Automatic violin tuning device and operation method thereof

A driving device, automatic technology, applied in the direction of stringed instruments, instruments, musical instruments, etc., can solve the problems of wood wear, inability to tune, affect the value, etc., to achieve the effect of easy tuning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

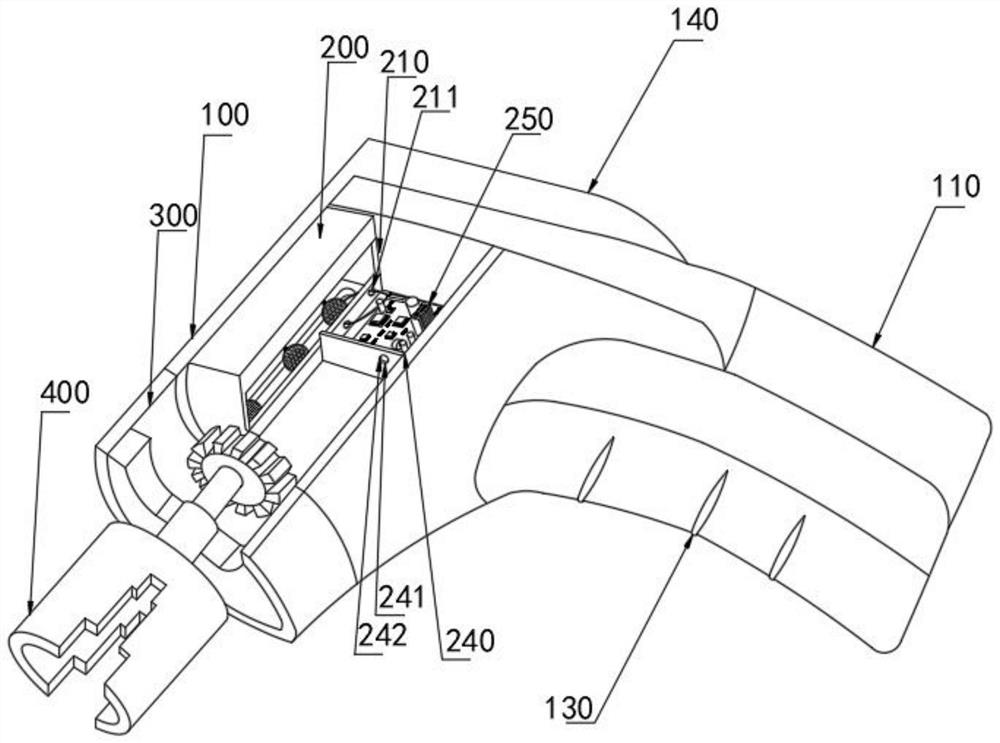

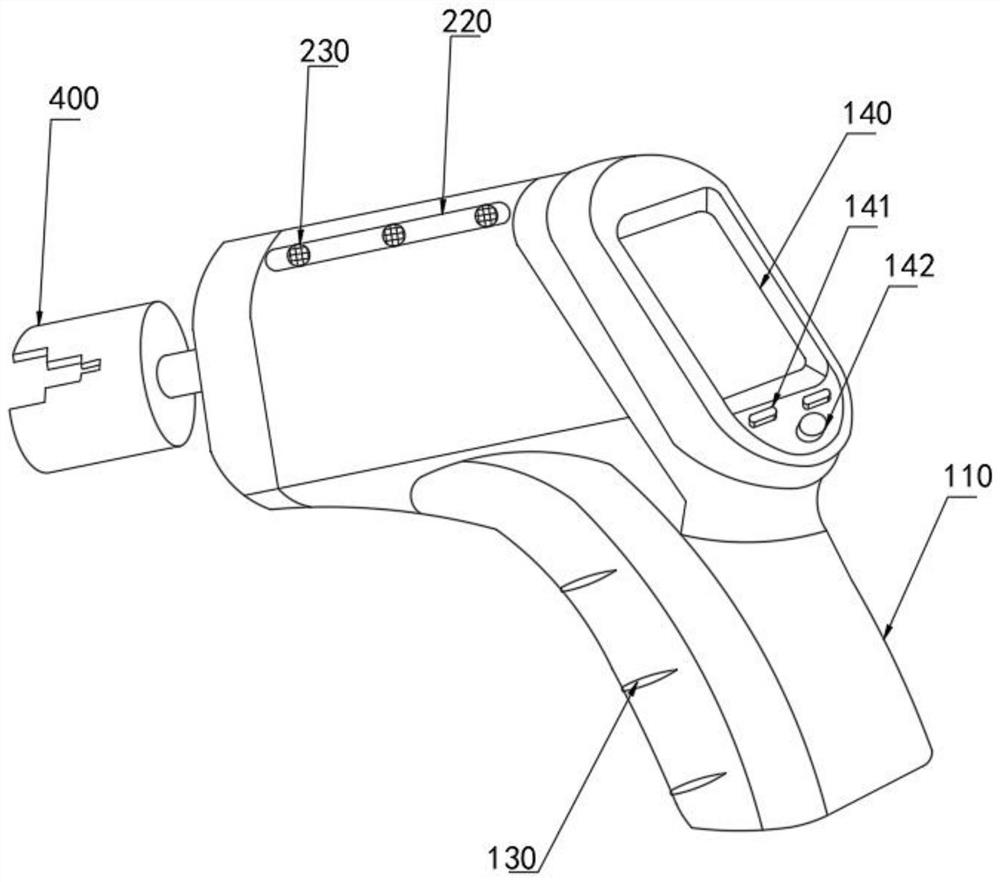

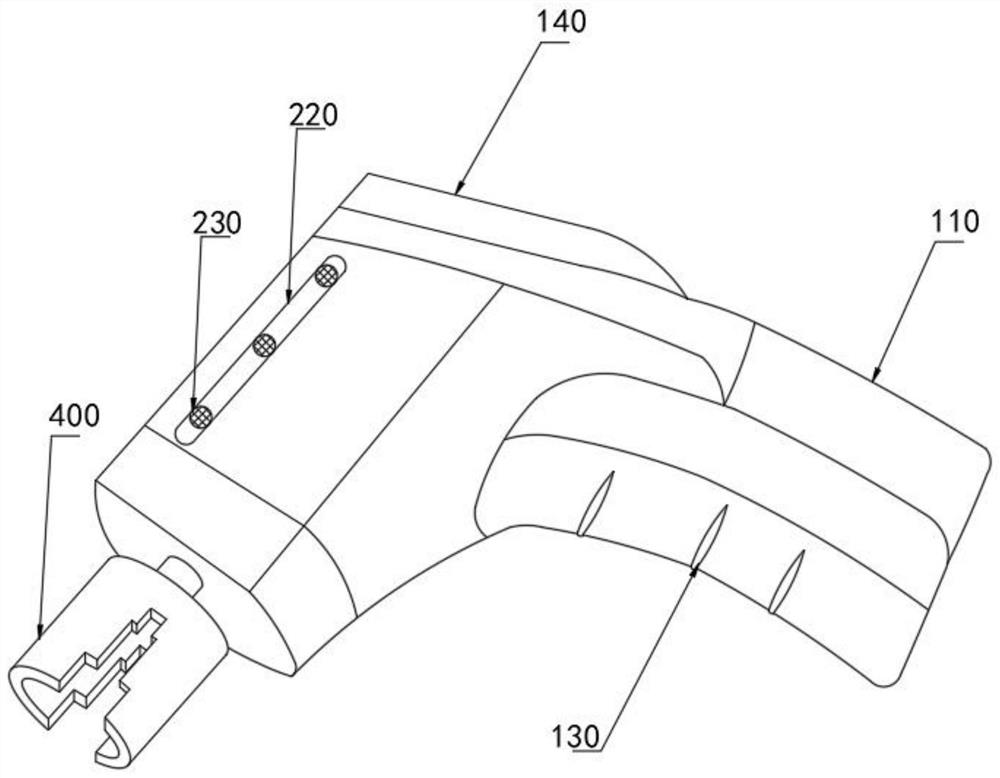

[0029] Embodiment 1, with reference to attached Figure 1-6 , a violin automatic tuning device and its operating method provided by the present invention, comprising a housing 100, a sound pickup device 200, a drive device 300 and a movable head 400, the two sides of the inner wall of the housing 100 are provided with a sound pickup device 200, so The sound pickup device 200 includes a limiting box 210, one side of the limiting box 210 is provided with a through hole 211, and one side of the limiting box 210 is provided with a mounting groove 220, and the mounting groove 220 is connected with the outer wall of the housing 100 , the inner wall of the installation groove 220 is fixedly equipped with a pickup board 230, the pickup board 230 is provided with three groups, the side of the limit box 210 is fixedly installed with a partition 240, and the bottom of the partition 240 is fixedly installed with a support plate 150, the inner wall of the partition 240 is fixedly equipped ...

Embodiment 2

