Integrated box body for oil well transformer platform

A technology for transformers and boxes, which is applied in the field of integrated boxes for oil well transformers, can solve the problems of large space occupied by fuses, large space, inconvenient installation and transportation of drop-out fuses, etc., and achieves optimized floor space, The overall structure is stable and the effect of preventing shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

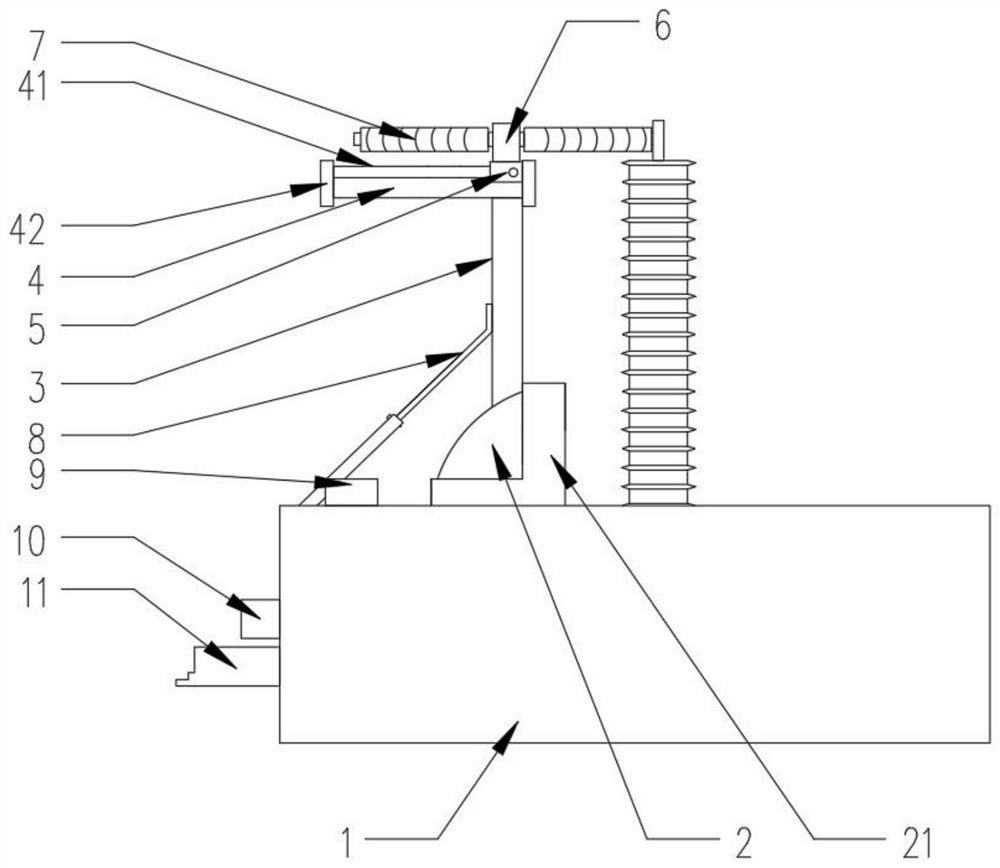

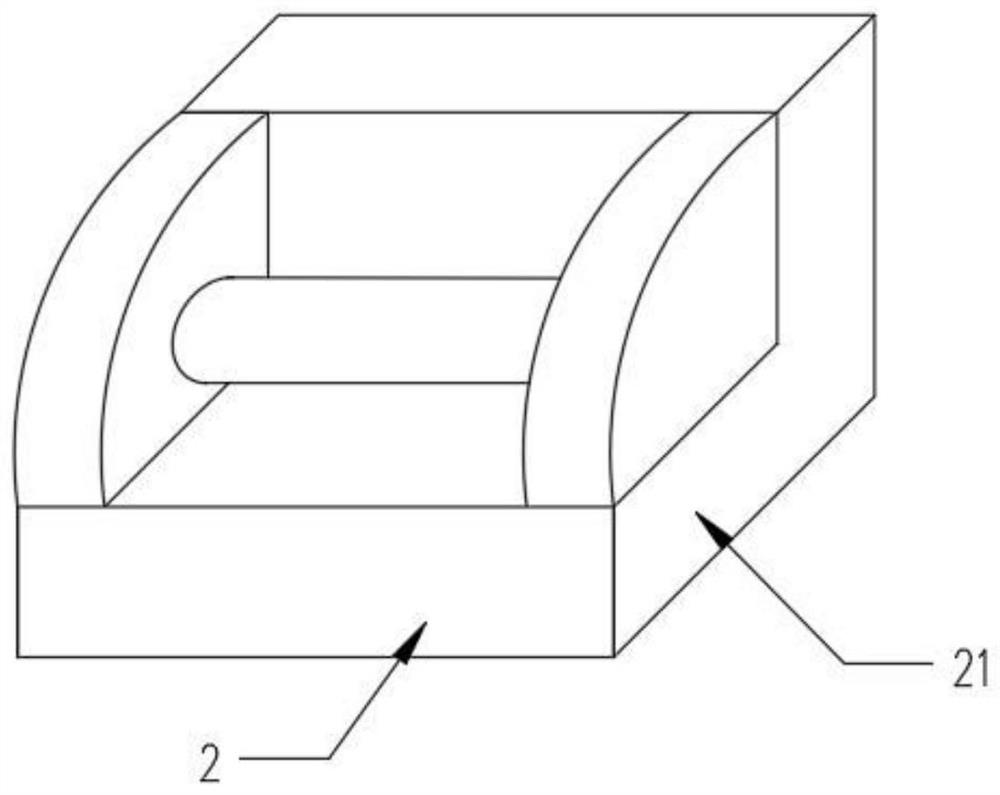

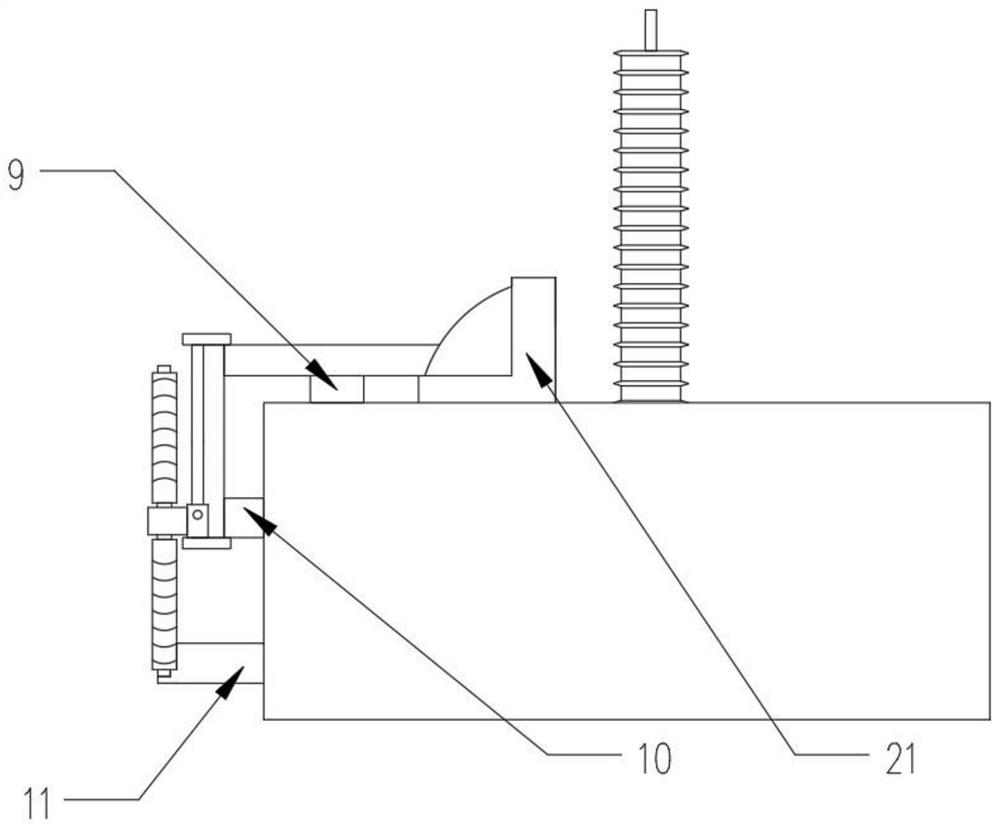

[0030] see figure 1 It is a side-view structure schematic diagram of an integrated box for an oil well transformer platform, including a box 1. A dry-type transformer is installed in the box 1. The small size can further optimize the occupied area and facilitate overall transportation. The actual volume of the box 1 is relatively large. In order to highlight the specific structure and other details in the illustration, we reduced the volume of the box 1 when drawing. The volume of the box 1 is only for illustration. The top of the box 1 is equipped with a high-voltage The bushing, the ratio of the high-voltage bushing to the box is not a true ratio. The top of the high-voltage bushing is provided with a connection hole, and the connection hole can be passed through by the terminal from the horizontal direction. The top of the box 1 is also provided with a support seat 2, The support base 2 is connected with a support rod 3 that can rotate around the support base 2 in a vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com