In-mold labeling material taking and conveying manipulator and in-mold labeling and telescopic material receiving equipment set

A technology of in-mold labeling and manipulators, applied to household components, household appliances, and other household appliances, can solve the problems of slow efficiency and achieve the effect of reducing equipment costs and increasing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

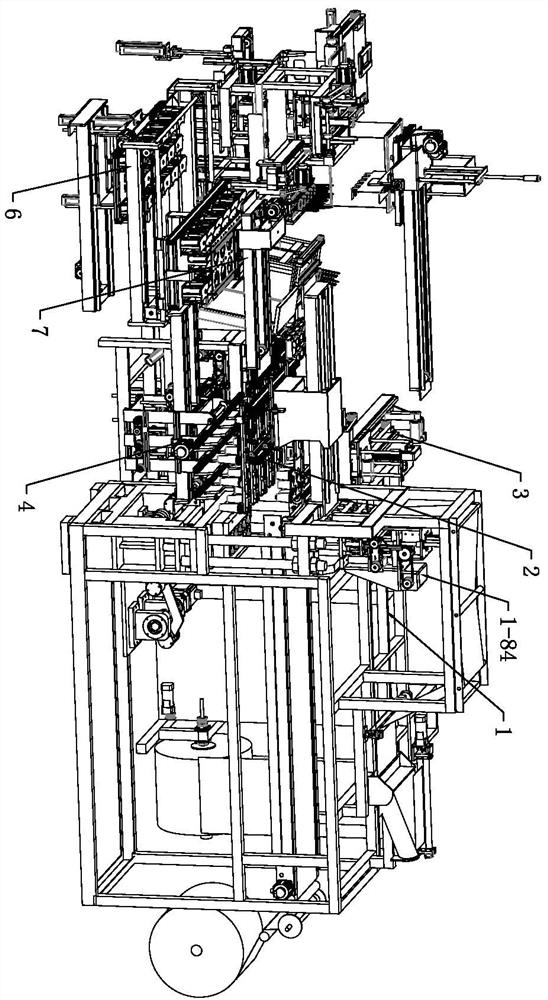

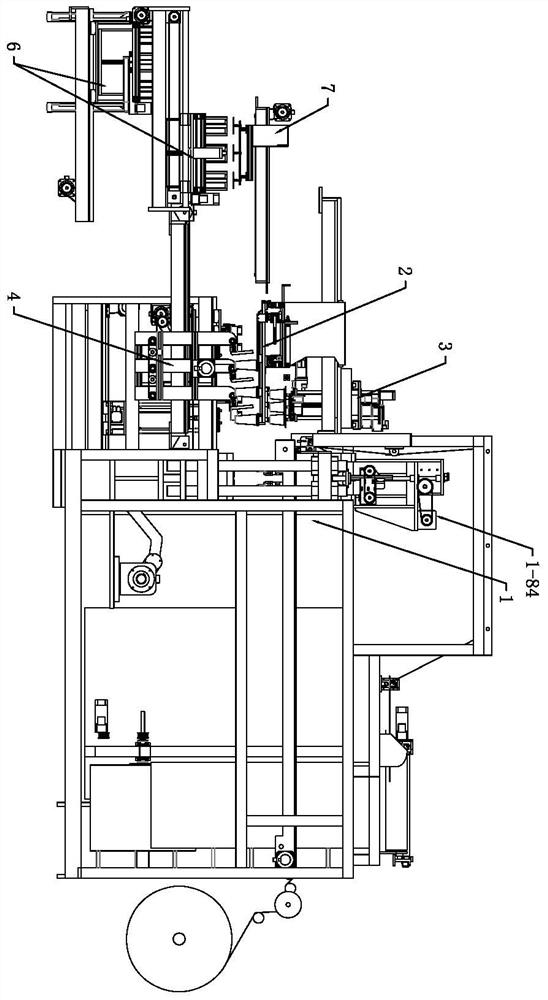

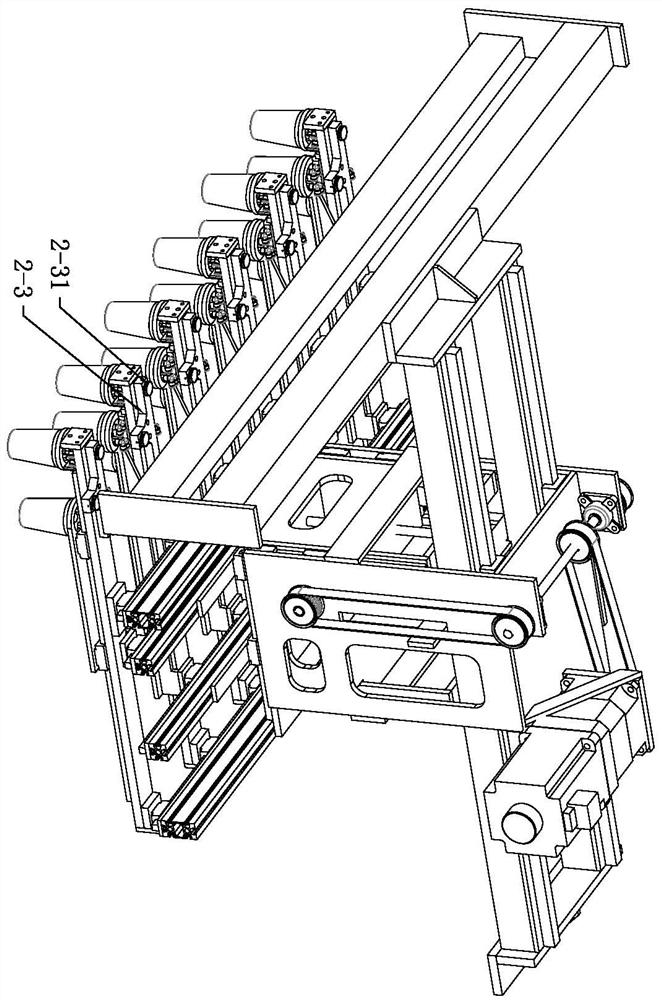

[0081] see Figure 1 to Figure 6In this embodiment, the in-mold labeling, retrieving, and conveying manipulator 2 includes a manipulator bracket 2-4, a support seat 2-5, a translation drive device, a telescopic drive for row spacing, and a telescopic drive for row spacing. The bottom of the support seat 2-5 is equipped with The row-spacing support member is fixed, and the support seat 2-5 is installed on the manipulator support 2-4, and the translation drive device 2-41 drives the support seat 2-5 to translate. The bottom of the support seat 2-5 is equipped with a fixed support frame 2-61 and a fixed support frame 2-62 for sliding in the front distance, between the fixed support frame 2-61 for sliding in the front distance and the fixed support frame 2-62 for sliding in the rear distance. There are multiple single-row multi-row sliding support frames 2-63 arranged between them, and multiple single-row multi-row sliding support frames 2-63 are slid on the support seat 2-5 throu...

Embodiment 2

[0093] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. see Figure 13 In this embodiment, the lifting driving device includes a motor 1-84, a gear, a lifting rack 1-85, a rack support guide rail 1-86 and a slider 1-87, and the slider 1-87 is fixed on the bracket 1-88, the rack support guide rail 1-86 is slidably installed on the slider 1-87, the pulling rack 1-85 is installed on the rack support guide rail 1-86 and the lower end is connected with the cross arm 1-81, The motor drives a gear to rotate, and the gear is engaged with the lifting rack for transmission.

Embodiment 3

[0095] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. In this embodiment, the line spacing telescopic drive of the in-mold labeling, pick-up, and transfer manipulator is composed of a motor, a transmission assembly, and a two-way screw rod. Connected, the two-way screw is driven by the motor to rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com