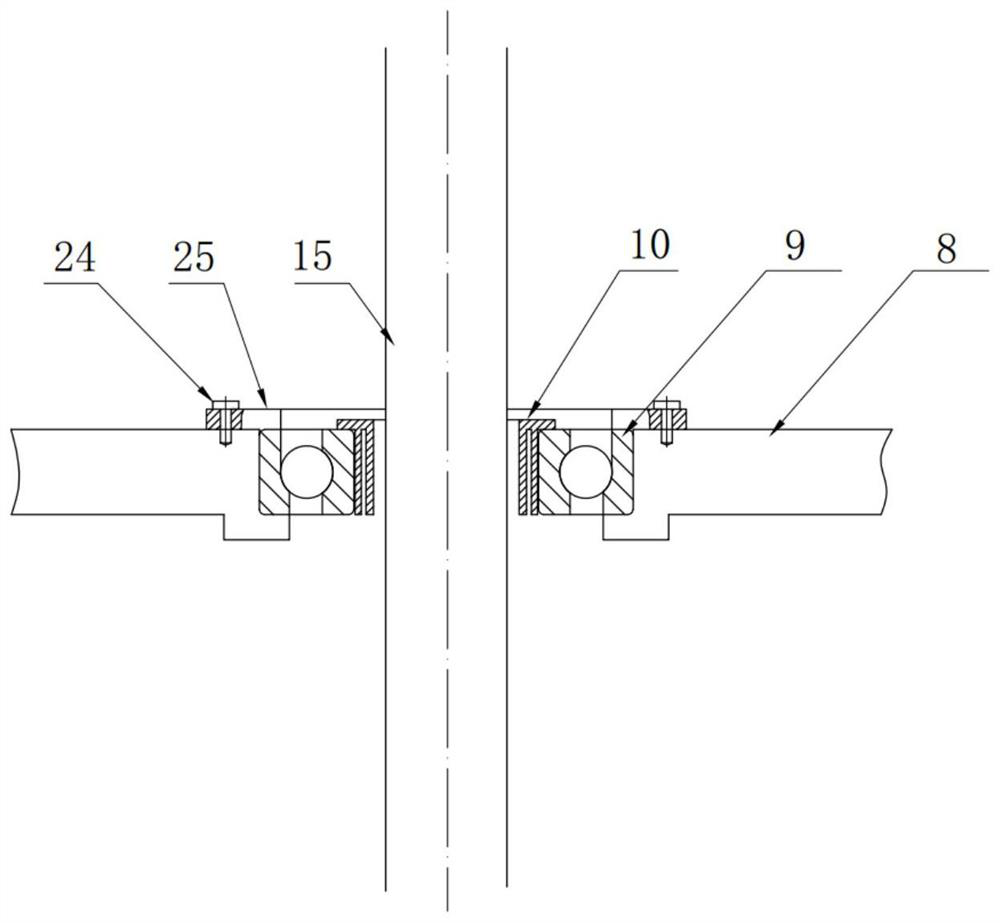

The invention discloses a test device and method for eliminating residual stress through pre-rotation of a turbine blank disc, and belongs to the technical field of aero-engines and gas turbines. A driving main shaft in the device drives a switching tool to rotate, the switching tool comprises a core shaft, a turbine blank disc and a pressing part, a limiting protection mechanism is arranged on the outer side of the core shaft, the top of the core shaft is connected with the driving main shaft, a flange base for installing the turbine blank disc is arranged at the bottom of the core shaft, andthe turbine blank disc is fixed through the pressing part. In the testing process, the rotating speed, vibration and deformation of the turbine blank disc are monitored and displayed in real time through the monitoring system, and the pre-selected rotating speed increasing and decreasing process is controlled by setting the target rotating speed, the target deformation amount and the vibration limiting value. The purpose of eliminating overspeed pre-rotation of the residual stress of the turbine blank disc of the aero-engine and the gas turbine is achieved, the residual stress in the turbineblank disc is greatly reduced, the mechanical performance of the turbine blank disc is improved, machining deformation is reduced, and the production period is shortened.

Description

technical field [0001] The invention relates to a test device and method for overspeed pre-rotation of blank disks to eliminate residual stress, which are used in the technical fields related to the production, processing and application of turbine disks of aeroengines and gas turbines. Background technique [0002] The turbine discs of aero-engines and gas turbines work in a high-temperature and high-stress environment for a long time, and have extremely high requirements on material performance. They need to have high temperature resistance and high strength characteristics at the same time. For this reason, special forging and heat treatment processes are required. In addition, the high energy conversion efficiency requirements of aero-engines make the turbine rotor structure must have extremely high dimensional accuracy and long-term dimensional stability. [0003] The complex forging and heat treatment process of the turbine disk material will generate extremely large r...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G06F30/23G01M13/00G01L5/00G06F119/14

CPCG06F30/23G01M13/00G01L5/0047G06F2119/14

Inventor 陈传勇宣海军张北江张文云瞿明敏黎晓宇张国栋黄爱华田成刚

Owner ZHEJIANG HIRO AVIATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com