Roller type bagging and opening holding device

A bagging and roller-type technology, applied in the field of packaging machine equipment, can solve problems such as single function, complex control logic structure, and high accuracy requirements for operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

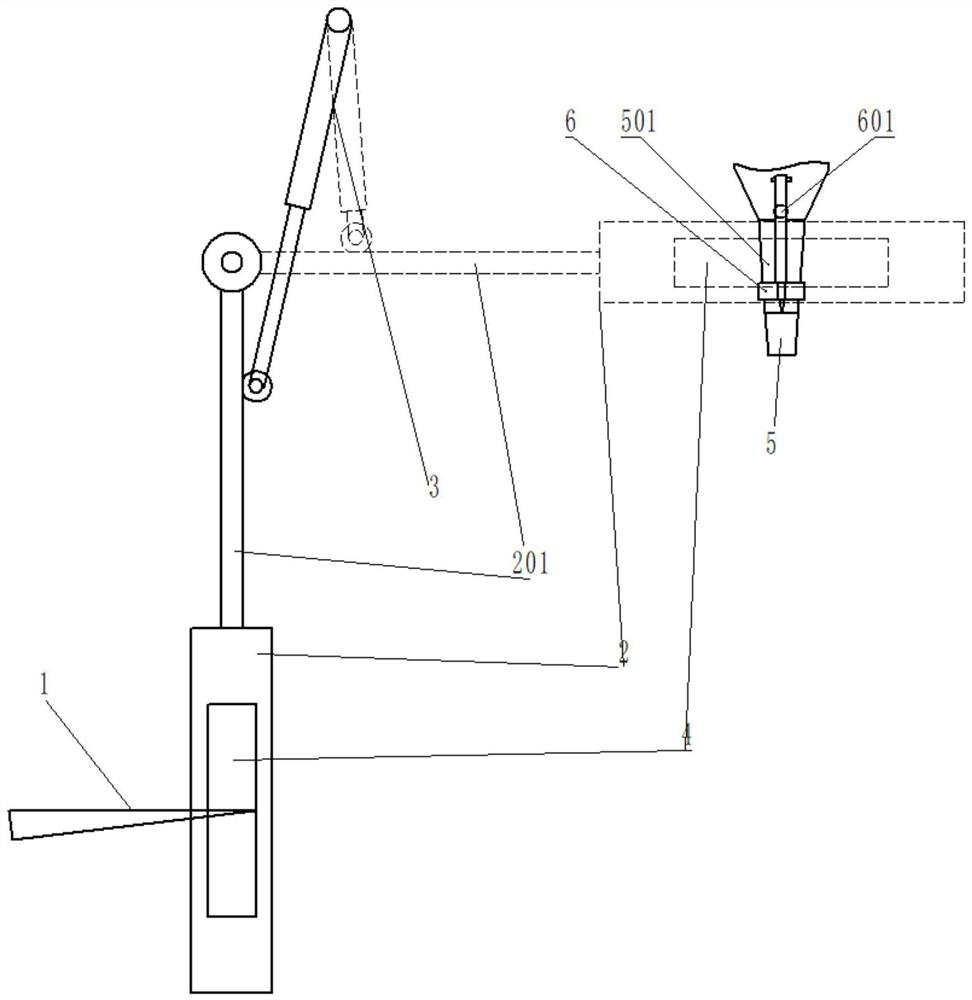

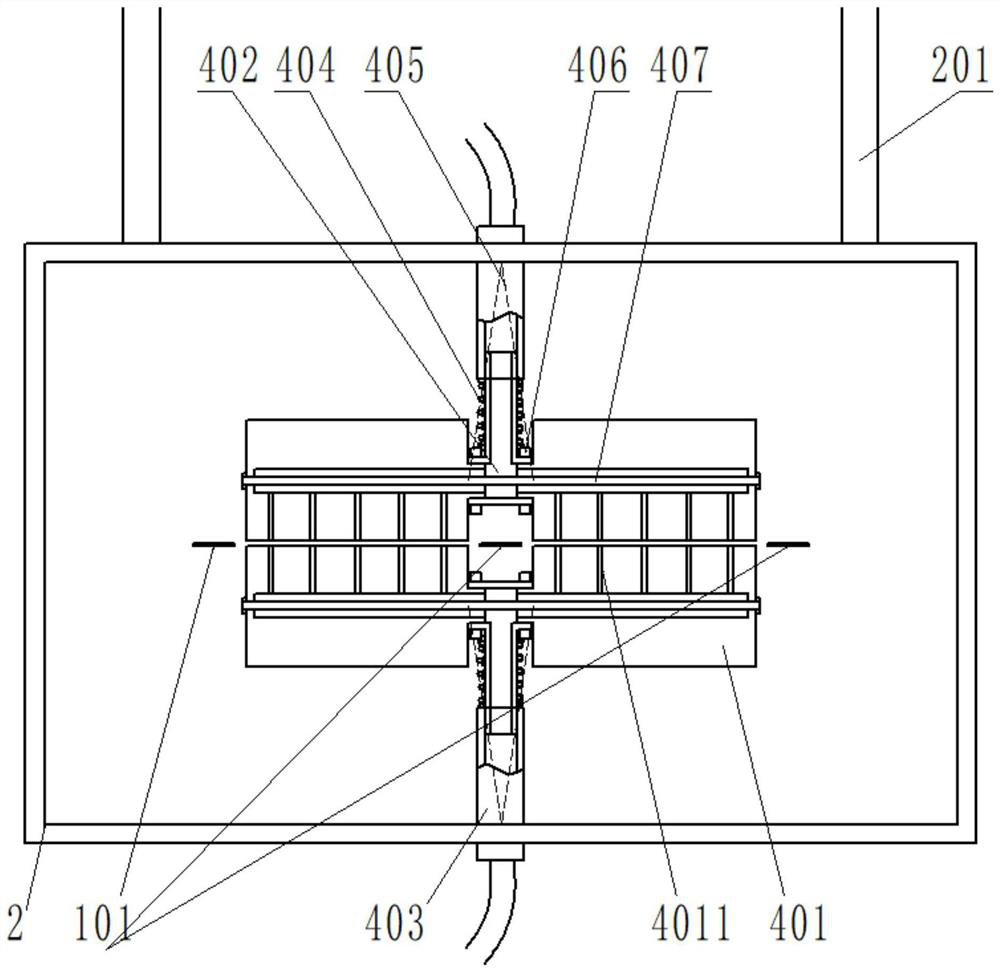

[0024] Roller bagging mouth holding device, including bag conveying table 1, bagging roller frame 2, roller frame driving piston 3, bagging roller mechanism 4, edge feeding port 5, V-shaped mouth holding device 6; among them, bagging The roller frame 2 is hinged on the frame through the roller frame connecting rod 201, and the roller frame