Power cable wire drawing machine capable of uniformly drawing wires

A technology for power cables and wire drawing machines, which is used in cable/conductor manufacturing, circuits, electrical components, etc., and can solve problems such as water waste and different cable brittleness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

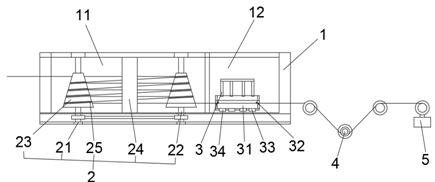

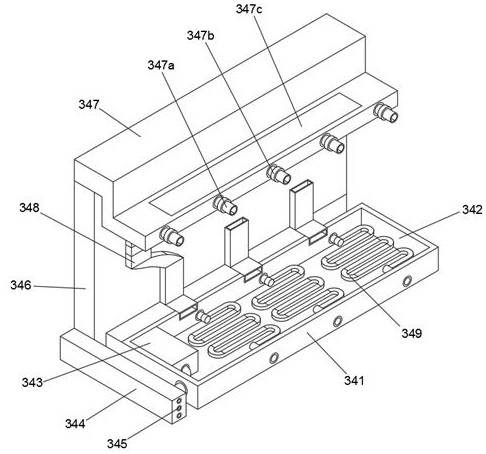

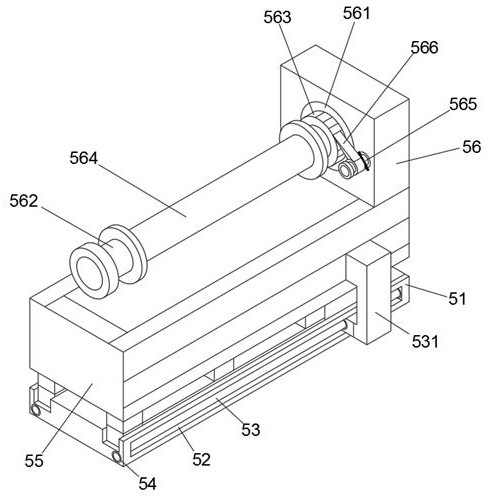

[0022] Example. Please refer to Figure 1-3 , a power cable drawing machine with uniform wire drawing, including a first connection box 1, a first cavity 11 and a second cavity 12 are arranged in the first connection box 1, and a Drawing structure 2, the second cavity 12 is provided with a constant temperature water cooling structure 3, cables run through the first cavity 11 and the second cavity 12, and the outside of the first connection box 1 is provided with a plurality of transmission wheels 4. One end of the plurality of transmission wheels 4 is connected to the automatic winding device 5 through cable transmission.

[0023] Example. Please refer to figure 1 The drawing structure 2 includes two first drive motors 21, the two first drive motors 21 are detachably connected to the bottom of the first cavity 11, and the drive shafts of the two first drive motors 21 are connected to the second A rotating rod 22, the first rotating rod 22 is detachably connected to the tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com