A water level pressure grouting sealing method

A technology of water level pressure and water level, applied in construction, infrastructure engineering, protection devices, etc., can solve the problems of high plugging requirements, poor flexibility, and high cost, and achieve the effects of construction cost guarantee, convenient material acquisition, and rapid response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

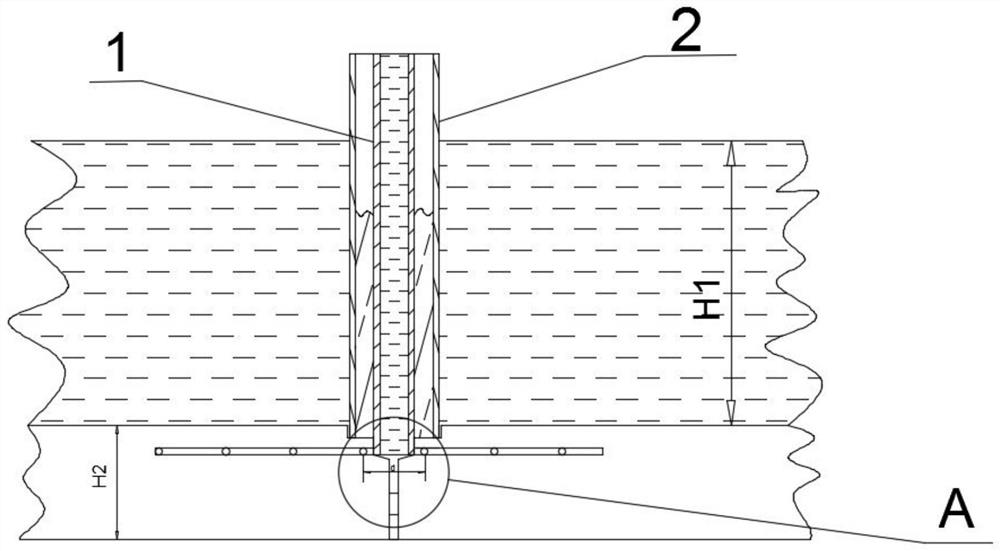

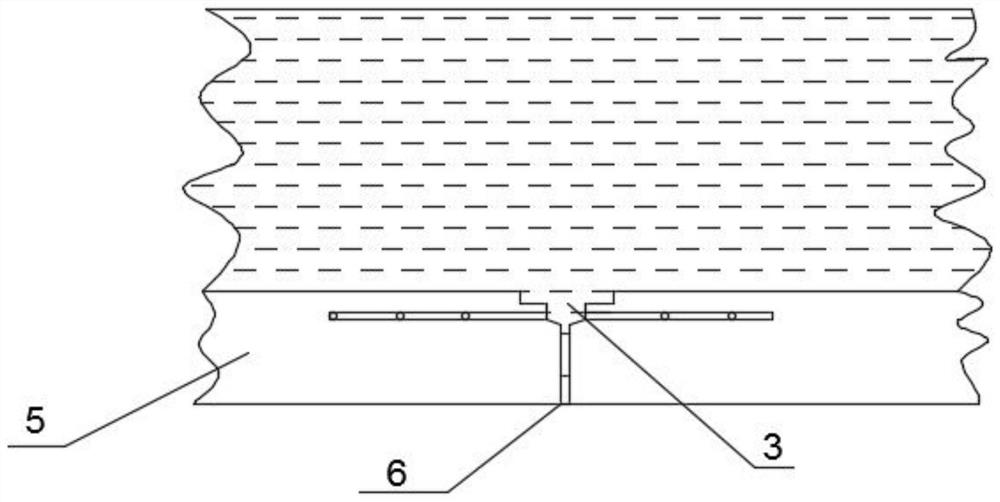

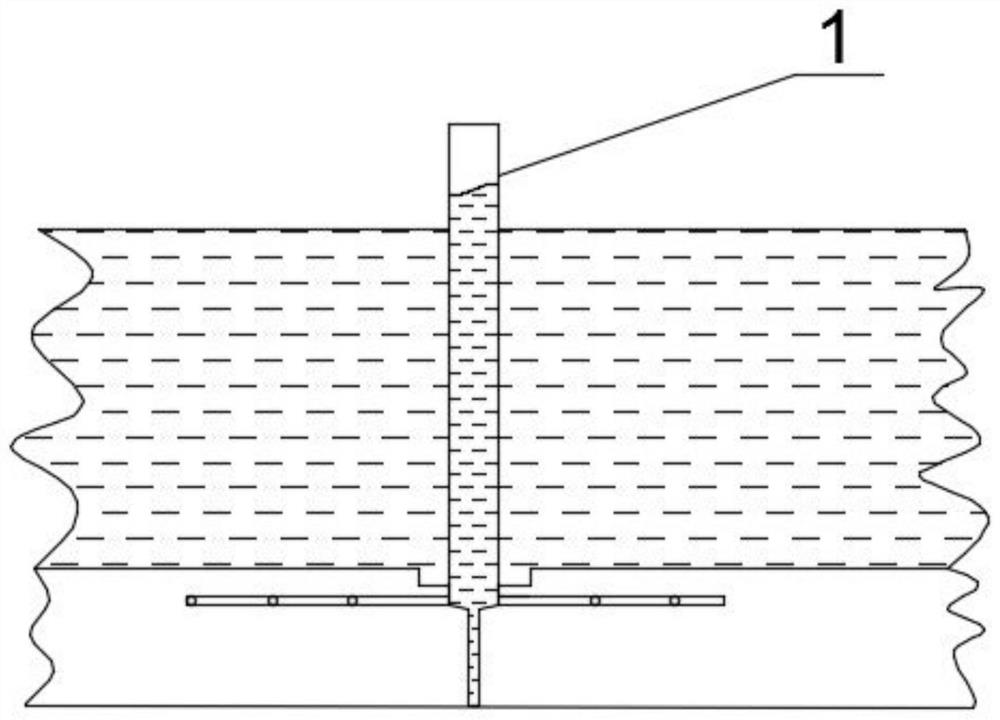

[0058] Such as Figure 1 to Figure 6 Shown: a water level pressure grouting plugging method, including a water leakage port 6, a cylinder 1, a cylinder 2 2 and a plugging piece 4, the diameter of the cylinder 1 is smaller than the diameter of the cylinder 2,

[0059] Also includes the following steps:

[0060] Step 1: Cut out the regular water leak 6, including:

[0061]1) Determine the water leak 6 of the bottom plate 5 to be blocked, excavate the concrete until the steel bars on the surface of the bottom plate 5 are exposed, and expand to a circular shallow pit 3 that is larger than the diameter of the cylinder 2 around the water leak 6;

[0062] 2) Control the bottom of the circular shallow pit 3 to be stepped, the circular shallow pit 3 includes a first stepped hole and a second stepped hole, the first stepped hole is located on the second stepped hole, and the diameter of the first stepped hole is larger than that of the cylinder two 2, the diameter of the second steppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com