Novel composite wall

A composite wall, a new type of technology, applied in the direction of walls, formwork/formwork/work frame connectors, formwork/formwork/work frame, etc., can solve the problem that the pull bolts cannot be uniformly stressed, the installation process is cumbersome, and cannot Effectively ensure the precise distance between the templates on both sides, etc., to achieve the effects of improving production efficiency, convenient installation, reducing the number of holes and cold bridge points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

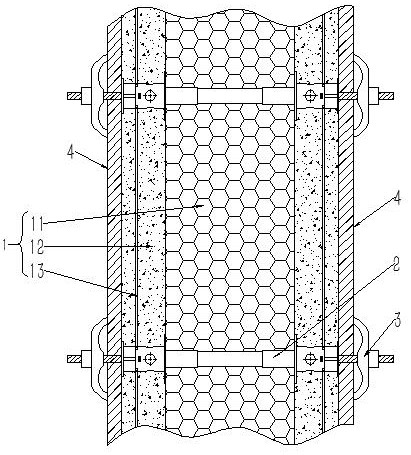

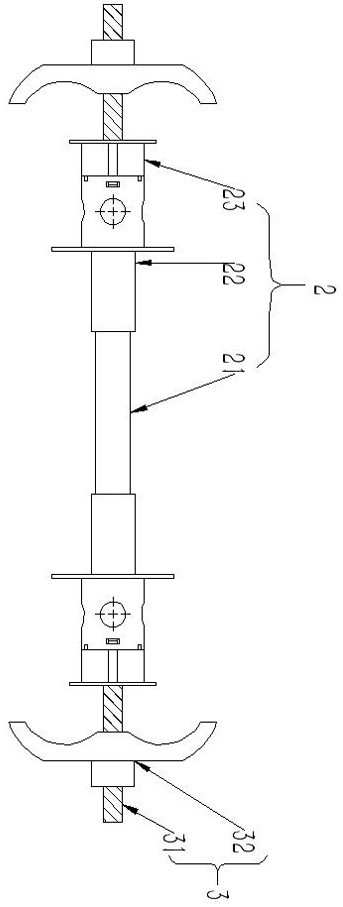

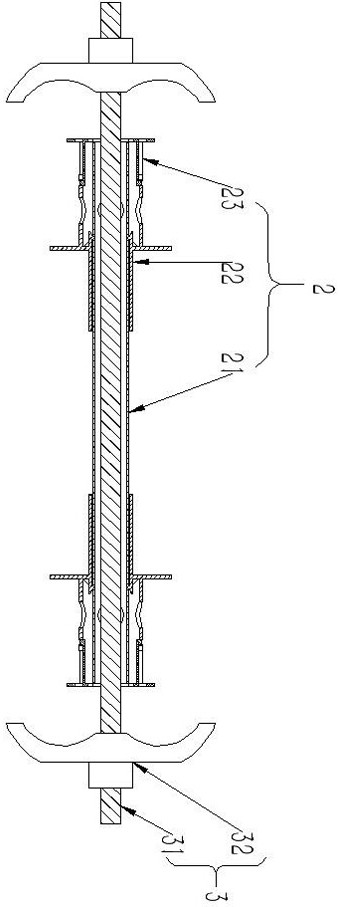

[0023] Such as Figure 1-Figure 3 Commonly shown, the present invention provides a new type of composite wall, including a composite thermal insulation wall body 1 and a fixed connection integrated part 2, the fixed connection integrated part 2 runs through the composite thermal insulation wall body 1; the fixed connection integrated part 2 It is a hollow structure.

[0024] The composite thermal insulation wall body 1 includes a composite thermal insulation board 11, the two sides of the composite thermal insulation board 11 are respectively provided with a concrete layer 12, and the inside of the concrete layer 12 is provided with a steel wire mesh sheet 13; the composite thermal insulation board 11 can , choose a single-layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com