driving piston 3 is installed between the roller frame connecting rod 201 and the frame, and the bagging roller frame 2 is driven to reciprocate by the roller frame driving piston 3. One end is located below the hinge point of the roller frame connecting rod 201, and the bag delivery platform 1 passes through the bagging roller frame 2 at this position, and the other end of its stroke is located on the horizontal side of the roller frame connecting rod 201 hinge point, and the edge feeding port 5 is at This location passes through the bagging roll stand 2 .

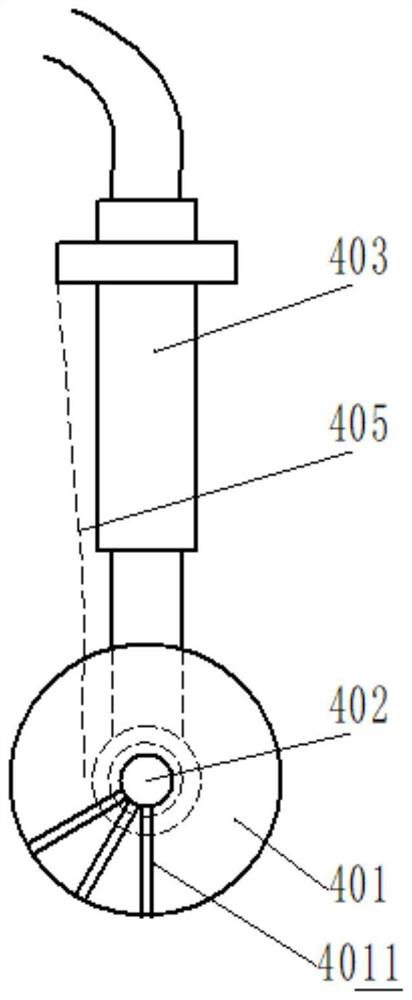

[0025] The bagging roller frame 2 is a hollow frame, and two bagging stick mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com