Carbon fiber composite plate layering defect air coupling Lamb wave ultrasonic detection method based on modal decomposition imaging algorithm

A composite material board, air coupling technology, applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, complex mathematical operations, processing response signals of detection, etc., can solve problems such as secondary pollution, prolong service life and avoid secondary pollution Effects of pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

[0061] An air-coupled Lamb wave ultrasonic detection method for delamination defects of carbon fiber composite material plates based on a modal decomposition imaging algorithm, the detection method comprises the following steps:

[0062] Step 1: Connect the device and debug;

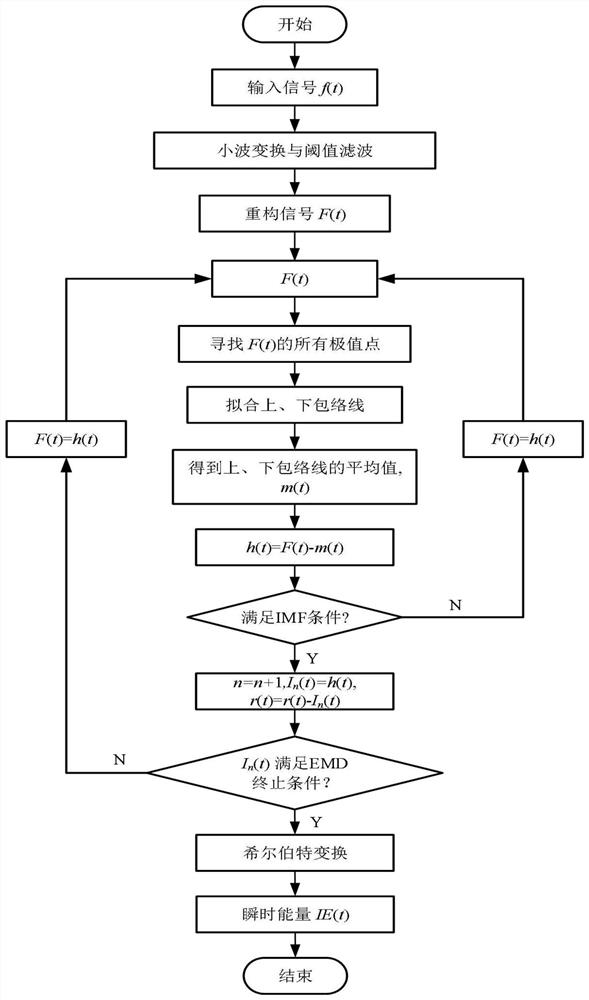

[0063] Step 2: Process the signal detected based on Step 1 through modal decomposition;

[0064] Step 3: Feature extraction and analysis are performed on the instantaneous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com