Automatic interior material stirring equipment for automobile manufacturing and using method thereof

A technology for automobile manufacturing and mixing equipment, applied in chemical instruments and methods, mixer accessories, chemical/physical processes, etc., can solve the problems of uneven and thorough mixing of materials, unable to meet the needs of use, poor mixing effect, etc. Heat conduction efficiency, suitable melting temperature, and the effect of improving stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

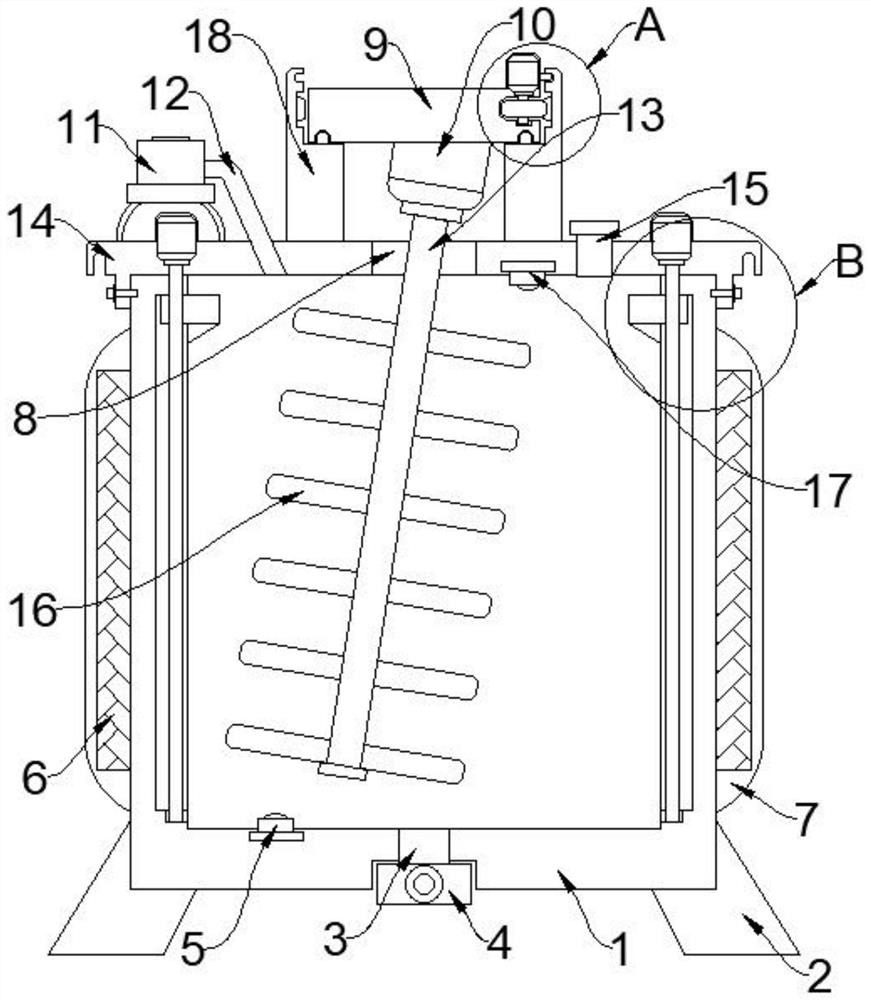

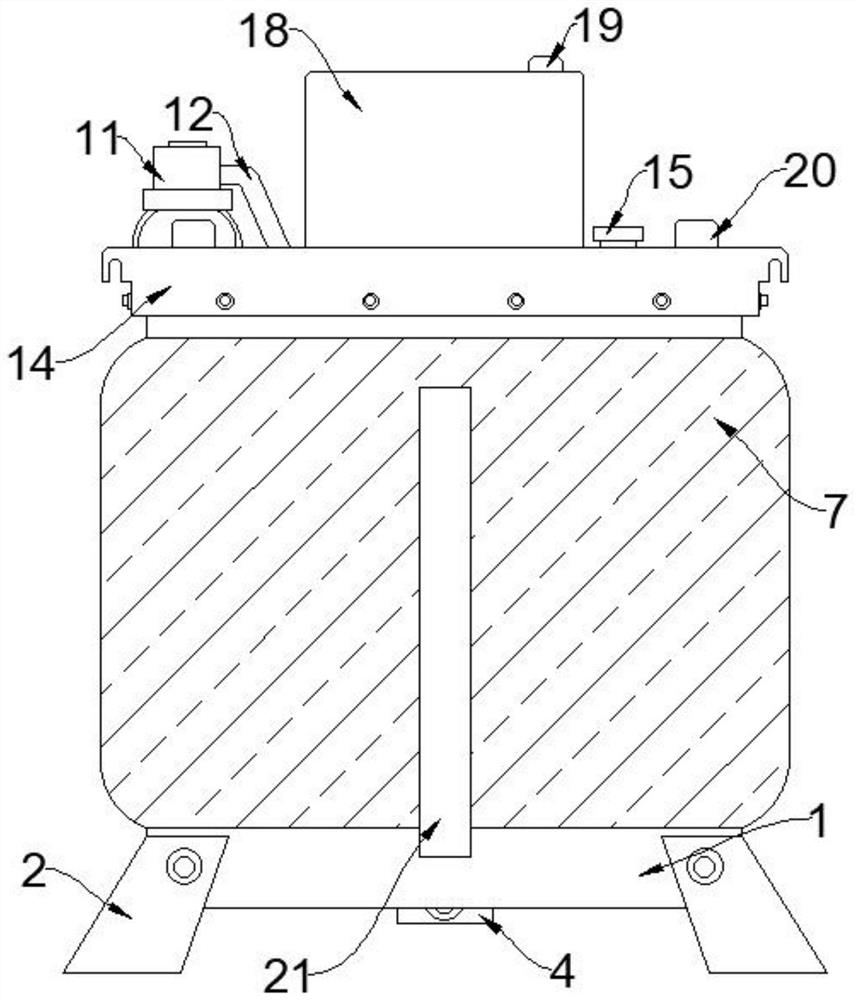

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

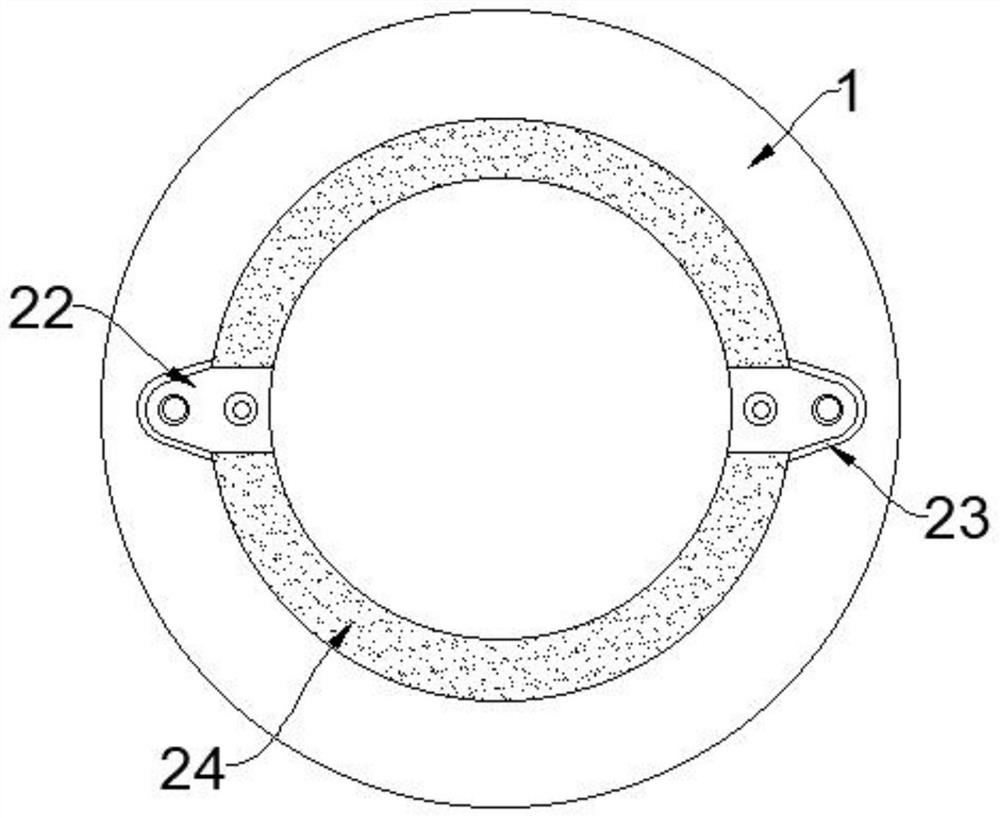

[0028] see Figure 1-5, a kind of embodiment that the present invention provides: be used for the interior decoration automation material mixing equipment of automobile manufacture, comprise mixing bucket 1, be provided with bucket cover 14 above mixing bucket 1, and bucket cover 14 is connected with mixing bucket 1 by screw, The central position of bung 14 is provided with reserved hole 8, and reserved hole 8 can be convenient for rotating shaft 13 to adjust when first motor 10 rotates, and the top of bung 14 is provided with sleeve seat 18, and sleeve seat 18 and The bung 14 is connected by screws, the top of the sleeve seat 18 is provided with a motor mount 9, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com