Blowing device of metal 3D printer

A 3D printer and blower technology, applied in the field of 3D printing, can solve the problems of difficulty in ensuring fluid uniformity and laminar flow, weakening the laminar flow of the protective gas on the surface of the powder bed, and affecting the quality of the molding surface, so as to reduce eddy current and ensure The effect of smooth blending and laminar flow improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The blowing device provided by the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

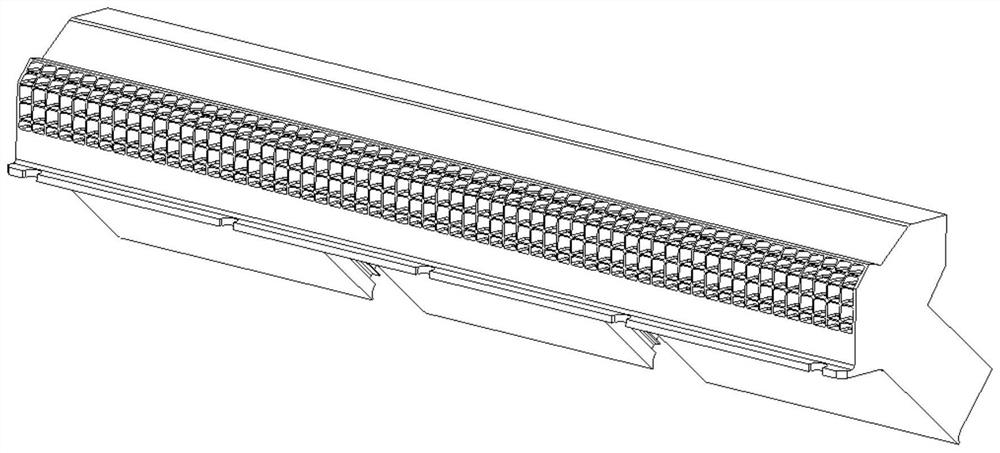

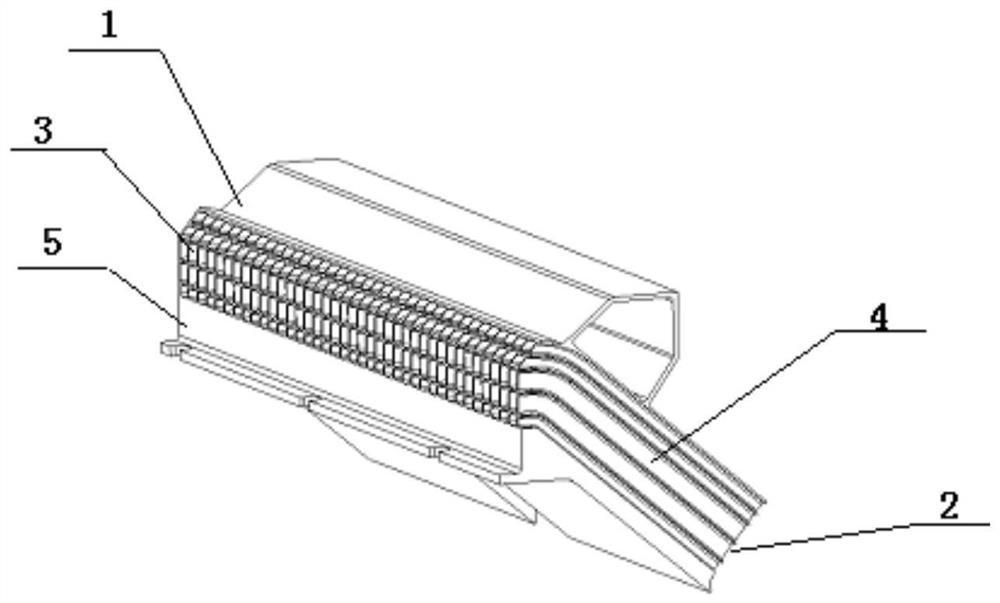

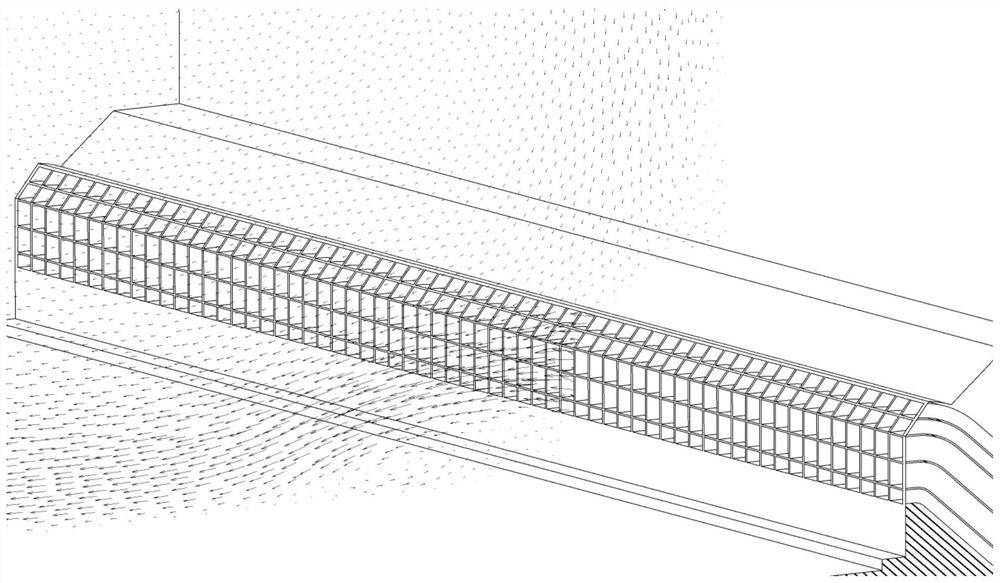

[0029] see Figure 4 , Figure 5 as well as Image 6 , the present invention provides a metal 3D printer blowing device, which is the same as the prior art: the blowing structure includes a casing 1, and the casing 1 is provided with an air inlet 2 and an air outlet 3; the inside of the casing 1 is provided with Airflow channel 4; airflow channel 4 includes N layers of flow channels superimposed sequentially from top to bottom; N≥2; air inlet 2 communicates with air outlet 3 through airflow channel 4; the lower edge of air outlet 3 and the lower edge of housing 1 There is a baffle plate 5 with a height h between them; the difference from the prior art is that the baffle plate 5 is provided with a bottom flow channel outlet 6, and the bottom flow channel 9 in the air flow channel 4 communicates with the bottom fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com