[0038] A violin automatic tuning operation method, the operation steps are: plug the movable head-400 on the violin tuner, pluck the strings, or pull the strings, and the pickup board array module 180 transmits data to the pickup chip 250, the pick-up chip 250 converts the error value and controls the motor 310 to rotate, the motor 310 drives gear one to rotate at 320 degrees, gear one 320 drives gear two to rotate at 340 degrees, gear two 340 drives gear three to rotate at 350 degrees, gear three 350 drives gear four to rotate at 360 degrees, Gear 4 360 drives movable head 1 400 to rotate through gear shaft 2 370, and determines the rotation direction and speed of movable head 1 400 according to the larger value, so as to achieve the effect of automatic tuning.

Embodiment 3

[0040] Refer to the attached Figure 7 , a violin automatic tuning device and its operation method of this embodiment, also includes movable head two 410;

[0041] Further, the left side of the driving device 300 is movably connected with the movable head 2 410. Specifically, the movable head 2 410 is made of chrome-plated alloy steel with a large torque range. There is a fine-tuning tuner on the drawing board at the bottom of the violin. Smaller, the movable head 2 410 has a regulating effect on the fine-tuning device.

[0042] The specific implementation scenario is: when using the present invention, workers in the field need to replace the activity header 1 400 with the activity header 2 410 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com