Online forecasting method for linear defects at edge of hot-rolled strip steel

A technology for linear defects and hot-rolled strip steel, which is applied in the field of intelligent online prediction of edge linear defects of hot-rolled strip steel, can solve problems such as the failure to perform online prediction of edge linear defects, and achieve the goal of improving the core competitiveness of products, The effect of fast execution speed and reduced clipping rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

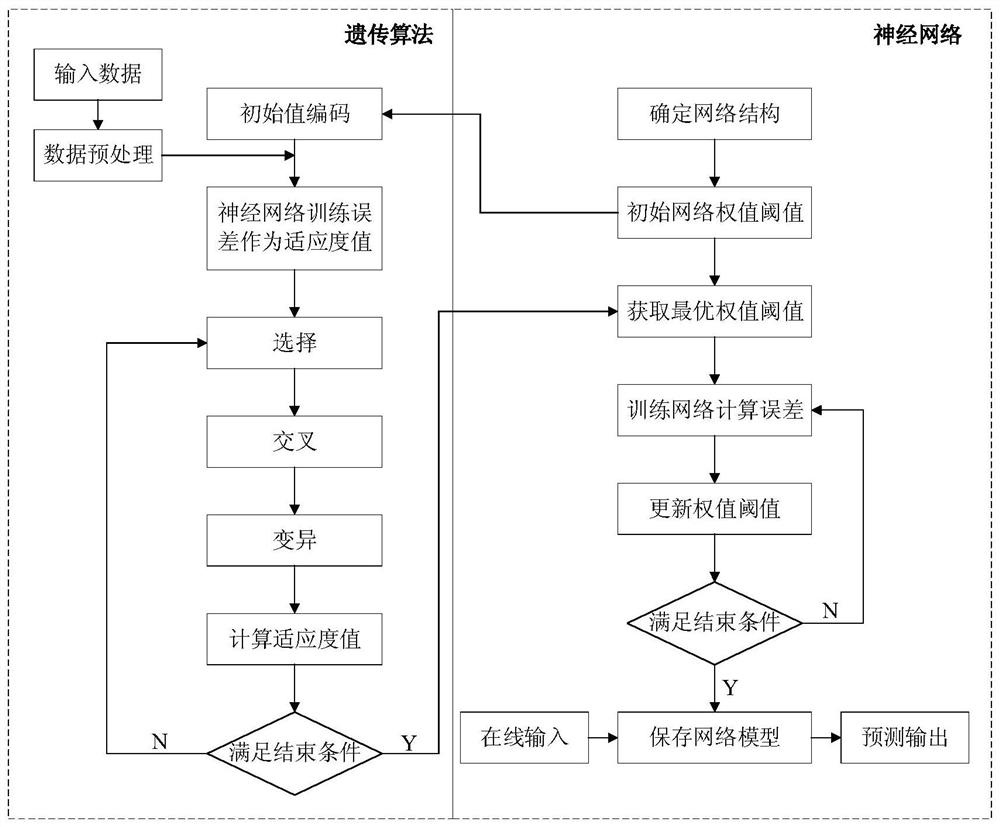

[0055] Such as figure 1 As shown, it is a flow chart of an intelligent online prediction method for a hot-rolled strip edge linear defect of the present invention, which specifically includes the following steps:

[0056] S1. Collect production data of hot-rolled strip steel as sample data and preprocess the sample data:

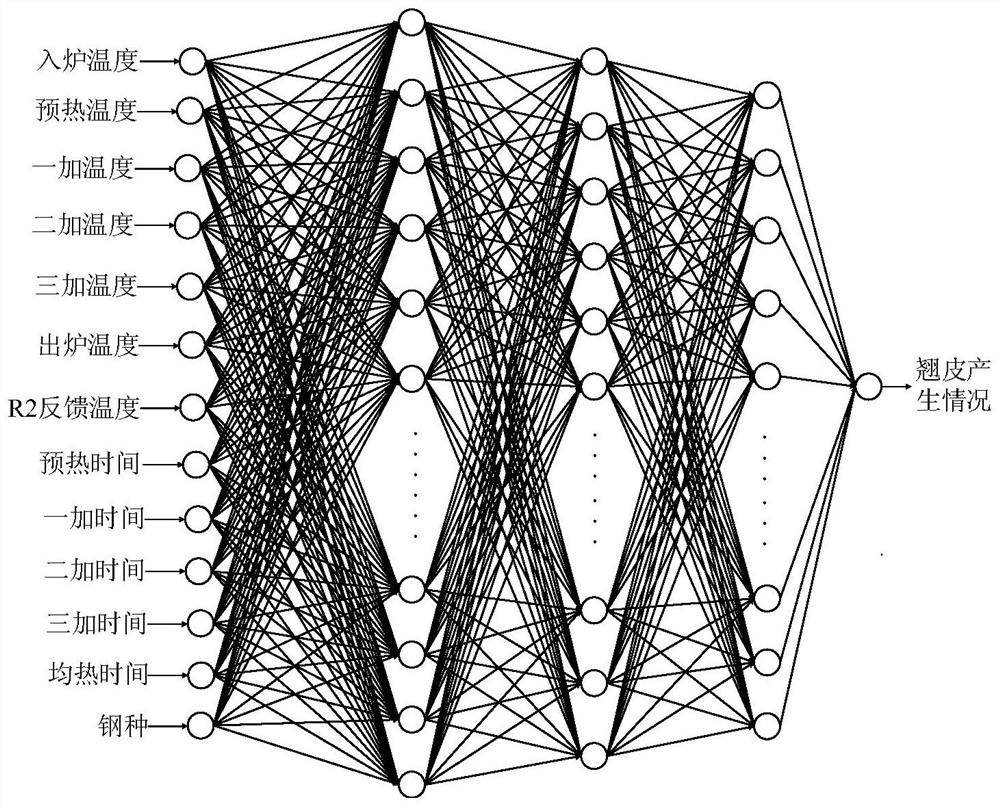

[0057] S11. Collect on-site actual data and establish an original data set, specifically including: furnace entry temperature T f , Preheating section temperature T p , plus temperature T 1 , two plus temperature T 2 , three plus temperature T 3 , out of furnace temperature T o , R2 feedback temperature T R , warm-up time S R , one plus time S 1 , two plus time S 2 , three plus time S 3 , soaking time S a And the steel type m and the corresponding occurrence of linear defects O, where 0 represents the occurrence of linear defects, 1 repres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com