Method and apparatus for additive manufacturing

A technology of additive manufacturing and equipment, applied in the direction of additive processing, processing and manufacturing, manufacturing tools, etc., can solve the problems of low productivity and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

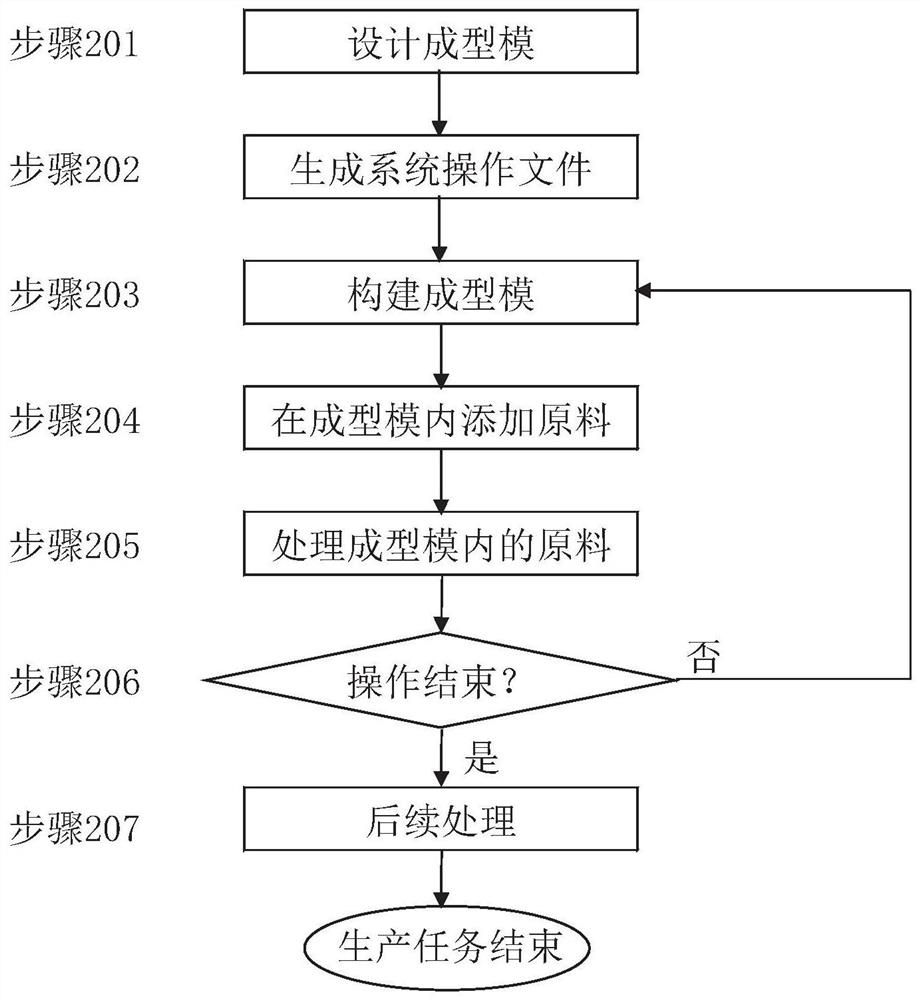

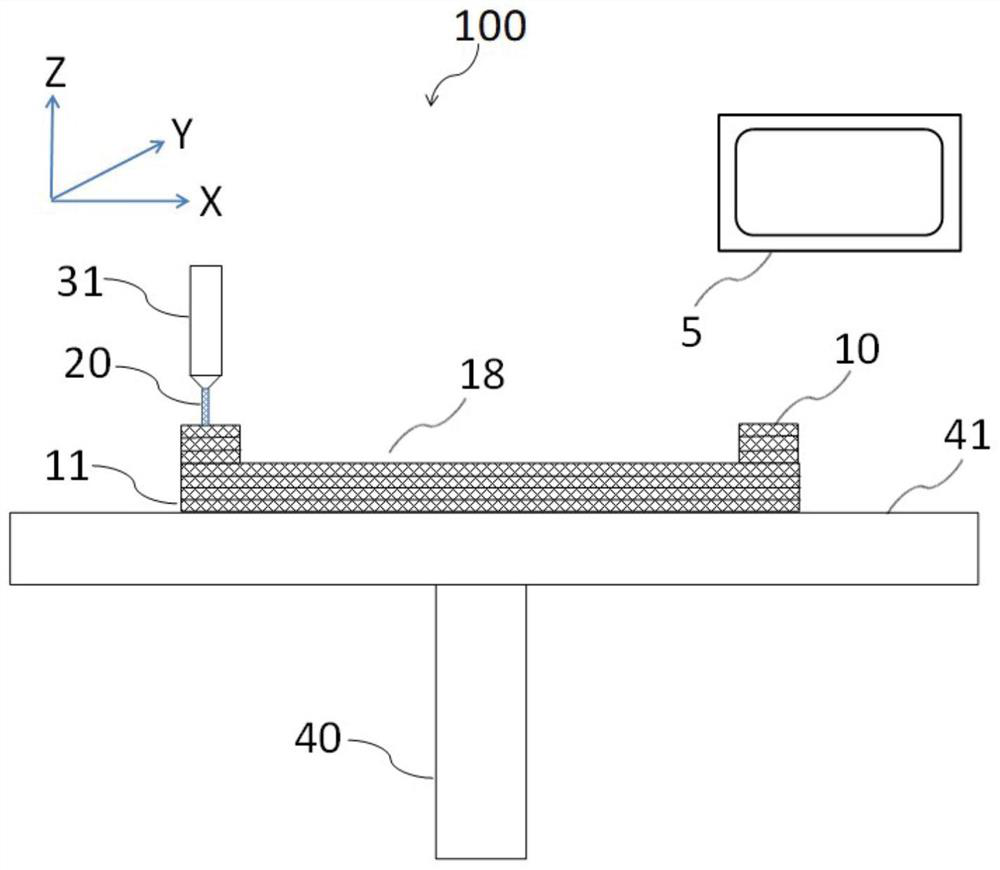

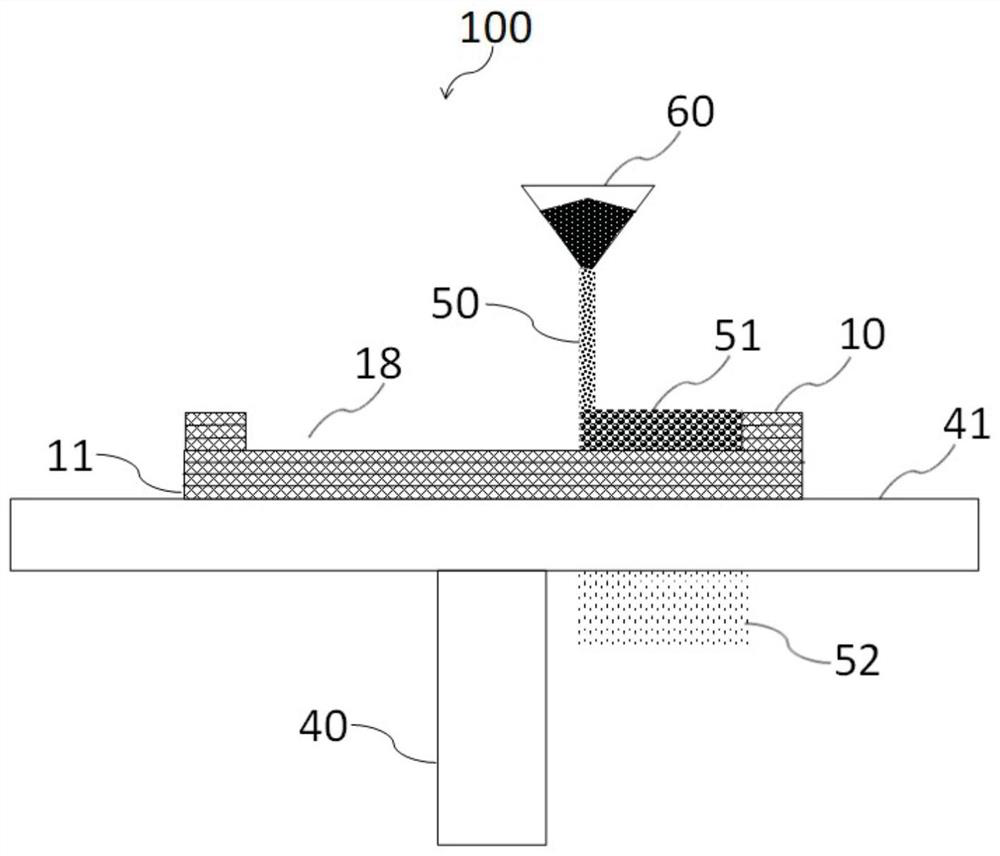

[0017] The present invention generally relates to a method and equipment for additive manufacturing of a three-dimensional object. The method and equipment are configured to construct a forming mold layer by layer through a set of geometric shapes corresponding to a set of cross-sections, and to provide raw materials to the interior for processing. To shape the three-dimensional object. The forming mold or part of the forming mold presents a closed-around structure during its construction, and thus has a cavity formed therein, which can be used to shape a three-dimensional object with an outer surface and an inner surface. In this way, after at least one layer is built up in the forming mold, raw materials can be added to it for processing. The construction of the forming mold and the object continues until the construction of the three-dimensional object is completed.

[0018] The molding die is more suitable for building a thin-walled shell-shaped structure to reduce the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com