Quick-disassembly and quick-assembly high-support-stability chair

A technology of stability and chairs, which is applied in the field of chairs, can solve the problems of large transportation space and increase the overall transportation cost, and achieve the effects of reduced transportation space, less difficulty in disassembly, and high support stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

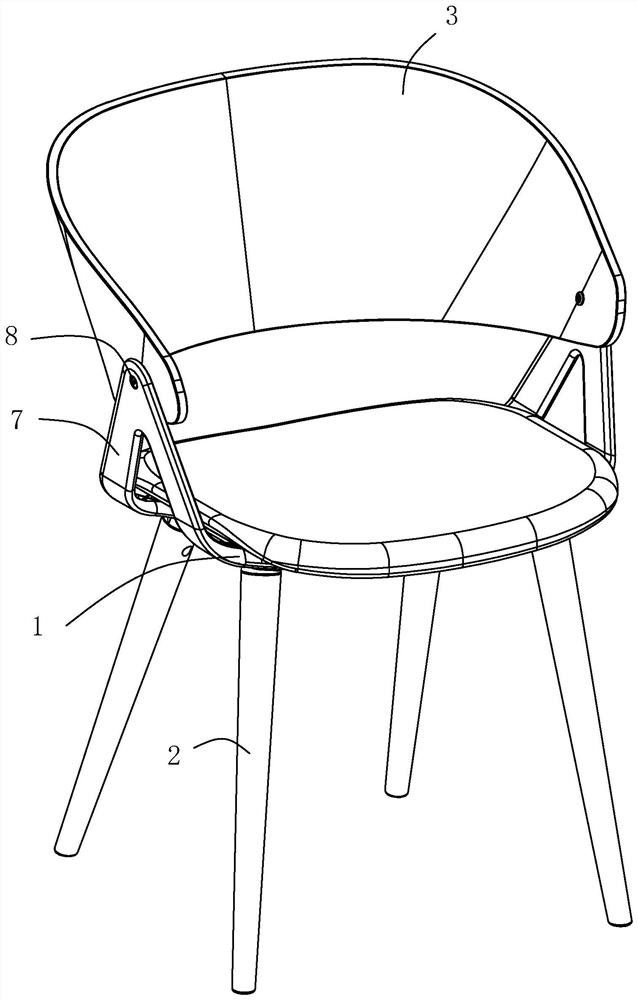

[0052] A chair with high support and stability for quick disassembly and assembly, see figure 1 , including a chair surface 1 and a chair leg 2. The surface and the chair legs 2 are separated, and the chair legs 2 are installed below the chair surface 1, and the chair legs 2 are used to provide support for the chair surface 1.

