Efficient drying device for tea processing

A drying device and high-efficiency technology, applied in the direction of tea drying, drying, drying machine, etc., can solve the problems of poor gas fluidity, output, unfavorable tea drying, etc., to improve work efficiency, high work speed, and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

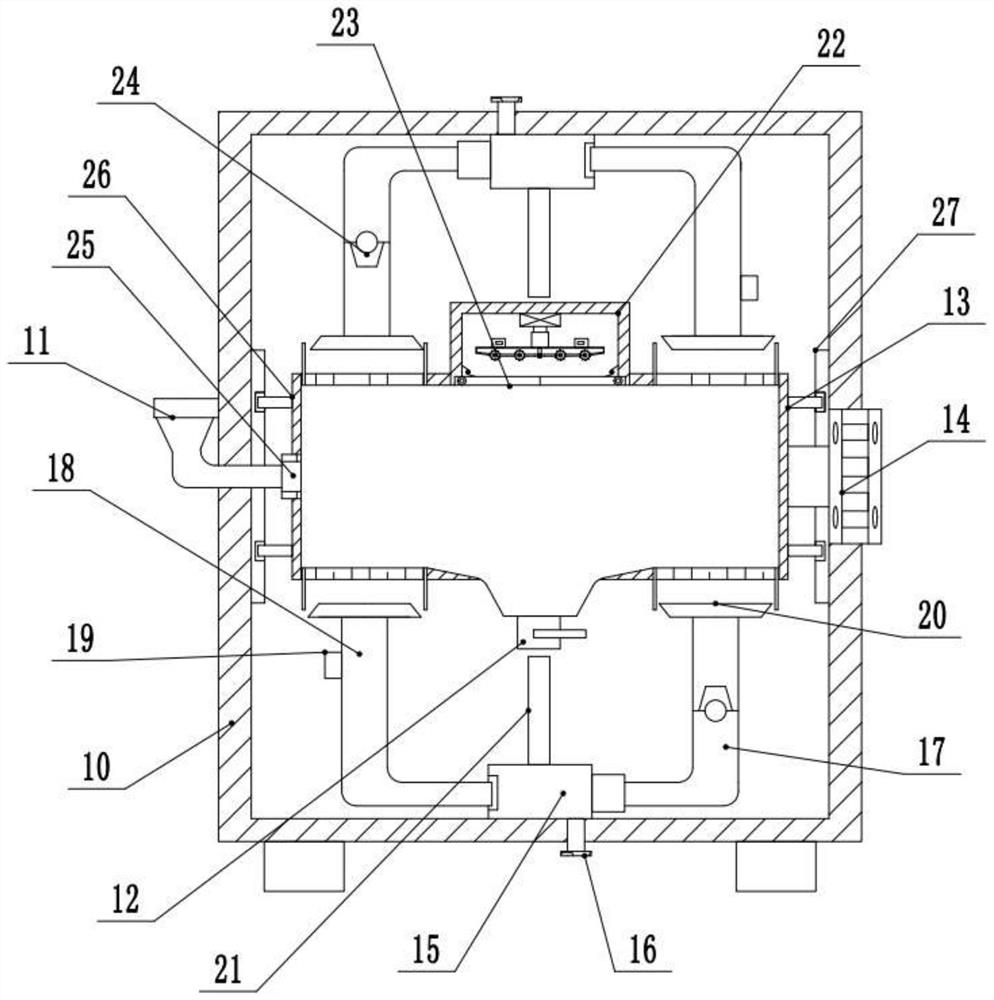

[0020] see Figure 1-2 , a high-efficiency drying device for tea processing, comprising a box body 10, a feed port 11, and a material outlet port 12; the left and right sides of the bottom of the box body 10 are fixedly supported by brackets, and the inner center of the box body 10 is provided with a A set of horizontal drying cylinders 13, the bottom middle of the drying cylinder 13 is provided with a discharge port 12 downward, and the middle part of the left side wall of the drying cylinder 13 is connected to the outside through the rotating communication valve 25. The end of the L-shaped structure extends to The feed port 11 on the outside of the left side wall of the box body 10, and the top of the feed port 11 is provided with a trumpet-shaped structure that facilitates feeding. The left and right side walls of the drying cylinder 13 are fixed symmetrically and fixedly installed with a rotating track 26. The rotating track 26 is rotatably connected to the chute opened in...

