A modular seedling tray precision seeding production line

A precision seeding and production line technology, which is applied to planter parts, fertilizers, seeding equipment, planting methods, etc., can solve the problems of low seeding efficiency and achieve the effects of improving production efficiency, improving efficiency, and convenient combination and movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific implementation of the invention will be further described below in conjunction with the accompanying drawings.

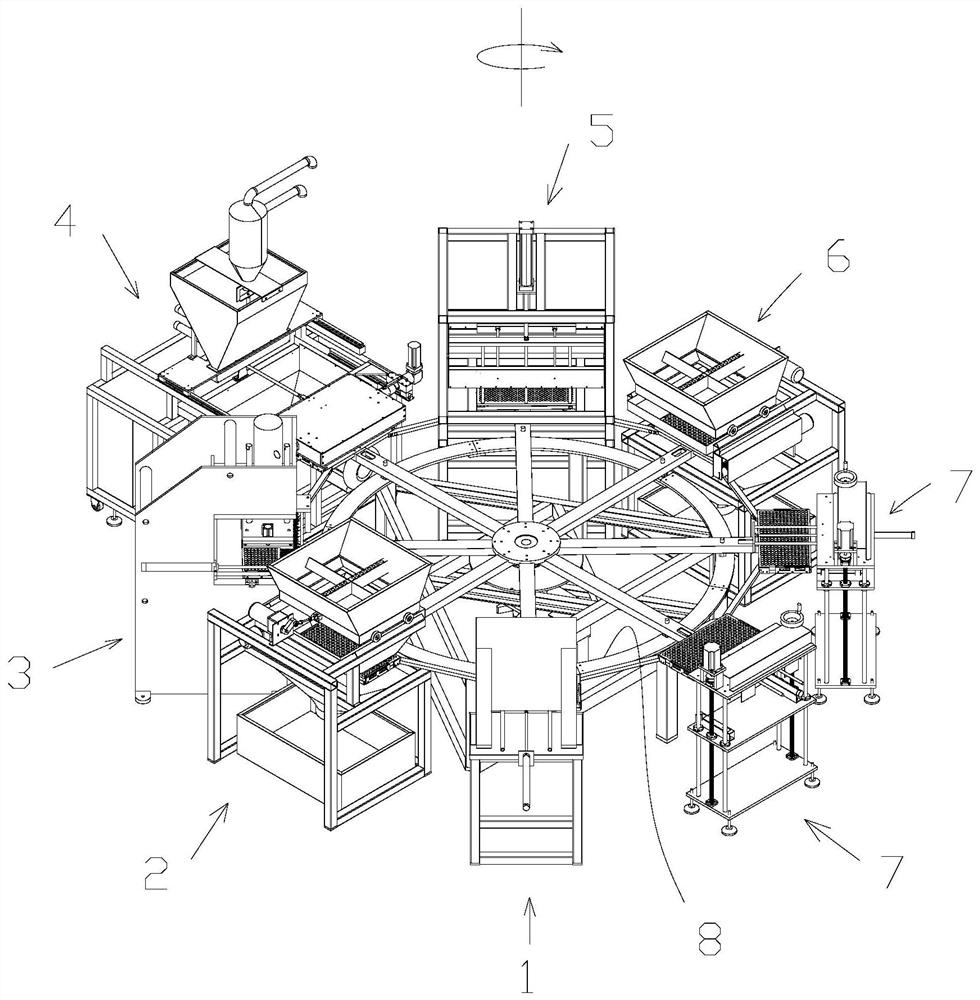

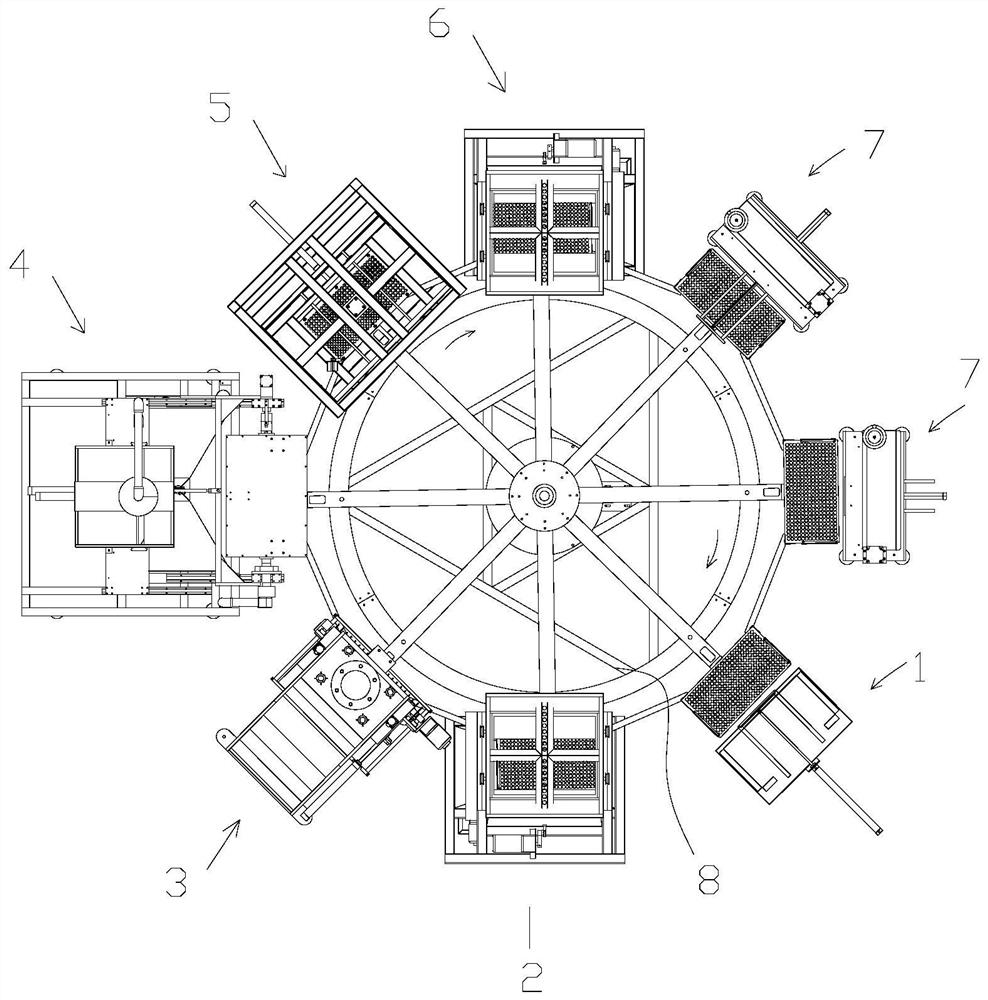

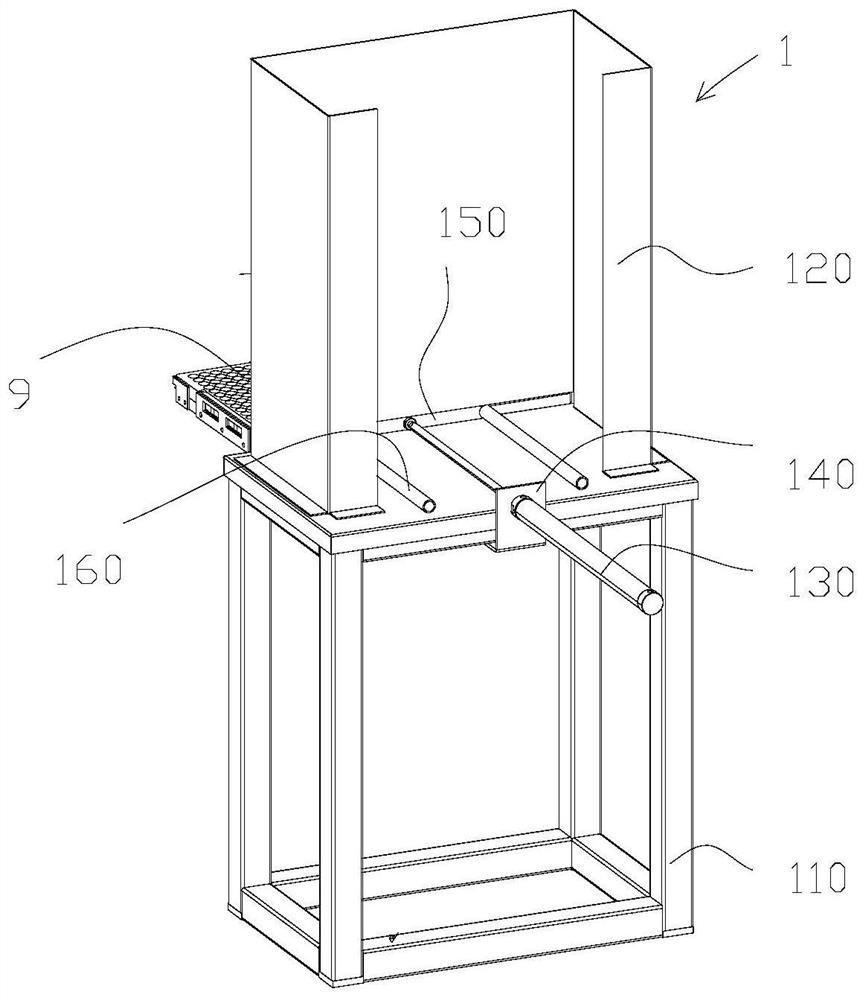

[0046] The present invention provides a precision seeding production line of modular seedling tray 9, which includes a subsoil laying module 2, a subsoil compaction module 3, a seeding module 4, and a topsoil laying module 6; a supporting tray 81 that moves circularly on a horizontal plane To support the seedling tray 9, so that the seedling tray 9 passes through the subsoil laying module 2, the subsoil compaction module 3, the seeding module 4 and the topsoil laying module 6 positioned on the annular track in sequence; the supporting tray 81 is arranged at intervals; The subsoil laying module 2, the subsoil compaction module 3, the seeding module 4 and the topsoil laying module 6 are all demarcated with a working area corresponding to the seedling tray 9; when the seedling tray 9 is in the working area, the supporting tray 81 stops Move until th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com