A kind of micro LED module and preparation method thereof

A technology of quantum dots and quantum wells, which is applied in the field of MicroLED modules and their preparation, can solve the problems of great influence of brightness, color shift, and large temperature change of luminous characteristics, and achieves good waterproofing, sealing and anaerobicity, and high luminous efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

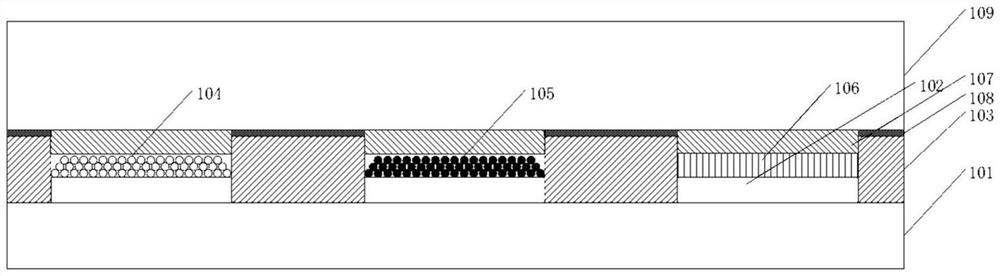

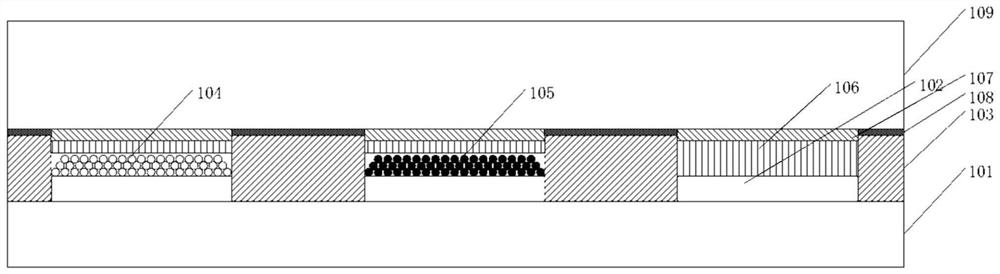

[0050] see figure 1As shown, this embodiment provides a Micro LED module, including a gallium nitride single crystal substrate 101, on which a quantum well light-emitting layer 102 is formed, and the quantum well light-emitting layer 102 is n-type doped. Red quantum dots 104 and green quantum dots 105 are also arranged on the well light-emitting layer 102 .

[0051] Specifically, a hole injection layer 107 is further provided on the quantum well light emitting layer 102 .

[0052] Further, the gallium nitride single crystal substrate 101 is an n-type single crystal substrate; or the gallium nitride single crystal substrate 101 is a non-doped substrate on which n-type gallium nitride is epitaxially formed.

[0053] In this embodiment, the substrate is a gallium nitride single crystal substrate 101, and the Micro LED epitaxially on it has a low dislocation density, has a lower impact on brightness, and has a higher luminous efficiency, so that the Micro LED can operate in a sma...

Embodiment 2

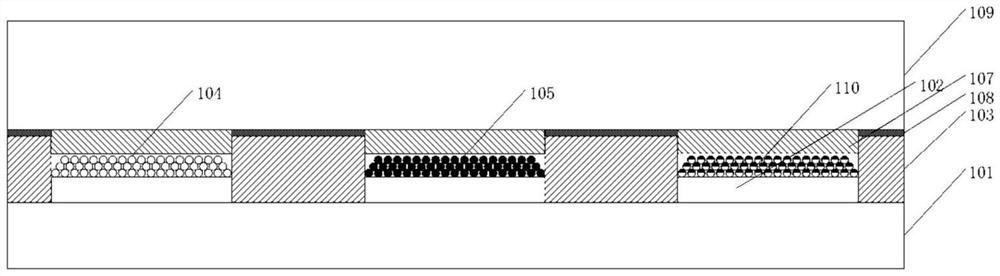

[0064] see image 3 As shown, this embodiment provides a Micro LED module, the quantum well light-emitting layer 102 is a GaN:Si / AlGaN:Si superlattice quantum well, and the quantum well light-emitting layer 102 not only has red quantum dots 104 and green quantum dots 105, blue quantum dots 110 are also provided. The red quantum dots 104, the green quantum dots 105, and the blue quantum dots 110 are perovskite quantum dots.

[0065] It should be noted that this embodiment includes a gallium nitride single crystal substrate 101, an n-type doped quantum well light-emitting layer 102, a black matrix 103, red quantum dots 104, green quantum dots 105, blue quantum dots 110, A hole injection layer 107 , a thin film transistor array 108 and a glass cover 109 .

[0066] In the Micro LED module provided in this embodiment, the substrate is a gallium nitride single crystal substrate 101, and the Micro LED epitaxial on it has a low dislocation density, lower influence on brightness, and...

Embodiment 3

[0069] This embodiment provides a method for preparing a Micro LED module, which can be used to prepare the Micro LED module provided in the above embodiment, which specifically includes the following steps:

[0070] 1. Provide a gallium nitride single crystal substrate 101, form a quantum well light emitting layer 102 thereon, and pattern the quantum well light emitting layer 102;

[0071] 2. Forming a black matrix 103 on the gallium nitride single crystal substrate 101;

[0072] 3. Forming quantum dots of at least one color on the quantum well light-emitting layer 102;

[0073] 4. Form a hole injection layer 107 on the quantum dots.

[0074] In the method for preparing a Micro LED module provided in this embodiment, the substrate is a gallium nitride single crystal substrate 101, and the Micro LED epitaxially thereon has a low dislocation density, lower influence on brightness, and higher luminous efficiency , so that the Micro LED can still emit uniform light with suffici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com