Method and system for determining production progress and order inventory, and edge server

A production schedule and production line technology, applied in the field of the Internet of Things, can solve problems such as inaccuracy and untimely order inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] As mentioned above, for factories with floating factory working hours, it is usually manually set the end time of factory work manually, and after receiving the information of the end of factory working time, the order progress of each production link of the production line is manually counted. Then give feedback to the customer. On the one hand, this solution requires manual maintenance. On the other hand, due to the manual setting, there may be problems of advance, lag or forgetting. Therefore, it is impossible to accurately and timely judge the production progress, which in turn leads to the inability to timely and accurately check the order. It may even be delayed until the next day for production inventory, making it difficult to accurately and timely feedback the production progress to customers.

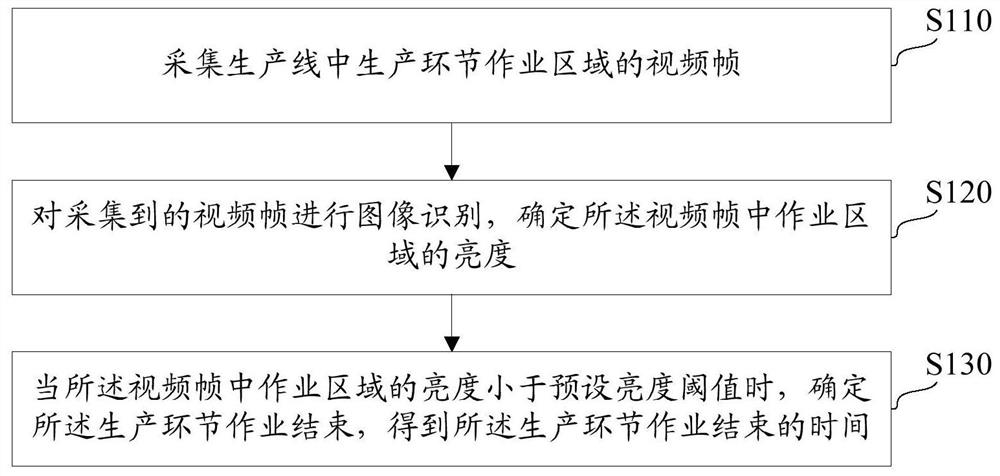

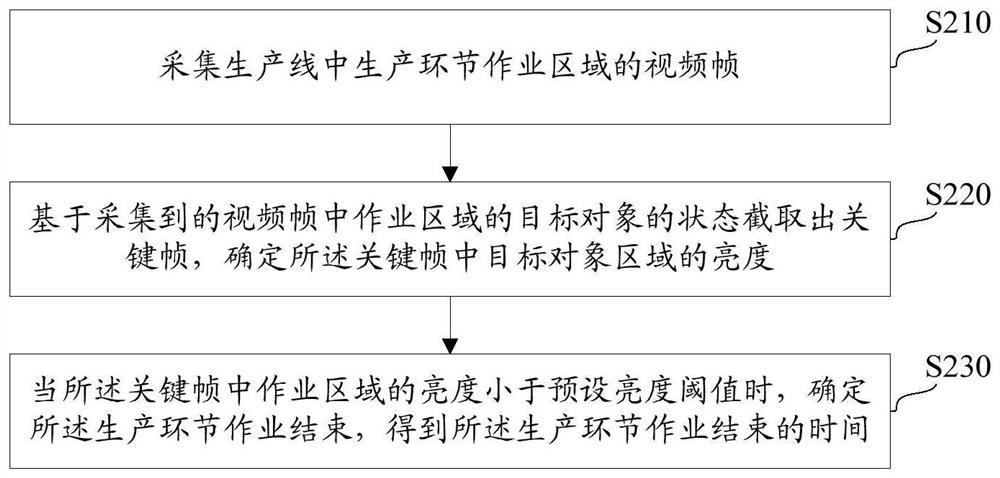

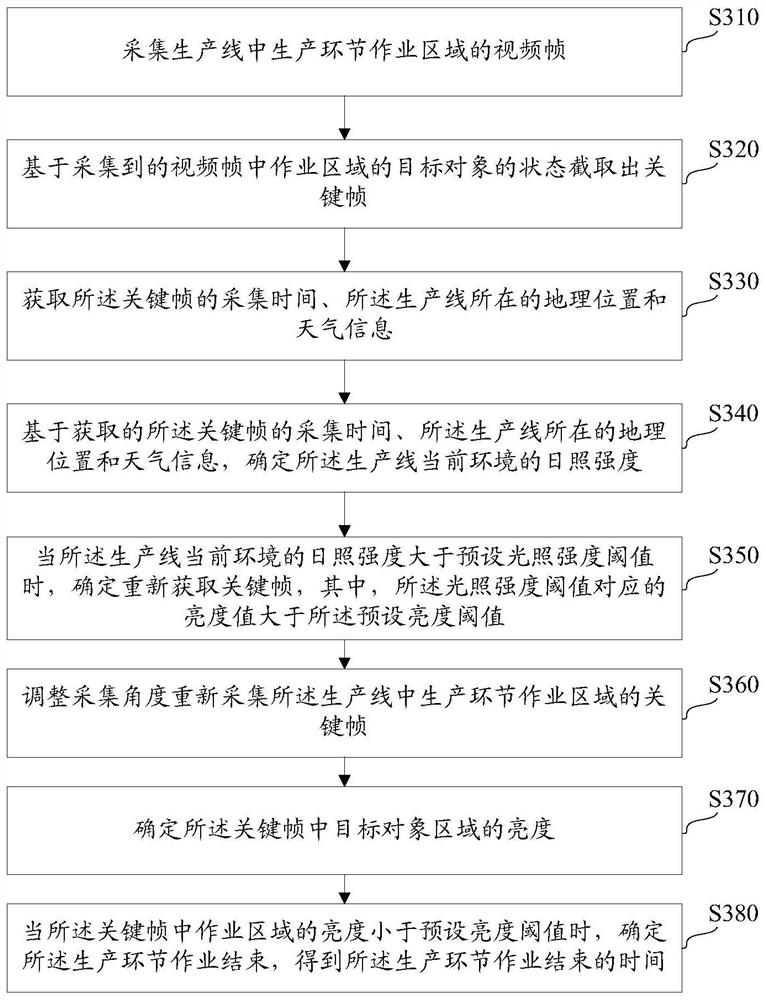

[0079] In view of the above problems, the embodiment of this specification determines the brightness of the working area in the video frame by performing image recognit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com