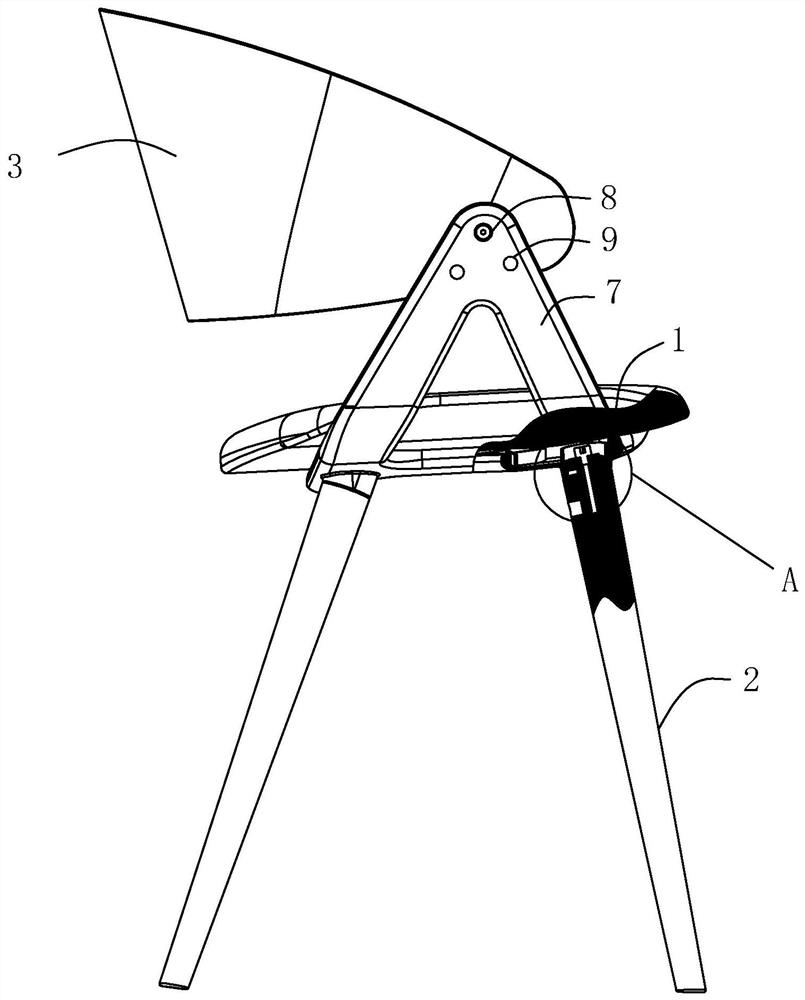

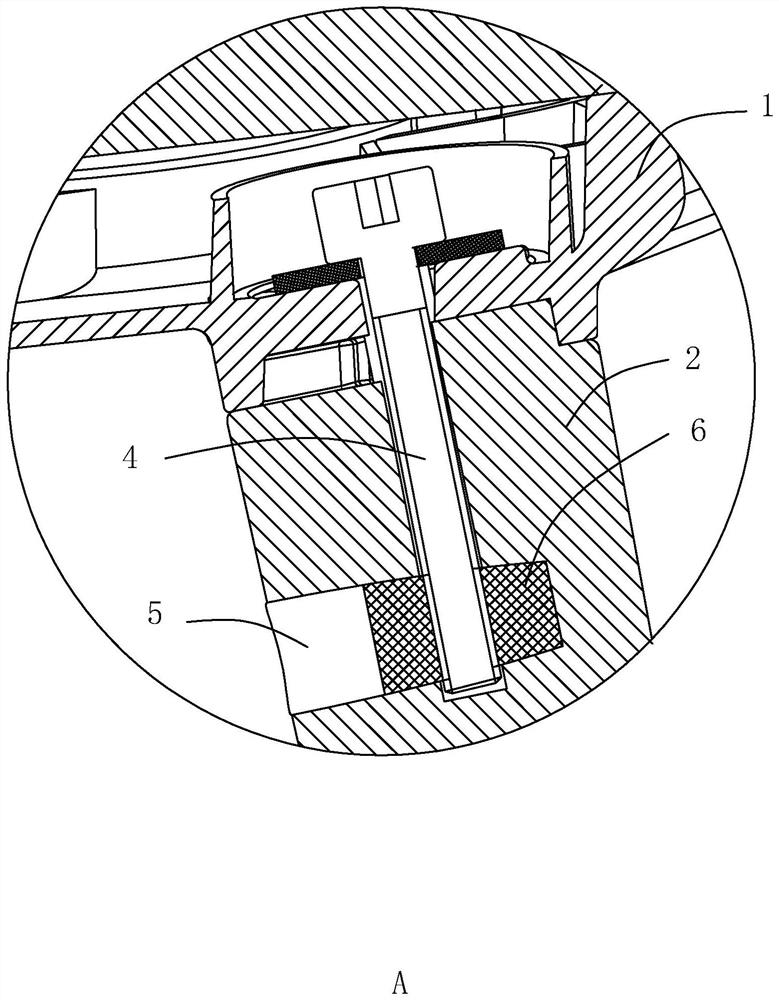

[0053] see figure 2 as well as image 3 , push the chair and be provided with installation hole 5, the aperture of installation hole 5 is gradually reduced in the installation hole 5 holes by installation hole 5 apertures.

[0054] A connecting pin 6 is installed in the mounting hole 5 , and the shape of the connecting pin 6 matches the shape of the mounting hole 5 .

[0055] Corresponding to each chair leg 2, there is a locking bolt 4. The locking bolt 4 passes through the chair surface 1 and the chair leg 2 in turn. The bolt head of the locking bolt 4 penetrates into the mounting hole 5 and is screwed to the connecting pin. 6.

[0056] see Fi...

Embodiment 2

[0058] On the basis of Embodiment 1, the following technical features are added.

[0059] see Figure 5 , is also provided with a chair back 3, the chair surface 1 is integrally bent to the side away from the chair legs 2 to form two support arms 7, and the two ends of the chair back 3 are respectively connected to the two support arms 7 by connecting pieces.

[0060] Among them, see Figure 5 as well as Figure 6 , the connecting piece includes a connecting bolt 8, a positioning pin 9, and the positioning pin 9 is fixedly installed on the support arm 7, and the seat back 3 is provided with a positioning hole 10 for inserting the positioning pin 9, and the connecting bolt 8 is connected to the supporting arm 7 and the support arm 7. Between the chair backs 3.

[0061] Among them, see figure 2 , the number of connecting bolts 8 is one, the number of positioning pins 9 is two, and the positions of connecting bolts 8 and positioning pins 9 form a triangular positioning point...

Embodiment 3

[0063] On the basis of Embodiment 1, the following technical features are added.

[0064] see Figure 7 , a certain angle is formed between the length direction of the locking bolt 4 and the length direction of the chair leg 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com