Embodiment 2

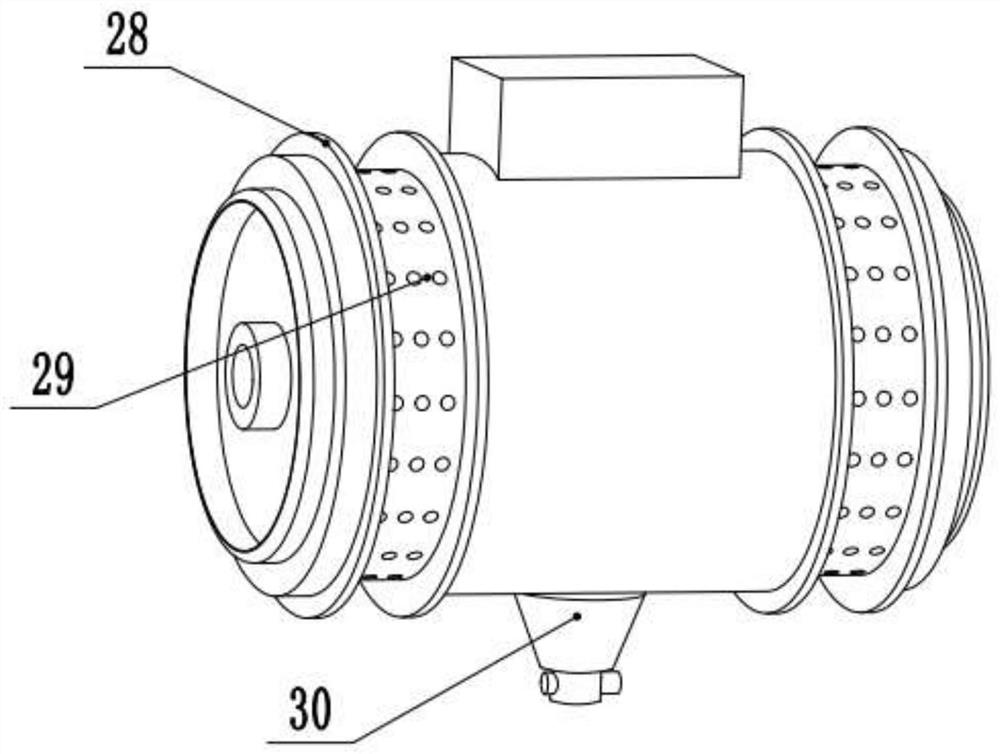

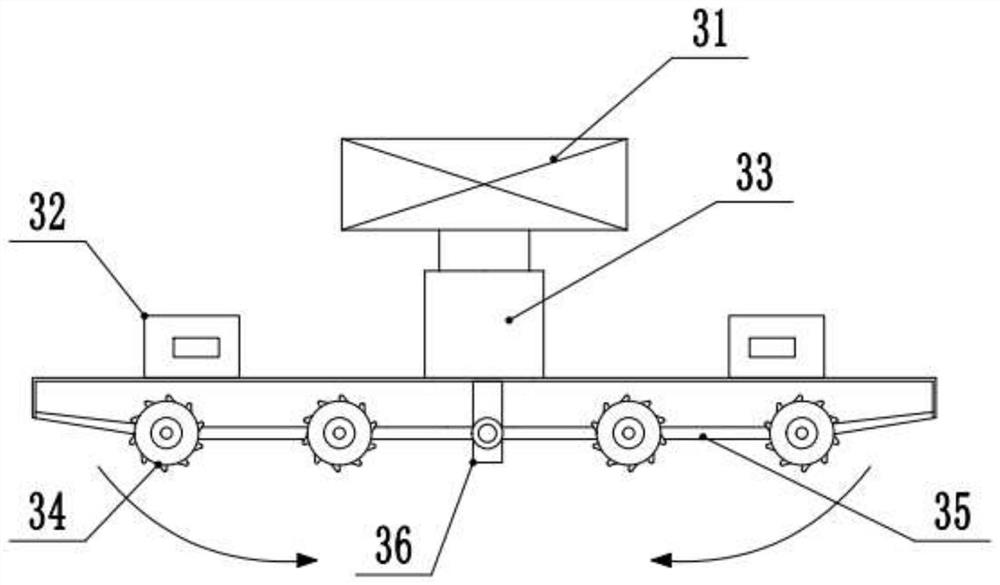

[0022] see image 3, on the basis of the first embodiment, the inside of the drying cylinder 13 at the top of the discharge port 12 is connected downward with a funnel-shaped feeding channel 30, and the feeding channel 30 is convenient for the tea leaves inside the drying cylinder 13 to pass through. It flows into the feed channel 30 under the action of gravity. A set of discharge cavities 22 are fixedly installed in the middle of the outer top of the drying cylinder 13, and a set of elevators 31 are fixedly installed on the inner top of the discharge cavity 22. The bottom of 33 is fixedly installed with a set of mounting frames, and the tops of the left and right sides of the mounting frame are fixedly provided with two sets of driving devices 32 with opposite directions of rotation. , The feeding rollers 34 are connected in rotation by the transmission belt 35, and the left and right feeding rollers 34 are separated from each other by the connecting plate 36 fixed at the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com