Composition for forming organic film, patterning process, and polymer

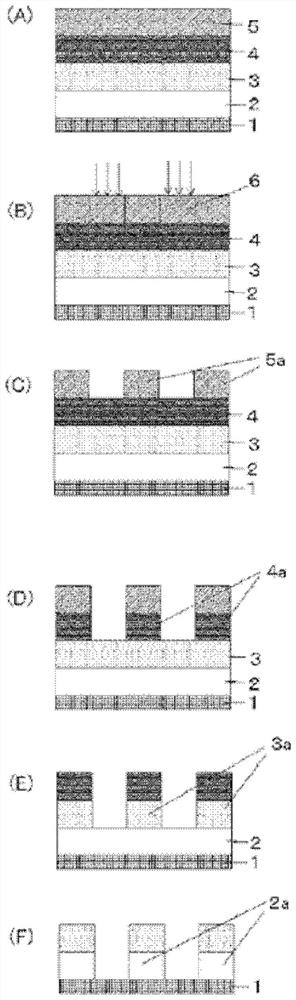

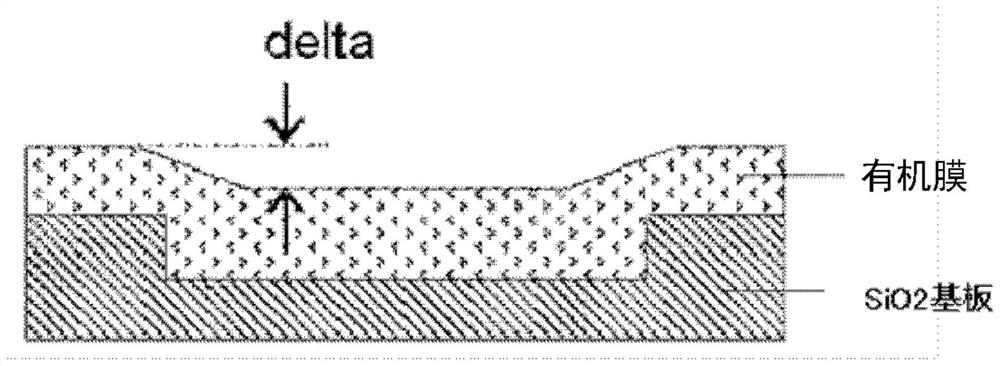

A technology of organic film and composition, which is applied in the direction of photomechanical equipment, photoplate process of pattern surface, photosensitive material used in optomechanical equipment, etc., which can solve the problem of organic film heat resistance and damage to etching resistance And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0257] Hereinafter, the present invention will be more specifically described with reference to synthesis examples, comparative synthesis examples, examples, and comparative examples, but the present invention is not limited to these descriptions. In addition, the weight average molecular weight (Mw) and the number average molecular weight (Mn) in terms of polystyrene were obtained by gel permeation chromatography (GPC) using tetrahydrofuran (THF) as a developing solvent, and the degree of dispersion (Mw / Mn) was calculated. ).

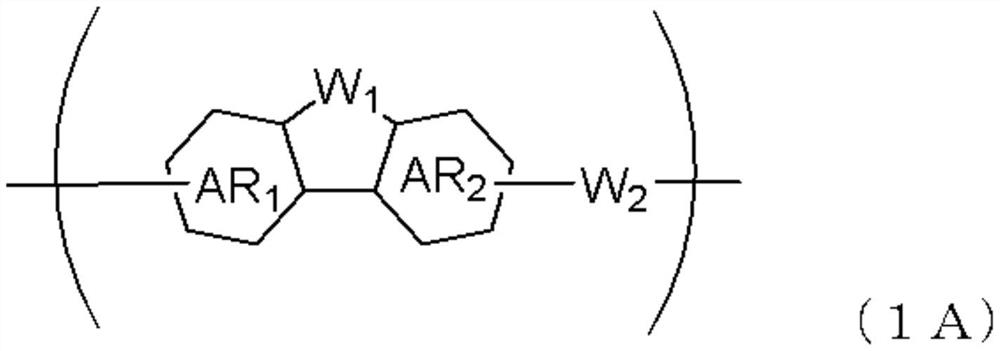

[0258] Synthesis of the polymers (A1) to (A12) contained in the composition for forming an organic film uses the following fluorenes: (B1) to (B5), ketones, aldehydes, tertiary alcohols: (C1) to ( C11).

[0259] Fluorenes:

[0260] [chemical 40]

[0261]

[0262] Ketones, aldehydes, tertiary alcohols:

[0263] [chem 41]

[0264]

[0265] When synthesizing a polymer having a plurality of substituents, the ratio is expressed using m, 1 in the ...

Synthetic example 1

[0269] Under nitrogen atmosphere, 50.0g of compound (B1), 43.8g of compound (C1), 3.2g of 3-mercaptopropionic acid and 400g of 1,2-dichloroethane were made into a uniform solution at an internal temperature of 70°C, and then slowly 28.9 g of methanesulfonic acid was added, and the reaction was carried out at an internal temperature of 70° C. for 24 hours. After cooling to room temperature, 1000 g of toluene was added, the organic layer was washed with 300 g of pure water six times, and the organic layer was dried under reduced pressure. 300 g of THF was added to the residue to form a uniform solution, and then the polymer was reprecipitated with 1000 g of methanol. The precipitated polymer was separated by filtration, washed twice with 600 g of methanol, and recovered. The recovered polymer was vacuum dried at 70°C to obtain (A1). The weight-average molecular weight (Mw) and degree of dispersion (Mw / Mn) of the polymer (A1) obtained using the polystyrene conversion value obta...

Synthetic example 2

[0273] Under nitrogen atmosphere, 50.0g of compound (B3), 22.6g of compound (C2), 2.2g of 3-mercaptopropionic acid and 400g of 1,2-dichloroethane were made into a uniform solution at an internal temperature of 70°C, and then slowly 19.8 g of methanesulfonic acid was added and reacted at an internal temperature of 70° C. for 24 hours. After cooling to room temperature, 1000 g of toluene was added, the organic layer was washed with 300 g of pure water six times, and the organic layer was dried under reduced pressure. 300 g of THF was added to the residue to form a uniform solution, and then the polymer was reprecipitated with 1000 g of methanol. The precipitated polymer was separated by filtration, washed twice with 600 g of methanol, and recovered. The recovered polymer was vacuum-dried at 70°C to obtain (A2). The weight-average molecular weight (Mw) and degree of dispersion (Mw / Mn) were determined by GPC and found to be Mw=3440 and Mw / Mn=3.23.

[0274] [chem 44]

[0275] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com