Additive-manufactured porous tantalum metal acetabular outer cup and preparation method thereof

An additive manufacturing, porous tantalum technology, applied in metal processing equipment, manufacturing tools, acetabular sockets, etc., can solve the problems of prosthesis loosening, high strength and modulus, and limited rough treatment layer thickness, and achieve limb restoration. function, improve joint function, restore stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

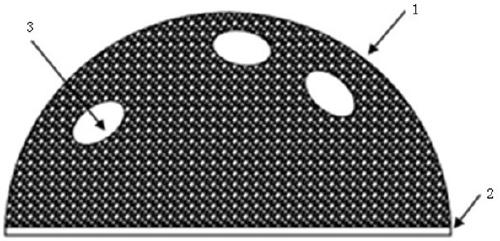

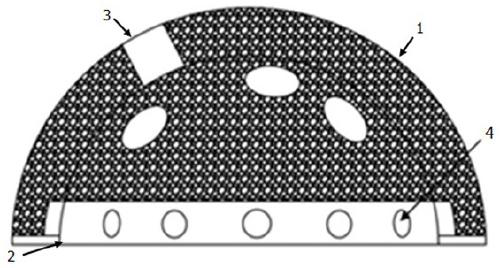

[0037] Example 1 Biomimetic Acetabular Outer Cup with Porous Trabecular Bone Structure

[0038] like Figure 1-4 As shown, the acetabular outer cup in this embodiment is composed of a dense structure cup mouth 2 and a bionic bone trabecular porous structure hemispherical shell cup body 1, wherein the average wire diameter of the porous structure is 298 μm, and the average pore diameter is 878 μm; the porosity is 75.1%, and the pores are connected. Sex is 99%. The outer height of the cup mouth is 1mm, and the inner height is 5mm; the inside of the cup mouth is evenly distributed along the circumference of 10 cylindrical slots 4, the slot diameter is 3mm, and the depth is 1mm; the cup body of the porous structure hemispherical shell is provided with 7 through screw holes 3 , the inner wall of the screw hole is a dense layer with a thickness of 1mm; the diameter of the screw hole is 5mm.

[0039] The manufacturing steps of the bionic bone trabecular porous structure acetabular ...

Embodiment 2

[0049] Example 2 Rhombohedral acetabular cup with porous structure

[0050] like Figure 5-8 As shown, the acetabular outer cup of this embodiment is composed of a rhomboid dodecahedron porous structure hemispherical shell cup body 1, wherein the average wire diameter of the porous structure is 413 μm, the average pore diameter is 835 μm; the porosity is 70%, and the pore connectivity is 99%. The cup body of the porous structure hemispherical shell is provided with 4 through screw holes 3 , the inner wall of the screw holes is a dense layer with a thickness of 1 mm; the diameter of the screw holes is 5 mm.

[0051] The manufacturing steps of the rhombic dodecahedron porous structure acetabular outer cup are as follows:

[0052] Using modeling software to construct the three-dimensional model of the acetabular outer cup of the bionic trabecular porous structure, convert the three-dimensional model into the format required by the printing equipment and import it into the equipm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com