Intelligent slitting system and process for fiberglass tube

A glass fiber tube, an intelligent technology, applied in metal processing and other directions, can solve the problems of using influence, adjusting the running state of the cutting mechanism, and unable to automatically adjust the distance of the cutting blade, so as to avoid the loss of power transmission and the effect of avoiding pinching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

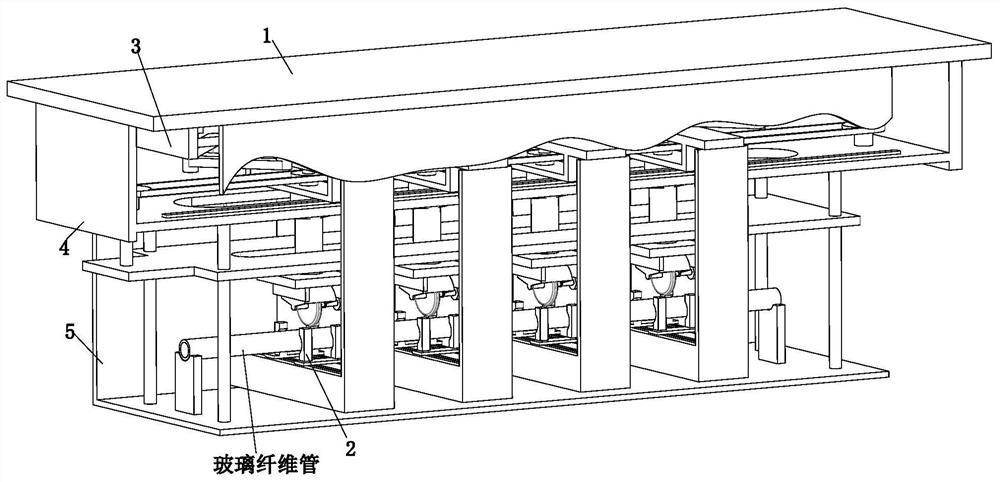

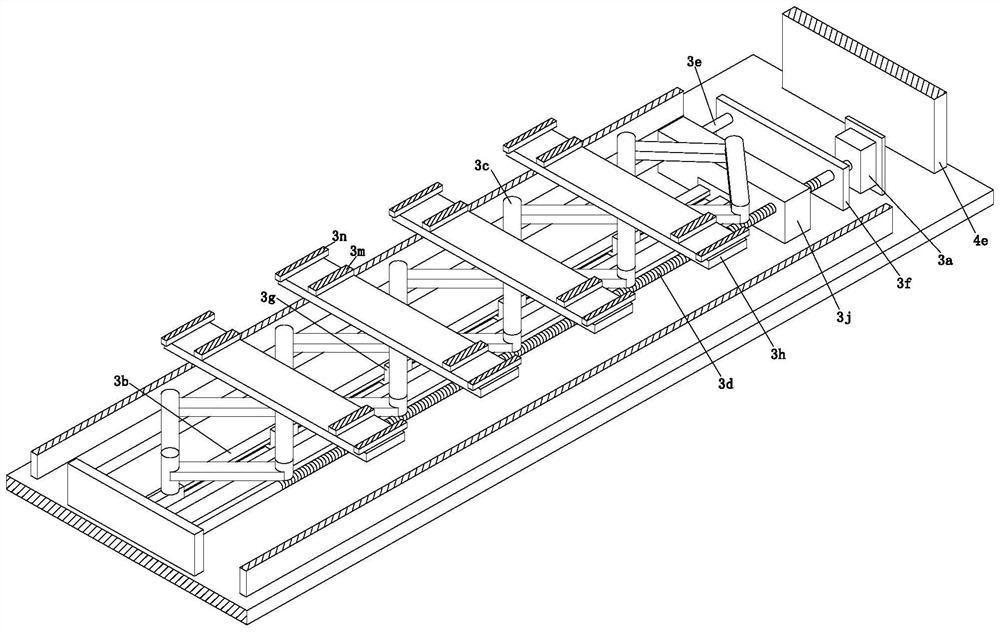

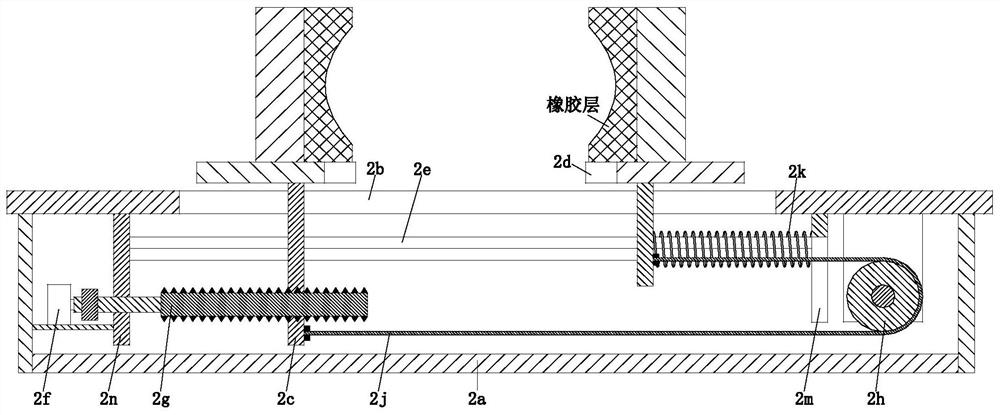

[0027] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 9 , to further elaborate the present invention.

[0028] An intelligent slitting system for glass fiber tubes, comprising an installation base plate 1, a clamping mechanism 2, a distance adjustment mechanism 3, a cutting mechanism 4, and a support frame 5, the lower end of the installation base plate 1 is equipped with an upwardly opening support frame Frame 5, the distance adjustment mechanism 3 is installed on the installation base plate 1 on the inner side of the support frame 5 through sliding fit, the distance adjustment mechanism 3 is equipped with a cutting mechanism 4, and the distance adjustment mechanism 3 below the cutting mechanism 4 is evenly installed with Clamping mechanism 2.

[0029] Described distance adjustment mechanism 3 comprises distance adjustment motor 3a, chute frame 3b, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com