Magneto-rheological torsion damper

A torsional shock absorber and magneto-rheological fluid technology, which is applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problem of non-adjustable damping of torsional shock absorbers, and achieve stable work and precise control , Viscosity has little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be described in detail below through specific examples.

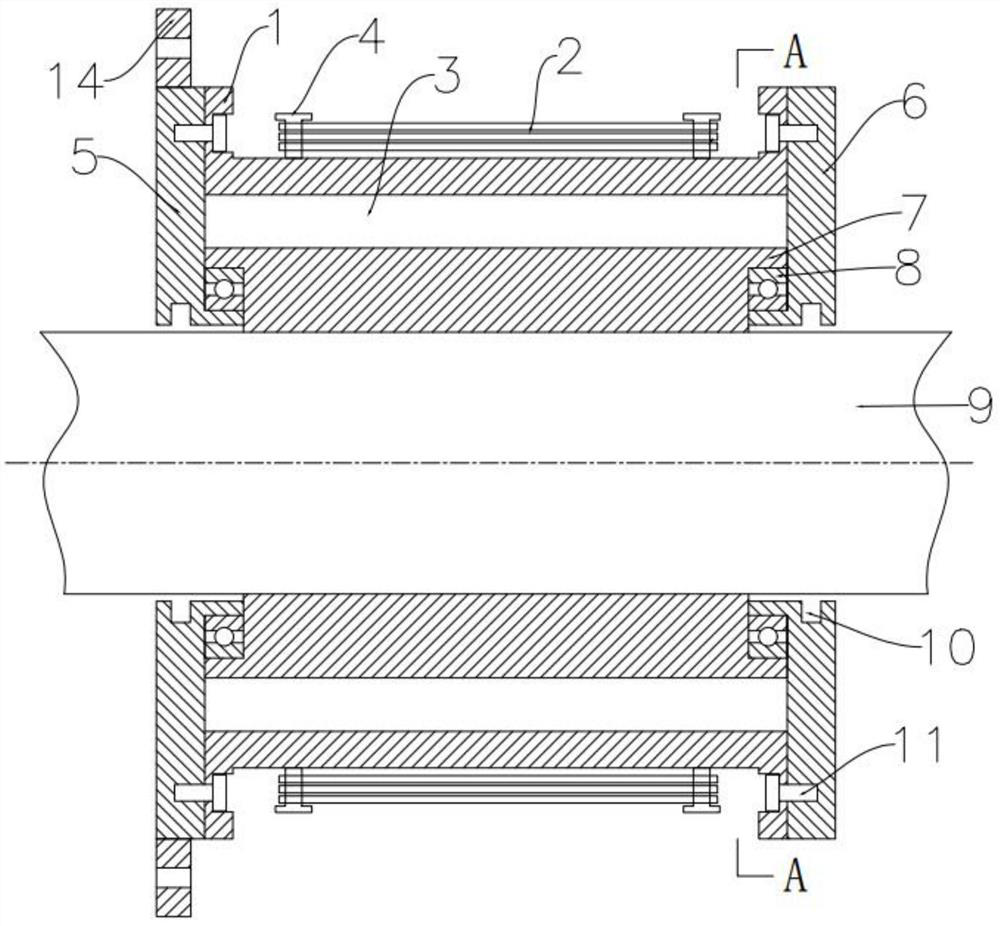

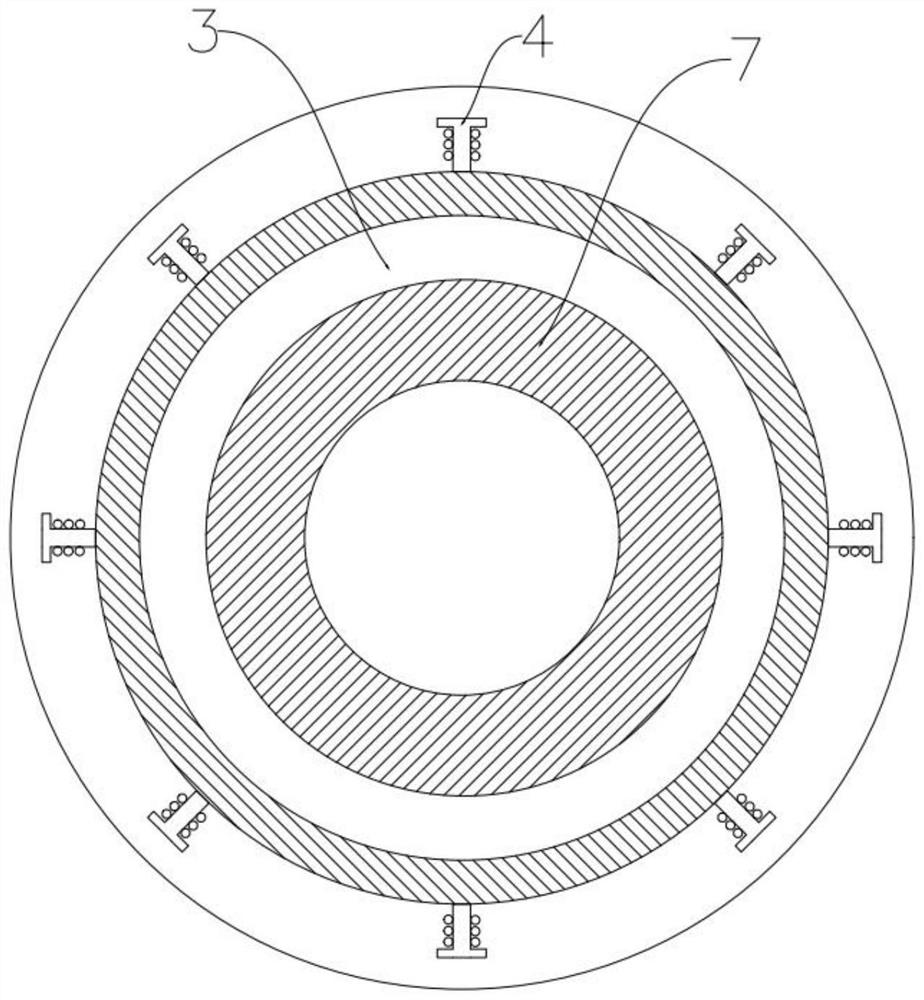

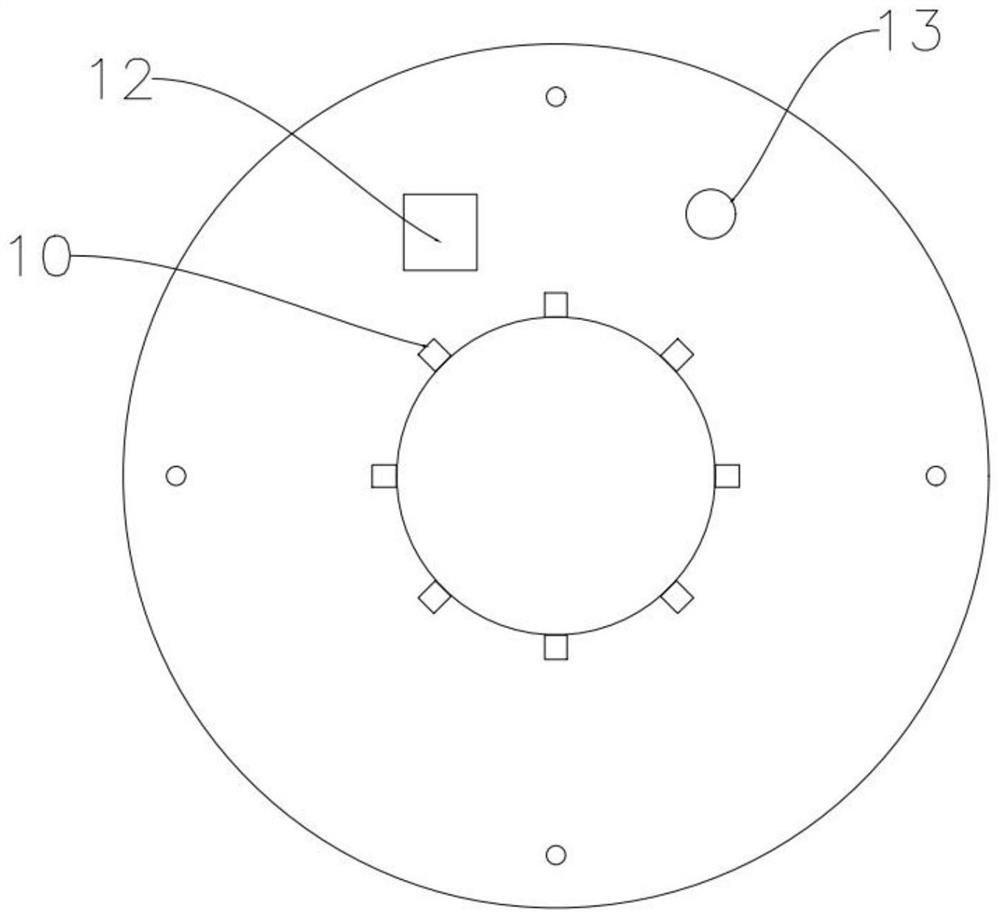

[0026] Such as Figure 1 to Figure 6 As shown, it includes a shell 1, a rear end cover 5, a front end cover 6, and an inner sleeve 7. The rear end cover 5 and the front end cover 6 are detachably connected to the shell 1, and the shell 1 is provided with a winding A wire rod 4, an electromagnetic coil 2 is wound on the wire winding rod 4, a distance sensor 11 is installed on the rear end cover 5 and the front end cover 6, and a reserved hole for the transmission shaft 9 is provided in the middle, so A controller 12 and a power interface 13 are fixed on the front end cover 6, the inner sleeve 7 is installed between the rear end cover 5 and the front end cover 6, the inner sleeve 7 and the rear end cover 5 and the front end cover 6 is installed with a bearing 8, the middle of the inner sleeve 7 is provided with a through hole for the drive shaft 9 to pass throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com